- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Early inspection lot generation on release of Prod...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member65

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

07-16-2020

3:21 AM

Purpose:

The Purpose of this blog to explain How to generate early inspection lot for EWM managed Materials through 1704 inspection type.

Business scenario:

Business want to have final inspection lot on release of Production order for final assembly or sub assembly, which are EWM managed Materials and business want to post stock into same inspection lot as QI Stock till final confirmation.

Solution in SAP:

As per the requirement, Business expecting to have early inspection lot. Since Materials are EWM managed, we should use 1704 inspection type for final goods inspections.

There is no ContolinspLot settings in 1704 inspection type to select early inspection lot option, which is available in 04 inspection type.Even though there is no such option in 1704 inspection type, same functionality can be achieved by using Presampling concept for Production order/ Process order.

1.1.SAP Notes

We must check whether following SAP Notes are implemented in system or Not. If Not, we must implement.

2610300 – Inspection document not created for batch subitems with zero quantity

2749295 – No inspection document update after changing process order

2783544 – Pre-Sampling in Production: Inspection Lot not created during Order Release.

1.2. Configuration

1.2.1 QBEXTP must be activated for pre-sampling in production by using transaction BF11

1.2.2 We must activate the Presampling field in IOT-4 (Inspection object type). This can be done through below IMG path.

IMG (transaction SPRO) > SCM Extended Warehouse Management >> Extended Warehouse Management >>> Cross-Process Settings >>>> Quality Management >>>>> Basics and integration >>>>>> Warehouse-Dependent Activation of Inspection Object Type.

The purpose of this setting is to activate the process to create the inspection document that is released before goods receipt posting. This applies only to inspection object type (IOT) 4 Q-Inspection Product/Batch Inbound Delivery.

If you activate this process, Inspection planning is always performed at activation of delivery.

This inspection process does not block the goods receipt for the internally produced goods in SAP Extended Warehouse Management. If the final decision is set for the inspection document, all further goods receipts for the same product/batch are posted to the stock category as configured for the logistical follow-up action.

1.3. Master data

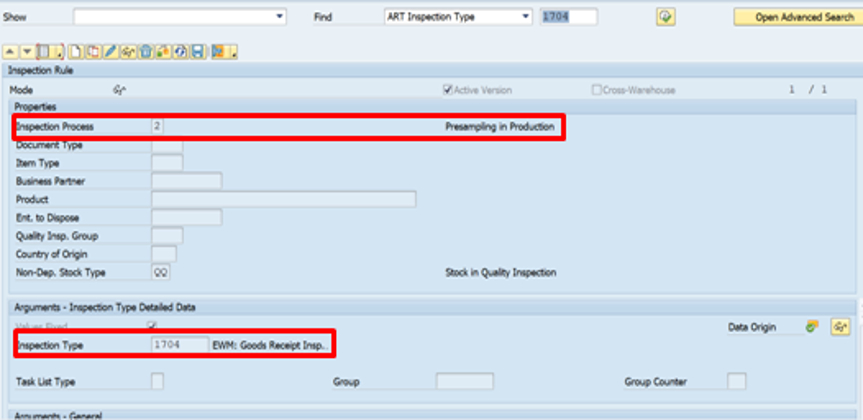

We must maintain the inspection rule for the warehouse where goods receipts happen for Production order/ Process order through T-Code /SCWM/QRSETUP. For this, we must select Inspection process as 2 i.e. Presampling in Production and 1704 as inspection type

By maintaining all above prerequisites, we can get the early inspection lot upon release of Production order/ Process order.

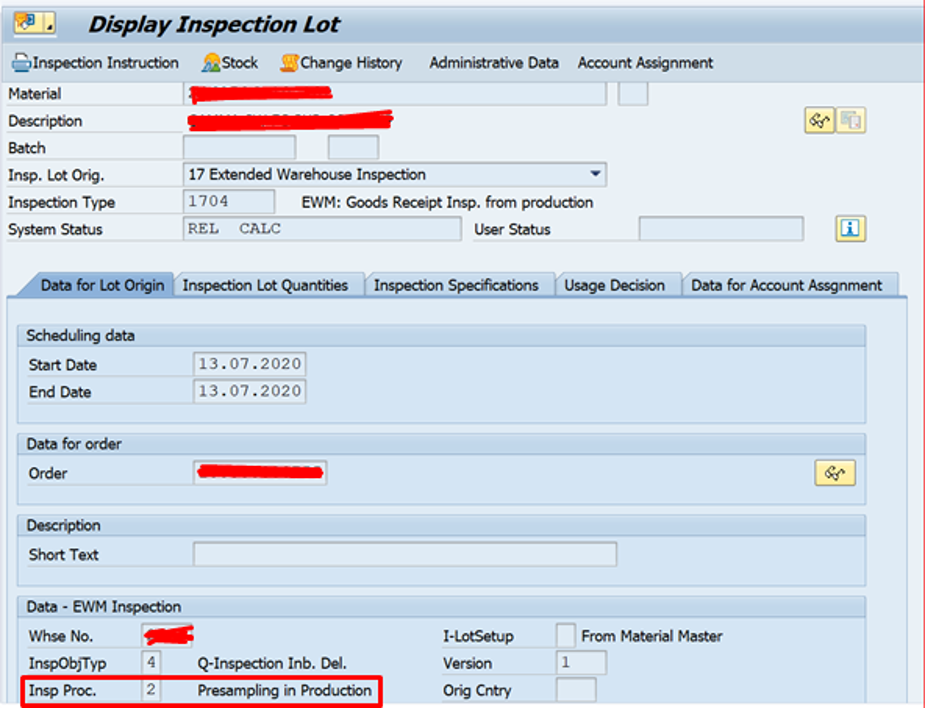

2.1. On release of Production order:

Manufacturing team create the Production order / Process order and release the order. Once Production order / Process order get released, System generate the inspection lot and same will reflect in QA32 work list.

If business assign the batch number (Either manually or automatic) during goods receipt, then there will not be any batch number in the inspection lot initailly, but batch number will get update once GR done for this production order.

If the business assigns the batch number (Either manually or automatic) during creation/ release of production order, same batch number will get update in the inspection lot, once it gets created.

Since there is no GR, system shows the actual qty as zero initially and there will not be any Material document associated with this inspection lot.

2.2 After Goods receipt from Production order:

After Goods receipt for the production order, Actual lot Qty get updated and there will be Material document/documents associated with this inspection lot.

Cons:

Conclusion:

By Maintaining the above-mentioned prerequisites, we can generate the early inspection lot successfully for EWM managed Materials through presampling concept.

The Purpose of this blog to explain How to generate early inspection lot for EWM managed Materials through 1704 inspection type.

Business scenario:

Business want to have final inspection lot on release of Production order for final assembly or sub assembly, which are EWM managed Materials and business want to post stock into same inspection lot as QI Stock till final confirmation.

Solution in SAP:

As per the requirement, Business expecting to have early inspection lot. Since Materials are EWM managed, we should use 1704 inspection type for final goods inspections.

There is no ContolinspLot settings in 1704 inspection type to select early inspection lot option, which is available in 04 inspection type.Even though there is no such option in 1704 inspection type, same functionality can be achieved by using Presampling concept for Production order/ Process order.

- Prerequisites:

1.1.SAP Notes

We must check whether following SAP Notes are implemented in system or Not. If Not, we must implement.

2610300 – Inspection document not created for batch subitems with zero quantity

2749295 – No inspection document update after changing process order

2783544 – Pre-Sampling in Production: Inspection Lot not created during Order Release.

1.2. Configuration

1.2.1 QBEXTP must be activated for pre-sampling in production by using transaction BF11

1.2.2 We must activate the Presampling field in IOT-4 (Inspection object type). This can be done through below IMG path.

IMG (transaction SPRO) > SCM Extended Warehouse Management >> Extended Warehouse Management >>> Cross-Process Settings >>>> Quality Management >>>>> Basics and integration >>>>>> Warehouse-Dependent Activation of Inspection Object Type.

The purpose of this setting is to activate the process to create the inspection document that is released before goods receipt posting. This applies only to inspection object type (IOT) 4 Q-Inspection Product/Batch Inbound Delivery.

If you activate this process, Inspection planning is always performed at activation of delivery.

This inspection process does not block the goods receipt for the internally produced goods in SAP Extended Warehouse Management. If the final decision is set for the inspection document, all further goods receipts for the same product/batch are posted to the stock category as configured for the logistical follow-up action.

1.3. Master data

We must maintain the inspection rule for the warehouse where goods receipts happen for Production order/ Process order through T-Code /SCWM/QRSETUP. For this, we must select Inspection process as 2 i.e. Presampling in Production and 1704 as inspection type

By maintaining all above prerequisites, we can get the early inspection lot upon release of Production order/ Process order.

- Generation of Early inspection lot:

2.1. On release of Production order:

Manufacturing team create the Production order / Process order and release the order. Once Production order / Process order get released, System generate the inspection lot and same will reflect in QA32 work list.

If business assign the batch number (Either manually or automatic) during goods receipt, then there will not be any batch number in the inspection lot initailly, but batch number will get update once GR done for this production order.

If the business assigns the batch number (Either manually or automatic) during creation/ release of production order, same batch number will get update in the inspection lot, once it gets created.

Since there is no GR, system shows the actual qty as zero initially and there will not be any Material document associated with this inspection lot.

2.2 After Goods receipt from Production order:

After Goods receipt for the production order, Actual lot Qty get updated and there will be Material document/documents associated with this inspection lot.

Cons:

- Sometimes, Presampling (QM-EWM) may not generate the early inspection lots in S/4 HANA 1809 even though all required configuration done, the reason for this is “In SMQ2, the queue QI* resp. QIPP* may not registered for processing. Hence the records will wait in queue and cannot be processed which is why system is not generating inspection lots, so we have to register the queue(s) accordingly”

- If the business user takes the UD before final confirmation of production order, system will generate the one more inspection lot for the same production order so we have to keep the inspection lot with out UD till final confirmation of production order to avoid multiple inspection lots for same Production order.

Conclusion:

By Maintaining the above-mentioned prerequisites, we can generate the early inspection lot successfully for EWM managed Materials through presampling concept.

- SAP Managed Tags:

- PLM Quality Management (QM)

13 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- Inspection type 03 result recording accept reject impact on next operation confirmation and GR. in Enterprise Resource Planning Q&A

- How to Create Outbound Delivery With order reference in SAP VL01N in Enterprise Resource Planning Blogs by Members

- Creation of Outbound Delivery using VL01N in SAP in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |