- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- PLANNED REPLENISHMENT IN EWM

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member67

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

06-13-2020

8:52 AM

Replenishment is defined as the movement of goods from the warehouse to the shipment locations. In SAP EWM, you can use predefined techniques for replenishment of storage bins. There are different replenishment control fields defined at the storage type level or storage bin level.

Planned Replenishment:

In planned replenishment the system calculates the replenishment in accordance with the defined minimum quantity and maximum quantity. Replenishment control is triggered when the stock is less than the minimum quantity. The system rounds down the replenishment quantity, in other words, the quantity of the warehouse task or the warehouse request, to a multiple of the minimum replenishment quantity.

Replenishment at storage type level or storage bin level

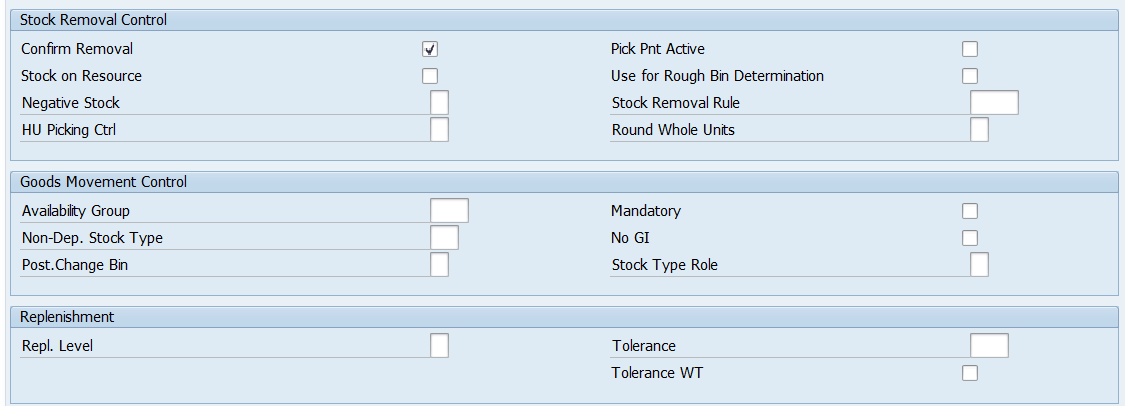

Define two storage types (NESB & NEST) and select replenishment level at storage bin level for fixed bins and storage type level respectively

Create bin (fixed bin) for the storage type NESB T.Code : /n/scwm/ls01

Define one storage type (NEST) and select replenishment at storage type level

select replenishment at storage type level

Create one storage bin for the storage type NEST (NEST-01-01-07) T.Code : /n/scwm/ls01

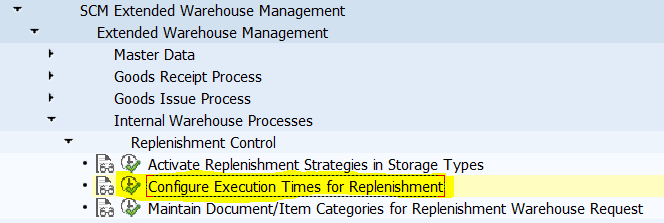

Now go to spro and activate replenishment strategies in storage types (NESB and NEST)

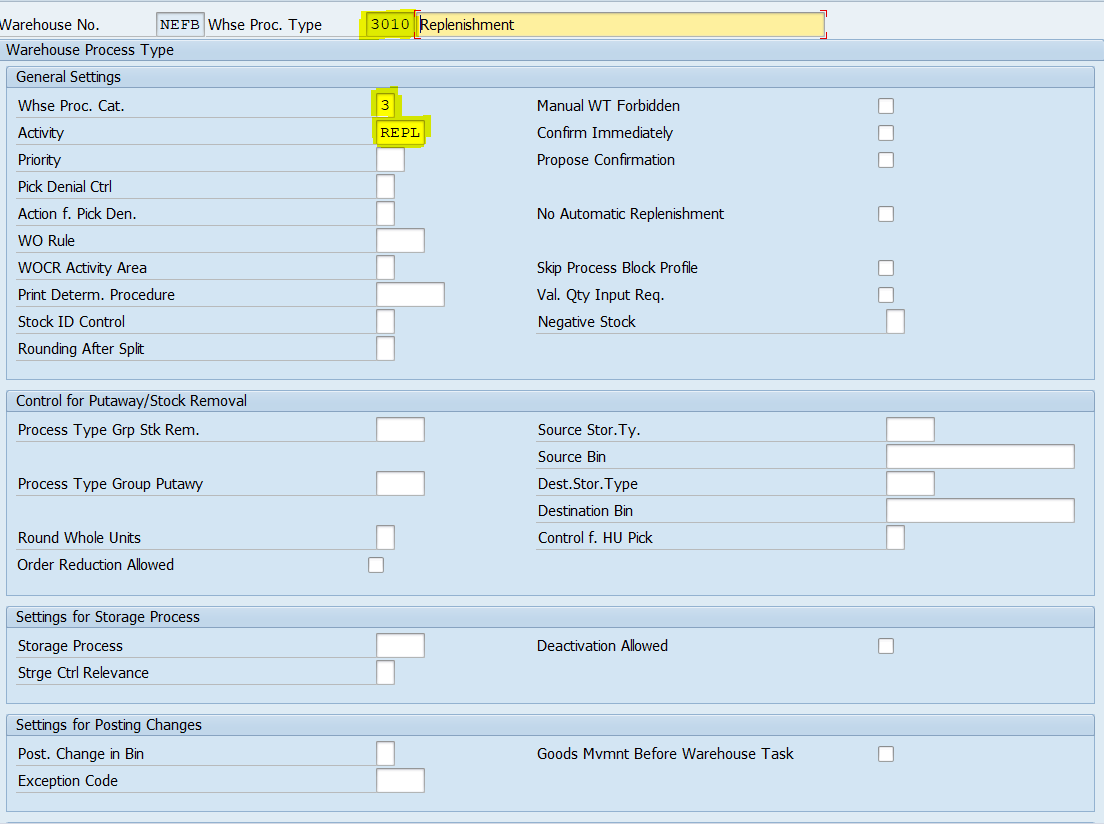

warehouse process type 3010 is used for replenishment

Determine warehouse process type

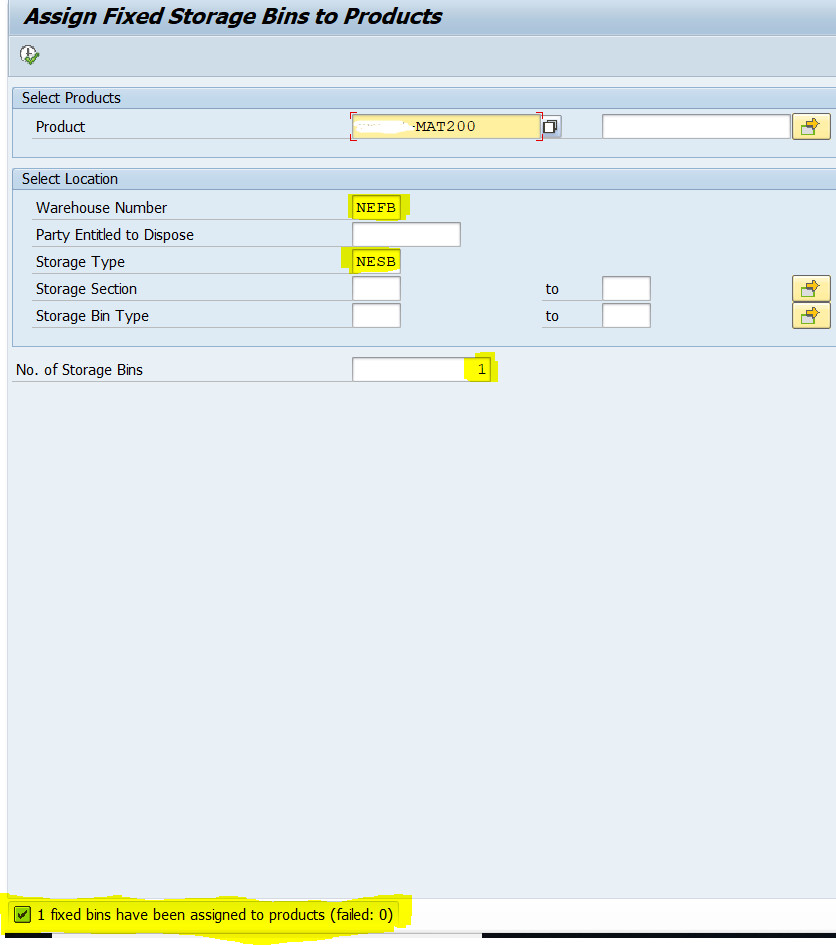

Go to T.Code: /N/SCWM/FBINASN assign fixed bins for replenishment at storage bin level

Go to T.Code: /N/SCWM/BINMAT and maintain the the fixed bin

NESB-FIXEDBIN200 is maintained for storage bin and execute it

here maintain minimum and maximum quantity of products for storage bins

Now go to T.Code: /n/scwm/mat1 create and add storage type NESB ,,manintain minimum replenisment quantity

now go to spro and maintain picking strategies for replenishment

Define stock removal control indicator

Go to T.Code : /n/scwm/repl and start planned replenishment

enter details like warehouse number, storage type and product execute it

replenishment run started and warehouse task 103800 is created

now go to warehouse monitor and confirm the warehouse task 103800

fixed bin NESB-FIXEDBIN200 is replenished with 28 products

Replenishment at storage type (NEST)

Go to T.Code: /n/scwm/mat1 add storage type NEST in the storage type view enter maximum bins minimum replenishment quantity , minimum quantities and maximum quantities

now lets execute replenishment at storage type level

maintain minimum quantity maximum quantity and minimum replenishment quantity

Go to T.Code : /n/scwm/repl and start planned replenishment

go to warehouse monitor and confirm the warehouse tasks

confirm the warehouse tasks 103801 and 103802

storage bin NEST-01-01-07 is replenished with 30 quantities

conclusion :

Replenishment is an internal process and is used to fill up a picking area in accordance with the demand for products.normally warehouses have primary picking zones and buffer zones to manage their inventory. These primary zones are maintained nearby to door areas to use as picking area and maintain with predefined maximum, minimum stock quantity levels. whenever any product stock level falls below minimum stock level, a replenishment WT executes to fill stock up to maximum level.

There are two levels to control replenishment process, one is at storage type level and other one is storage bin level. It means required material quantity can either be determined for the storage type as a whole or, in the case of a fixed bin scenario, for each individual fixed bin in the primary area.

Planned Replenishment:

In planned replenishment the system calculates the replenishment in accordance with the defined minimum quantity and maximum quantity. Replenishment control is triggered when the stock is less than the minimum quantity. The system rounds down the replenishment quantity, in other words, the quantity of the warehouse task or the warehouse request, to a multiple of the minimum replenishment quantity.

Replenishment at storage type level or storage bin level

Define two storage types (NESB & NEST) and select replenishment level at storage bin level for fixed bins and storage type level respectively

select replenishment at storage type level

select replenishment at storage type level

Create bin (fixed bin) for the storage type NESB T.Code : /n/scwm/ls01

Define one storage type (NEST) and select replenishment at storage type level

select replenishment at storage type level

Create one storage bin for the storage type NEST (NEST-01-01-07) T.Code : /n/scwm/ls01

Now go to spro and activate replenishment strategies in storage types (NESB and NEST)

warehouse process type 3010 is used for replenishment

Determine warehouse process type

Go to T.Code: /N/SCWM/FBINASN assign fixed bins for replenishment at storage bin level

one fixed bins is assigned to products

one fixed bins is assigned to products

Go to T.Code: /N/SCWM/BINMAT and maintain the the fixed bin

NESB-FIXEDBIN200 is maintained for storage bin and execute it

here maintain minimum and maximum quantity of products for storage bins

Now go to T.Code: /n/scwm/mat1 create and add storage type NESB ,,manintain minimum replenisment quantity

now go to spro and maintain picking strategies for replenishment

Define stock removal control indicator

Go to T.Code : /n/scwm/repl and start planned replenishment

enter details like warehouse number, storage type and product execute it

replenishment run started and warehouse task 103800 is created

now go to warehouse monitor and confirm the warehouse task 103800

fixed bin NESB-FIXEDBIN200 is replenished with 28 products

Replenishment at storage type (NEST)

Go to T.Code: /n/scwm/mat1 add storage type NEST in the storage type view enter maximum bins minimum replenishment quantity , minimum quantities and maximum quantities

now lets execute replenishment at storage type level

maintain minimum quantity maximum quantity and minimum replenishment quantity

Go to T.Code : /n/scwm/repl and start planned replenishment

enter details like warehouse number, storage type and product execute it

go to warehouse monitor and confirm the warehouse tasks

confirm the warehouse tasks 103801 and 103802

storage bin NEST-01-01-07 is replenished with 30 quantities

conclusion :

Replenishment is an internal process and is used to fill up a picking area in accordance with the demand for products.normally warehouses have primary picking zones and buffer zones to manage their inventory. These primary zones are maintained nearby to door areas to use as picking area and maintain with predefined maximum, minimum stock quantity levels. whenever any product stock level falls below minimum stock level, a replenishment WT executes to fill stock up to maximum level.

There are two levels to control replenishment process, one is at storage type level and other one is storage bin level. It means required material quantity can either be determined for the storage type as a whole or, in the case of a fixed bin scenario, for each individual fixed bin in the primary area.

- SAP Managed Tags:

- EWM - Goods Movement

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- What's new with Collaborative Maintenance? in Supply Chain Management Blogs by SAP

- SAP Intelligent Clinical Supply Management goes CTS Europe 2024 – our key insights in Supply Chain Management Blogs by SAP

- “Mind the Gap” – Improves ROI, Cost & Margin by Merging Planning Processes in Supply Chain Management Blogs by SAP

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

- 5 Reasons why Planners Should Consider the RISE with SAP Advanced Supply Chain Planning Package in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |