- SAP Community

- Products and Technology

- Product Lifecycle Management

- PLM Blogs by SAP

- SAP Digital Manufacturing Cloud – Consumption of s...

Product Lifecycle Management Blogs by SAP

Dive into product lifecycle management news, learn about digitalizing PLM for the digital supply chain, and stay informed with product updates from SAP.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member29

Discoverer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

09-23-2020

1:01 PM

Introduction

SAP Digital Manufacturing Cloud is a manufacturing shop floor solution that supports production supervisors and workers during their daily work right on the shop floor where the products get manufactured. It is tightly integrated with SAP S/4 HANA or SAP ERP, where the production orders are planned, inventory is managed, and subsequent supply chain processes are triggered and processed.

With an increasing demand for personalization and traceability of products, there is a clear trend towards lot-size one production. One prerequisite for this is the capability to handle serial numbers throughout the value chain.

In this blog, I will provide you with a step-by-step guide on how to configure SAP Digital Manufacturing Cloud to support serial number data collection during shop floor execution, including inventory updates in SAP S/4 HANA or SAP ERP.

Note: The inventory needs to be set up with the serial number activated.

Prerequisites

Step-by-Step Guide

The configuration will enable the collection of the serial number during the assembly operation, including the update of the consumption with the serial number.

Note: The production order, including Routing and BOM, is replicated from SAP ERP or SAP S/4HANA to SAP Digital Manufacturing Cloud. The serial number for the components is not included.

The serial number will be visible on the physical component itself and during execution, this data needs to be collected to assign it to the finished product.

The custom data fields are used to store the ERP serial data and inventory information collected during assembly.

Create a Data Field

Create a new data type

Attach the custom data type INV_SFC_SERIAL to the Build section of the material. With this configuration, you ensure that during assembly, this data is requested for collection for the specified material.

Manufacturing Execution

Summary

For the consumption of serialized component which is not produced in SAP Digital Manufacturing Cloud, data field 'ERP_SERIAL_NUMBER' need be configured.

SAP Digital Manufacturing Cloud is a manufacturing shop floor solution that supports production supervisors and workers during their daily work right on the shop floor where the products get manufactured. It is tightly integrated with SAP S/4 HANA or SAP ERP, where the production orders are planned, inventory is managed, and subsequent supply chain processes are triggered and processed.

With an increasing demand for personalization and traceability of products, there is a clear trend towards lot-size one production. One prerequisite for this is the capability to handle serial numbers throughout the value chain.

In this blog, I will provide you with a step-by-step guide on how to configure SAP Digital Manufacturing Cloud to support serial number data collection during shop floor execution, including inventory updates in SAP S/4 HANA or SAP ERP.

Note: The inventory needs to be set up with the serial number activated.

Prerequisites

- Set up the integration between SAP Digital Manufacturing Cloud integration and SAP ERP or SAP S/4HANA as described in the SAP Digital Manufacturing Cloud Integration Guide.

- SAP ERP and SAP S/4HANA inventory managed with serial numbers is activated.

- Transfer of Floor Stock Data is set up (see the SAP Digital Manufacturing Cloud Integration Guide - Transfer of Floor Stock Data).

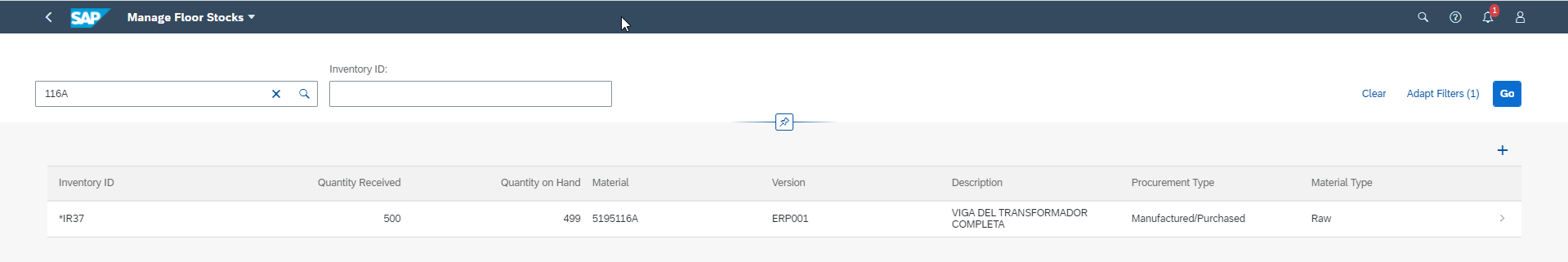

In the picture below, you can see the result of a successful Floor Stock Data Transfer.

Stock Overview in SAP S/4HANA - Transaction /nmmbe

Material Serial Numbers in S/4HANA Inventory - Transaction /nIQ09

Floor Stock Overview in SAP Digital Manufacturing Cloud

Step-by-Step Guide

The configuration will enable the collection of the serial number during the assembly operation, including the update of the consumption with the serial number.

Note: The production order, including Routing and BOM, is replicated from SAP ERP or SAP S/4HANA to SAP Digital Manufacturing Cloud. The serial number for the components is not included.

The serial number will be visible on the physical component itself and during execution, this data needs to be collected to assign it to the finished product.

Step 1: Create Custom Data Fields and Types in SAP Digital Manufacturing Cloud

The custom data fields are used to store the ERP serial data and inventory information collected during assembly.

Create a Data Field

- Open the Manage Data Fields app.

- Create a new data field. The name of the data field must be ERP_SERIAL_NUMBER. The type must be Text. This identifier is used to transfer the data back to ERP and to map it to the inventory.

Create a new data type

- Open the Manage Data Fields app.

- Create the new data type INV_SFC_SERIAL

- Data Type: INV_SFC_SERIAL

- Make sure to collect the Category Assembly

- Add the data fields:

- ERP_SERIAL_NUMBER which you have created in the previous step.

- INVENTORY_ID_SFC (this field is delivered as part of the standard delivery).

Step 2: Enforce data collection on a specific material during assembly

Attach the custom data type INV_SFC_SERIAL to the Build section of the material. With this configuration, you ensure that during assembly, this data is requested for collection for the specified material.

- Open your material in the Manage Material app.

- Go to the Build section.

- In the Data to Collect at Assembly drop-down box, select INV_SFC_SERIAL.

- Click on Save.

Manufacturing Execution

Data Collection during production

- Open one Production Operator Dashboard that has the Component Assembly Plugin configured, e.g. Default Workcenter POD, Default Operation POD.

- Select an SFC.

- Goto Activities.

- Goto Component List.

- Select Assemble for the component which has an external serial number.

- Assemble is opened and shows the data to be collected.

- Open the F4 help for Inventory SFC and and select the inventory ID for your material.

- Enter the serial number: You can entered it manually or scan it from the physical product.

- Click Add to confirm assembly. This triggers goods consumption, and a message is sent back to SAP S/4HANA or ERP to synchronize the stock.

- Synchronized Good Consumption with Serial Number with SAP ERP or SAP S/4HANA

- The information collected during assembly is automatically sent to SAP ERP or SAP S/4HANA.

- You can check the message flow in the Monitor Integration Messages app in SAP Digital Manufacturing Cloud.

- In SAP ERP and SAP S/4HANA, the corresponding material document is generated for inventory deduction.

Summary

For the consumption of serialized component which is not produced in SAP Digital Manufacturing Cloud, data field 'ERP_SERIAL_NUMBER' need be configured.

- Do configuration of integration between SAP Digital Manufacturing Cloud and SAP ERP or SAP S/4HANA on-premise system

- Configure data field 'ERP_SERIAL_NUMBER' into the data type for assembly data collection of Material Master

- Download serialized inventory from SAP ERP or SAP S/4HANA on-premise system to SAP Digital Manufacturing Cloud as floor stock

- Assemble floor stock with Inventory ID and serial number collected in SAP Digital Manufacturing Cloud

- The consumption of serialized component which is not produced in SAP Digital Manufacturing Cloud is synchronized to SAP ERP or SAP S/4HANA on-premise system automatically

- SAP Managed Tags:

- SAP Digital Manufacturing

Labels:

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

Related Content

- How to use Digital Manufacturing MDOs within PPD Example: Where-Used Report with Follow-up Actions in Product Lifecycle Management Blogs by SAP

- Quick Start guide for PLM system integration 3.0 Implementation in Product Lifecycle Management Blogs by SAP

- Striking the Perfect Balance in Product Lifecycle Management Blogs by SAP

- MII configuration and content transport management in Product Lifecycle Management Blogs by SAP

- A day in the life of Mike, a Shop Floor Worker using SAP Digital Manufacturing in Product Lifecycle Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |