- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- QM with EWM integration for inspection process aga...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member65

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

07-30-2020

2:34 PM

Purpose:

This blog will help you to do configuration and set up of Master data to generate the inspection lots by using EWM inspection types 1701 & 1704.

While working for QM implementation with EWM integration, I struggled bit to get the relevant documents/ blog/ information to configure the integration between QM and EWM in S/4 HANA 1809. That bit of struggle made me to write this blog to help consultants from QM community, who are getting into S/4 HANA environment from ECC.

As you aware, we must use 1701 inspection type for incoming goods inspection and 1704 for Manufacturing goods inspection in S/4 HANA 1809 if the storage locations are EWM Managed. We must activate these inspection types in QM view of Material master as Like 01 & 04 inspection types, which we do for inventory Managed storage locations.

Even though, we have EWM & QM in Same box in S/4 HANA 1809, instances are different, so we must do relevant configuration in “SCM Extended Warehouse Management”

1.1 Generate Inspection Object types version:

This configuration makes the generation of inspection document which create the inspection lot in S/4 HANA based inbound inspection process from the inspection rule. We have different IOTs in S/4 HANA 1809 Like

OT 1: Preliminary Inspection Inbound Delivery

IOT 2: Counting Inbound Delivery

IOT 3: Q-Inspection Returns Delivery

IOT 4: Q-Inspection Product/Batch Inbound Delivery

IOT 5: Q-Inspection Product/Batch Warehouse-Internal

IOT 6: Preliminary Inspection Handling Unit

This blog is focused on IOT-4 so will see the configuration part for IOT-4

IOT 4: Q-Inspection Product/Batch Inbound Delivery: This is to generate the inspection lot generation from Goods receipt from Inbound delivery, Acceptance sampling, Presampling.

Here we should have below entry for Inspection Object Type (IOT)

1.2 Maintain Inspection Object types version:

This configuration is to Define properties that should be used to search for an appropriate inspection rule and bring these into a sequence relevant for the inspection rule determination, according to the level of detail for your search. The roughest criterion begins with 1.

1.3 Warehouse-Dependent Activation of Inspection Object Type

This is the configuration to be done each warehouse. if business need early inspection lot, we must select presampling field. if Business want to do GR after inspection lot completion then we must select “Accept sampling” field.

Based on selection of I-Lot set up, Inspection rule need to be created which is master data.

1.4 Maintain Inspection rule Group:

By this configuration we can create the inspection rule group which can be maintained in inspection rule and Warehouse execution tab of Material master data so that we can make use of the relevant inspection rule for the material which falls under the same category.

1.5 Define Work centre

This configuration is required to take the usage decision at handling unit level for each Warehouse otherwise stock posting will not be happening through follow up action.

Follow above path and Maintain the work centre for warehouse

1.6 Define follow up actions

Follow up actions are Mandatory configuration, which we must assign to UD code for EWM inspection type. Use the below path to configure the follow up actions

Here we have standard follow up action given by SAP. Each follow up action contains relevant Function module, which post the stock in background to defined stock type.

1.7 Configuration of Code groups for Usage decision

We must maintain the code groups for usage decision so that we can use those Code groups while doing usage decision for inspection lot.

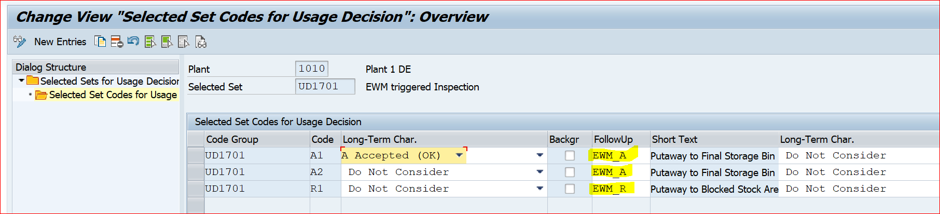

1.8 Edit Selected Sets for Usage Decisions

We must maintain the selection sets for each plant with above configured code groups.

As mentioned above do the new entries for each plant

Here we must maintain the follow up action for each selected set code as mentioned below

1.9 Assign Logistical Follow-Up Actions

We must assign the follow-up actions for each warehouse. These follow-up actions call the function module which is assigned for follow up action which will happen in background.

same way, we must assign the remaining follow-up actions for each warehouse so that when we do usage decision, system call the assigned follow-up actions to post the stock from Quality inspection to relevant stock type based on UD code.

2.Master data Set Up

2.1 We must activate EWM inspection types like 1701 for incoming goods against PO and 1704 for Goods receipt from Production order/ Process order

2.2 We must create the inspection plan with usage 9 for the material

2.3 we must create the inspection rule with for each warehouse wherever QM needed. For more details about inspection rule you can look in the below blog

https://blogs.sap.com/2020/07/16/inbound-inspection-process-in-qm-with-ewm-integration-in-s-4-hana-1...

After Maintaining the above-mentioned configuration and Master data set up, we can perform the inspection lot Processing as per the below Process flow.

Conclusion: By following mentioned configuration and Master data set up, we can complete the QM integration with EWM with respect to Goods receipt process from inbound delivery

This blog will help you to do configuration and set up of Master data to generate the inspection lots by using EWM inspection types 1701 & 1704.

While working for QM implementation with EWM integration, I struggled bit to get the relevant documents/ blog/ information to configure the integration between QM and EWM in S/4 HANA 1809. That bit of struggle made me to write this blog to help consultants from QM community, who are getting into S/4 HANA environment from ECC.

As you aware, we must use 1701 inspection type for incoming goods inspection and 1704 for Manufacturing goods inspection in S/4 HANA 1809 if the storage locations are EWM Managed. We must activate these inspection types in QM view of Material master as Like 01 & 04 inspection types, which we do for inventory Managed storage locations.

- Configuration:

Even though, we have EWM & QM in Same box in S/4 HANA 1809, instances are different, so we must do relevant configuration in “SCM Extended Warehouse Management”

1.1 Generate Inspection Object types version:

This configuration makes the generation of inspection document which create the inspection lot in S/4 HANA based inbound inspection process from the inspection rule. We have different IOTs in S/4 HANA 1809 Like

OT 1: Preliminary Inspection Inbound Delivery

IOT 2: Counting Inbound Delivery

IOT 3: Q-Inspection Returns Delivery

IOT 4: Q-Inspection Product/Batch Inbound Delivery

IOT 5: Q-Inspection Product/Batch Warehouse-Internal

IOT 6: Preliminary Inspection Handling Unit

This blog is focused on IOT-4 so will see the configuration part for IOT-4

IOT 4: Q-Inspection Product/Batch Inbound Delivery: This is to generate the inspection lot generation from Goods receipt from Inbound delivery, Acceptance sampling, Presampling.

Here we should have below entry for Inspection Object Type (IOT)

1.2 Maintain Inspection Object types version:

This configuration is to Define properties that should be used to search for an appropriate inspection rule and bring these into a sequence relevant for the inspection rule determination, according to the level of detail for your search. The roughest criterion begins with 1.

1.3 Warehouse-Dependent Activation of Inspection Object Type

This is the configuration to be done each warehouse. if business need early inspection lot, we must select presampling field. if Business want to do GR after inspection lot completion then we must select “Accept sampling” field.

Based on selection of I-Lot set up, Inspection rule need to be created which is master data.

1.4 Maintain Inspection rule Group:

By this configuration we can create the inspection rule group which can be maintained in inspection rule and Warehouse execution tab of Material master data so that we can make use of the relevant inspection rule for the material which falls under the same category.

1.5 Define Work centre

This configuration is required to take the usage decision at handling unit level for each Warehouse otherwise stock posting will not be happening through follow up action.

Follow above path and Maintain the work centre for warehouse

1.6 Define follow up actions

Follow up actions are Mandatory configuration, which we must assign to UD code for EWM inspection type. Use the below path to configure the follow up actions

Here we have standard follow up action given by SAP. Each follow up action contains relevant Function module, which post the stock in background to defined stock type.

Standard Function modules are assigned to standard follow actions as below

1.7 Configuration of Code groups for Usage decision

We must maintain the code groups for usage decision so that we can use those Code groups while doing usage decision for inspection lot.

1.8 Edit Selected Sets for Usage Decisions

We must maintain the selection sets for each plant with above configured code groups.

As mentioned above do the new entries for each plant

Here we must maintain the follow up action for each selected set code as mentioned below

1.9 Assign Logistical Follow-Up Actions

We must assign the follow-up actions for each warehouse. These follow-up actions call the function module which is assigned for follow up action which will happen in background.

same way, we must assign the remaining follow-up actions for each warehouse so that when we do usage decision, system call the assigned follow-up actions to post the stock from Quality inspection to relevant stock type based on UD code.

2.Master data Set Up

2.1 We must activate EWM inspection types like 1701 for incoming goods against PO and 1704 for Goods receipt from Production order/ Process order

2.2 We must create the inspection plan with usage 9 for the material

2.3 we must create the inspection rule with for each warehouse wherever QM needed. For more details about inspection rule you can look in the below blog

https://blogs.sap.com/2020/07/16/inbound-inspection-process-in-qm-with-ewm-integration-in-s-4-hana-1...

After Maintaining the above-mentioned configuration and Master data set up, we can perform the inspection lot Processing as per the below Process flow.

Conclusion: By following mentioned configuration and Master data set up, we can complete the QM integration with EWM with respect to Goods receipt process from inbound delivery

- SAP Managed Tags:

- PLM Quality Management (QM)

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- Print customer specific inspection plan results on Outbound Certificate of Analysis in SAP QM in Enterprise Resource Planning Q&A

- An introduction into Service Management in S/4HANA Cloud Private Edition in Enterprise Resource Planning Blogs by SAP

- How to Create Outbound Delivery With order reference in SAP VL01N in Enterprise Resource Planning Blogs by Members

- Creation of Outbound Delivery using VL01N in SAP in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |