- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Why Capacity Requirement Planning is integral to P...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member30

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

09-07-2020

12:58 PM

Dave: Mike I can see that you have released few production orders for this week. I’m afraid we wouldn’t be able to produce these orders as there is capacity overload. Also the orders are not scheduled correctly.

Mike: What do you mean Dave? I have released the orders from MRP.

Dave: Yes, but MRP is based on infinite capacity model

Mike: Infinite Capacity model? Could you please help me understand what that is ?

Dave: Basically MRP ignores any capacity constraints which means MRP only focuses on the quantity of the material to be produced. MRP only suggests the dates on which the material is to be produced.

Mike: Does this mean that results from MRP are incorrect? What can we do to prevent such situation in future ?

Dave: As I said earlier MRP executes on the principle of infinite capacity. Thus as per Best practice we should run Capacity Planning and Leveling after MRP run.

The above discussion is a transcript of a daily production stand-up meeting. Dave is production supervisor who is discussing production schedule with Mike who is a new production planner. Mike converted the planned order from MRP to production orders without considering capacity constraints. This resulted in capacity overload which means orders couldn’t be produced on time which would eventually result in delivery delays to the customer. That’s why it is extremely important to run capacity requirement planning. Once the planned orders from MRP are converted to production orders then capacity planning and evaluation should be carried out as MRP runs on the principle of Infinite capacity.

In this blog we’ll discuss some details of capacity requirement planning.

First thing first, the objective of Capacity Requirement Planning is to understand:

All the capacity relevant data is maintained in ‘Capacity’ tab in work center which is used to calculate the available capacity of the work center. Also, you could assign Factory Calendar to the work center so that capacity is only generated for working days while production on non-working days/holidays is not considered.

In the below screenshot you can see that SAP has offered many transactions in the capacity planning module. Each transaction code is designed for a specific use-case for example CM01 is designed to evaluate load at work center while CM21 is for leveling capacity requirements.

Personally I don’t think most of these transactions are really useful from an end-user point of view. I rather prefer CM25 as a one-stop shop which can be used for capacity leveling in a graphical format.

But before that we need to understand how capacity load is generated on a work center.

In Routing we maintain operating time for each activity on a work center. These operating times are used for calculating

load on the work center for a given production order. However ‘Control Key’ plays a very vital role here. Only the operations on work centers with control keys which have ‘Detailed Capacity Requirements’ activated generates capacity load.

Now let’s have a look at CM25 which can be used for capacity leveling.

Below screenshot displays production orders converted from planned orders after the MRP run. However these orders are not dispatched.

In the Order (pool) you can see multiple orders scheduled to run at the same time on work center. However it is practically not possible to product multiple orders at the same time on a single operation.

Now, select the orders and dispatch. Orders are dispatched on the work centers.

Now, the orders are dispatched. In the below screenshot you can see that only 1 operation/order is scheduled to run on a work center at a time. You can display this information in two different formats like work center view and order (dispatched) view.

Order Dispatch means capacity requirement planning is performed on the orders which means system calculates required capacity from the Routing and schedules the orders/operations to be executed on a work center. Time is calculated to the exact requirement of hour/minutes/seconds based on the order quantity & time maintained for each operation in the routing and accordingly operations are scheduled on the work center. CRP makes sure that only one operation/order is loaded on a work center.

CM25 offers some very interesting features. Here are some of my favorite features:

You can use Strategy profile to control the dispatching of operations. If gives you a flexibility to select various parameters like:

Conclusion: MRP run is executed based on Infinite Capacity Model thus it is extremely important to use Capacity Requirement Planning. This will help to improve the utilization of available capacity and ensure on-time production.

SAP Press E-Bite by Himanshu Goel

This E-Bite gives a deep insight to Material master. No record is more central to SCM in SAP S/4HANA than the material master, so uncover the key data stored in each material master view with this book! Start with the basic data and classifications that span supply chain and financials processes. Then dig into key fields for sales, procurement, production, financials, and more. Learn what’s changed since SAP ERP: characters added, fields removed, new material types offered, and so on.

You can order your copy on https://bit.ly/3t8qYI6. You can use the coupon code MMSS10 to avail a discount of 10%.

Mike: What do you mean Dave? I have released the orders from MRP.

Dave: Yes, but MRP is based on infinite capacity model

Mike: Infinite Capacity model? Could you please help me understand what that is ?

Dave: Basically MRP ignores any capacity constraints which means MRP only focuses on the quantity of the material to be produced. MRP only suggests the dates on which the material is to be produced.

Mike: Does this mean that results from MRP are incorrect? What can we do to prevent such situation in future ?

Dave: As I said earlier MRP executes on the principle of infinite capacity. Thus as per Best practice we should run Capacity Planning and Leveling after MRP run.

The above discussion is a transcript of a daily production stand-up meeting. Dave is production supervisor who is discussing production schedule with Mike who is a new production planner. Mike converted the planned order from MRP to production orders without considering capacity constraints. This resulted in capacity overload which means orders couldn’t be produced on time which would eventually result in delivery delays to the customer. That’s why it is extremely important to run capacity requirement planning. Once the planned orders from MRP are converted to production orders then capacity planning and evaluation should be carried out as MRP runs on the principle of Infinite capacity.

In this blog we’ll discuss some details of capacity requirement planning.

First thing first, the objective of Capacity Requirement Planning is to understand:

- Which work centers are required for Production?

- How much capacity of a work center is needed for Production?

- When is the capacity of the work center needed?

- Analyze capacity overload/underload situation

All the capacity relevant data is maintained in ‘Capacity’ tab in work center which is used to calculate the available capacity of the work center. Also, you could assign Factory Calendar to the work center so that capacity is only generated for working days while production on non-working days/holidays is not considered.

In the below screenshot you can see that SAP has offered many transactions in the capacity planning module. Each transaction code is designed for a specific use-case for example CM01 is designed to evaluate load at work center while CM21 is for leveling capacity requirements.

Personally I don’t think most of these transactions are really useful from an end-user point of view. I rather prefer CM25 as a one-stop shop which can be used for capacity leveling in a graphical format.

But before that we need to understand how capacity load is generated on a work center.

In Routing we maintain operating time for each activity on a work center. These operating times are used for calculating

load on the work center for a given production order. However ‘Control Key’ plays a very vital role here. Only the operations on work centers with control keys which have ‘Detailed Capacity Requirements’ activated generates capacity load.

Now let’s have a look at CM25 which can be used for capacity leveling.

Below screenshot displays production orders converted from planned orders after the MRP run. However these orders are not dispatched.

In the Order (pool) you can see multiple orders scheduled to run at the same time on work center. However it is practically not possible to product multiple orders at the same time on a single operation.

Now, select the orders and dispatch. Orders are dispatched on the work centers.

Now, the orders are dispatched. In the below screenshot you can see that only 1 operation/order is scheduled to run on a work center at a time. You can display this information in two different formats like work center view and order (dispatched) view.

Order Dispatch means capacity requirement planning is performed on the orders which means system calculates required capacity from the Routing and schedules the orders/operations to be executed on a work center. Time is calculated to the exact requirement of hour/minutes/seconds based on the order quantity & time maintained for each operation in the routing and accordingly operations are scheduled on the work center. CRP makes sure that only one operation/order is loaded on a work center.

CM25 offers some very interesting features. Here are some of my favorite features:

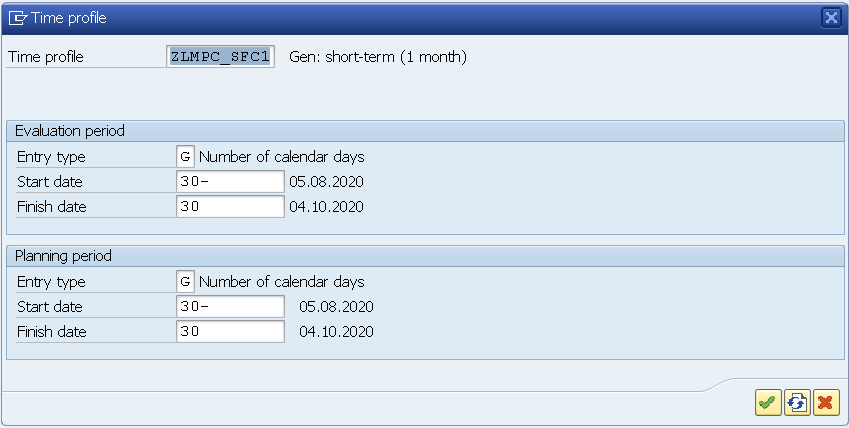

- Time Profile: you can choose the planning time horizon for which you want to run the capacity requirement planning.

- Time Scales: CM25 offers the option of changing the scale on planning table as per user preference. The Time axis of the planning board can be displayed in Hourly/Daily/Weekly scales. This gives flexibility to evaluate planning situation from short term to long term planning horizon.

- Strategy Profile:

You can use Strategy profile to control the dispatching of operations. If gives you a flexibility to select various parameters like:

- Parameters to control scheduling, that is, the dispatching of individual operations. You can control the parameters like Finite scheduling or Planning direction forwards or Dispatch at earliest point in time etc

- Parameters to control data like Period Split and Queue Time.

- Parameters to control Dispatching like:

- The following functions are available:

- Sorting of operations to be dispatched

- Consider operation sequence in the order

- Operation date check

- Change production version in event of an error

- Midpoint scheduling

Conclusion: MRP run is executed based on Infinite Capacity Model thus it is extremely important to use Capacity Requirement Planning. This will help to improve the utilization of available capacity and ensure on-time production.

SAP Press E-Bite by Himanshu Goel

This E-Bite gives a deep insight to Material master. No record is more central to SCM in SAP S/4HANA than the material master, so uncover the key data stored in each material master view with this book! Start with the basic data and classifications that span supply chain and financials processes. Then dig into key fields for sales, procurement, production, financials, and more. Learn what’s changed since SAP ERP: characters added, fields removed, new material types offered, and so on.

- Explore key material master views in SAP S/4HANA

- Discover material data related to procurement, sales, logistics, and more

- Compare SAP S/4HANA‘s material master with SAP ERP’s version

You can order your copy on https://bit.ly/3t8qYI6. You can use the coupon code MMSS10 to avail a discount of 10%.

- SAP Managed Tags:

- MAN Production Planning (PP)

14 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- PIR date at start of month in Enterprise Resource Planning Q&A

- Collective processing of PR's generated by MRP in S4 Hana Public Cloud in Enterprise Resource Planning Q&A

- The project system should automatically update the equipment usage counter in Enterprise Resource Planning Q&A

- Subcontracting requirements does not consider plant's inventory in Enterprise Resource Planning Q&A

- Kanban with production orders: Scheduling of orders in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |