- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Revolution not evolution - unlocking the future of...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member67

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

09-18-2020

10:35 AM

CEO’s everywhere are currently contemplating what strategies to adopt in the future.

There is certainly no shortage of ideas from the supplier ecosystem as they too try to respond and adapt to the current situation. Whilst it is true that many of the strategies being proposed represent a significant change to current operating models, I would still argue that these ideas are an evolution.

What I believe we need is a revolution.

The strategy I am advocating in this article is a very simple idea and yet the impact it could have if it achieves large scale adoption would be revolutionary.

I call my idea ‘The Quorum Principle’ and the basic concept is this:

Step 1 – Each manufacturer identifies the five suppliers who, when combined, have the largest impact on the manufacturer achieving its objectives

Figure 1 - Example ‘Quorum’

Step 2 – The manufacturer informs each supplier of their intention to form a strategic Quorum and that they are invited to participate. The Quorum will be collectively responsible for working with the manufacturer to define and deliver the manufacturers strategic goals. They will be expected to work together in an open, co-operative and collaborate manner.

In its simplest form that is it – The Quorum Principle

When I present this idea to people for the first time there is usually a very long silence.

What follows is a fascinating debate. The thing that excites me most about this idea is that their first reaction is an emotional one not a logical one. They either love it or hate it and are passionate either way. Thankfully, the vast majority seem to love it. I realise however that I might just be in an echo chamber of like-minded people so the only way to really test it is to go public.

I am also fully aware of the enormous challenges this strategy faces. There are a multitude of barriers to success and obstacles to overcome. I have thought long and hard about these challenges and in every case I think there are solutions. I also firmly believe that this has to be better than the status quo where large transformation projects typically:

There are obviously far too many details to cover in this article but there are a few key points of view that I want to convey in order to stimulate the debate:

In the example shown in Figure 1, each supplier has a tremendous amount of value to bring in their specific domain. However valuable that individual contribution is, I would argue that the value of the groups combined expertise is far greater than the sum of the parts.

I really want to stress that there is no ‘Dream Team’ combination of suppliers that will fit the needs of every manufacturer. What I am advocating is a process and an approach, not a specific group of vendors. The right combination of ‘players’ needed to form The Quorum will always be manufacturer specific. It will be dependent on the manufacturer’s own situation and their own needs.

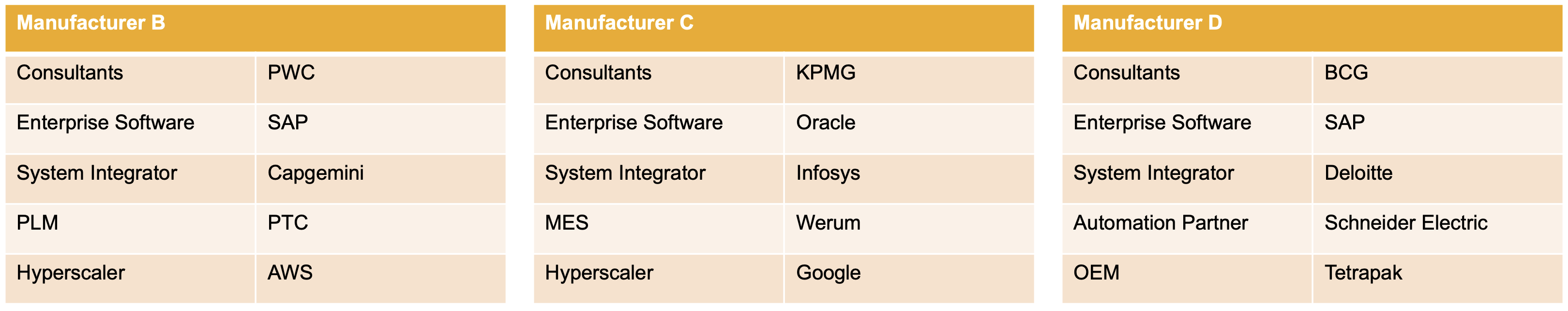

Figure 2 – Example manufacturer specific Quorums

All manufacturers will also have far more than five strategic suppliers. My proposal is that the suppliers are grouped into Tiers. The Tier 1 group work with the client to drive the strategy but the governance model would enable other suppliers to be brought in to contribute in exactly the same spirit of collaboration and co-operation.

The majority of people will also understand that in almost any scenario there will be areas of competitive overlap between the suppliers. The manufacturer has to be very clear in defining the scope and area of responsibility for each supplier. If an area is not defined and two or more suppliers could provide a solution then that area is ringfenced and a competitive process is followed in parallel to the normal business of the group. The client’s decision is respected and that area also then becomes a defined area.

This is by far the most important point.

For this strategy to work it has to be mandated by the manufacturer with full executive sponsorship. There are two reasons for this.

Firstly, I don’t think it is possible for this to be driven from the supplier ecosystem. There is no individual supplier that has the ability to ‘sell’ this idea to all the other suppliers and form such a complicated coalition. There are too many issues related to competition, trust and commercial aspects. Forming a two-way partnership in the supplier ecosystem is challenging enough. A six-way partnership would be exponentially more difficult. That does not mean however that people like me and others in the ecosystem are not trying or willing to drive this because they are. I am simply trying to be realistic.

Secondly, I also think it would be very difficult to make this work from a departmental level inside a manufacturer. Manufacturers also face internal challenges relating to jurisdiction, budget and ownership that would also make it almost impossible to achieve if driven by an individual functional area.

Only the manufacturers executive leadership can provide the mandate to make this happen.

So what next?

My ask is simple:

To learn more about Intelligent Manufacturing, you can download the recent MPI Group research on how to drive agility and productivity in Manufacturing with Industry 4.0. Click here.

There is certainly no shortage of ideas from the supplier ecosystem as they too try to respond and adapt to the current situation. Whilst it is true that many of the strategies being proposed represent a significant change to current operating models, I would still argue that these ideas are an evolution.

What I believe we need is a revolution.

The strategy I am advocating in this article is a very simple idea and yet the impact it could have if it achieves large scale adoption would be revolutionary.

I call my idea ‘The Quorum Principle’ and the basic concept is this:

Step 1 – Each manufacturer identifies the five suppliers who, when combined, have the largest impact on the manufacturer achieving its objectives

Figure 1 - Example ‘Quorum’

Step 2 – The manufacturer informs each supplier of their intention to form a strategic Quorum and that they are invited to participate. The Quorum will be collectively responsible for working with the manufacturer to define and deliver the manufacturers strategic goals. They will be expected to work together in an open, co-operative and collaborate manner.

In its simplest form that is it – The Quorum Principle

When I present this idea to people for the first time there is usually a very long silence.

What follows is a fascinating debate. The thing that excites me most about this idea is that their first reaction is an emotional one not a logical one. They either love it or hate it and are passionate either way. Thankfully, the vast majority seem to love it. I realise however that I might just be in an echo chamber of like-minded people so the only way to really test it is to go public.

I am also fully aware of the enormous challenges this strategy faces. There are a multitude of barriers to success and obstacles to overcome. I have thought long and hard about these challenges and in every case I think there are solutions. I also firmly believe that this has to be better than the status quo where large transformation projects typically:

- Take longer than expected

- Cost more than expected

- Deliver less value than expected

There are obviously far too many details to cover in this article but there are a few key points of view that I want to convey in order to stimulate the debate:

- Aristotle - “The whole is greater than the sum of the parts”

In the example shown in Figure 1, each supplier has a tremendous amount of value to bring in their specific domain. However valuable that individual contribution is, I would argue that the value of the groups combined expertise is far greater than the sum of the parts.

- There is no one size fits all ‘Dream Team’

I really want to stress that there is no ‘Dream Team’ combination of suppliers that will fit the needs of every manufacturer. What I am advocating is a process and an approach, not a specific group of vendors. The right combination of ‘players’ needed to form The Quorum will always be manufacturer specific. It will be dependent on the manufacturer’s own situation and their own needs.

Figure 2 – Example manufacturer specific Quorums

- Tiering

All manufacturers will also have far more than five strategic suppliers. My proposal is that the suppliers are grouped into Tiers. The Tier 1 group work with the client to drive the strategy but the governance model would enable other suppliers to be brought in to contribute in exactly the same spirit of collaboration and co-operation.

- Co-opetition

The majority of people will also understand that in almost any scenario there will be areas of competitive overlap between the suppliers. The manufacturer has to be very clear in defining the scope and area of responsibility for each supplier. If an area is not defined and two or more suppliers could provide a solution then that area is ringfenced and a competitive process is followed in parallel to the normal business of the group. The client’s decision is respected and that area also then becomes a defined area.

- Mandate

This is by far the most important point.

For this strategy to work it has to be mandated by the manufacturer with full executive sponsorship. There are two reasons for this.

Firstly, I don’t think it is possible for this to be driven from the supplier ecosystem. There is no individual supplier that has the ability to ‘sell’ this idea to all the other suppliers and form such a complicated coalition. There are too many issues related to competition, trust and commercial aspects. Forming a two-way partnership in the supplier ecosystem is challenging enough. A six-way partnership would be exponentially more difficult. That does not mean however that people like me and others in the ecosystem are not trying or willing to drive this because they are. I am simply trying to be realistic.

Secondly, I also think it would be very difficult to make this work from a departmental level inside a manufacturer. Manufacturers also face internal challenges relating to jurisdiction, budget and ownership that would also make it almost impossible to achieve if driven by an individual functional area.

Only the manufacturers executive leadership can provide the mandate to make this happen.

So what next?

My ask is simple:

- Share this article.

- If you are an SAP client or partner and want to discuss this further then please contact me

- If you think you are a competitor you might be surprised so also please contact me

The momentum behind this idea is already building. I am absolutely convinced this is the right way to go but I could be completely wrong so the faster we can test it the better. I explained in my previous article why I felt we have to do things completely differently in the future but I didn’t say how.

Hopefully, this is how.

To learn more about Intelligent Manufacturing, you can download the recent MPI Group research on how to drive agility and productivity in Manufacturing with Industry 4.0. Click here.

- SAP Managed Tags:

- MAN (Manufacturing),

- Digital Transformation

Labels:

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

22 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

156 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

217 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

Related Content

- 🚀 BREAKING FRONTIERS: SAP S/4HANA CLOUD & AI CRAFTING FUTURE WORKSPACES 🌐 in Enterprise Resource Planning Blogs by SAP

- Cloud ERP Close-Up: Transforming Finance-Led ERP and Service-Centric Industries with Cloud ERP Solutions in Enterprise Resource Planning Blogs by SAP

- Enhancing Sales Efficiency- AI powered Sales Order Autocomplete in SAP S/4HANA Cloud, Public Edition 2308 Release: Addressing Customer Challenges and Driving Benefits in Enterprise Resource Planning Blogs by SAP

- Unlocking Seamless Maintenance Planning using SAP S/4HANA On-Prem, SAP Business Network Asset Collaboration and SAP Build Process Automation in Enterprise Resource Planning Blogs by SAP

- Unlocking Business Efficiency: Leveraging AI-powered Corrective Actions and S/4HANA for Real-time Manufacturing Variance Analysis in Enterprise Resource Planning Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 12 | |

| 11 | |

| 10 | |

| 8 | |

| 7 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 3 |