- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Combined storage control (POSC+LOSC) for inbound p...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

POSC during inbound process is used to map complex putaway processes to determine the relevant process steps required and the sequence of the process steps. this lets you track the overall process while having visibility to the execution of the individual process steps.

In the customizing for the storage control, you can flexibly define the necessary process steps to fulfill an overall process. you can see that the following process steps are defined as part of the POSC for the putaway process for Handling unit. (HU)

1. Unload the HU at the door

2. Move the HU to staging area

3. Deconsolidation of mixed products so that they can be put away separately into the warehouse

4. Valve Added Services (VAS) activities like labeling ,oiling etc

5. Put away the HU's to the final bin

Layout Oriented Storage Control (LOSC)

Business process sometimes needs to use an interim storage type and bin, when transferring stock from one area of the warehouse to another to check wieght volume etc, you can manage this requirement in EWM using the LOSC.

Combined Storage Control for Inbound Processing

Both the POSC and the LOSC are used together, the POSC is always checked first during execution of the storage control. An example of a warehouse storage process that includes both the POSC and LOSC could include the following process steps:

1. Unloading the HU's at the door (POSC)

2. Deconsolidation of the HU's at the work center (POSC)

3. Value Added Services (VAS) at VAS work center (POSC)

4. Placing the goods at one interim storage location for wieght check (LOSC)

5. Lifting the goods to mezzanine floor (LOSC)

6. Putting away the HUs into the high rack bin (POSC)

Unload takes place at door (storage type), goods reciept takes place at GR staging area (storage type), Deconsolidation takes place at Deconsolidation work center (storage type), VAS takes place at VAS work center (storage type), placing the goods at ground floor (storage type), lifting the HU’s to mezzanine floor (storage type) and final putaway of HU’s in to final storage type.

The configuration steps for POSC and LOSC are as follows

1.Define door storage type and create storage bin for door

2.Define staging area (storage type) and one staging area bin

3. Define work center (storage type) , work center bin , work center layout and work center

Work center as storage type with storage type role ‘E’

Standard work center layout ‘DKMK’ is used

Work center is defined with external step of deconsolidation is assigned along storage type NFWC defined earlier for work center and external step for deconsolidation N002

Now go to T.Code: /N/SCWM/TWORKST and maintain storage bin of work center in work center

4.Define VAS work center, one bin for VAS work center, VAS work center layout create one order for VAS for products that are relevant to VAS activity

VAS work center layout VAS1 is used

VAS work center is maintained with VAS1 work center layout and VAS storage type along with VAS external step N003

Now go to T.Code: /N/SCWM/TWORKST and maintain storage bin of VAS in VAS work center

Configuration setup for creation of VAS order

VAS order is required for line items that are relevant to VAS activities

Now go to T.Code (/N/SCWM/PACKSPEC) create packaging specification for items that are relevant to VAS activities here (MAT100 and MAT200)

Maintain packaging material and work step

Maintain external step NVAS in the warehouse tab

Maintain condition technique and activate packaging specification 10000071

Similarly maintain another packaging specification for second item MAT200, maintain condition technique and activate packaging specification 10000108

5. Define ground floor (storage type) and one storage bin

6.Define mezzanine floor (storage type) and one storage bin

7. Define POSC

Define external storage process steps

Define storage process

Assign storage process to external storage process steps

Define POSC to maintain source and destination storage types and storage bins

8. Define LOSC

Maintain source and destination for LOSC setup

9.Define warehouse process type maintian source storage type and storage bin for unloading maintian storage process N001

This completes the configuration steps for combined storage process.

Business process

You order for certains goods from vendor by creating purchase order in S/4 HANA system for two different stocks and send it vendor. vendor sends the Advance shipping notification (ASN) by with prior information that he (vendor) is sending two stocks in a single carton box with relevant VAS activities to be performed based on ASN .you create an inbound delivery for two line items packed into a single carton box. In EWM stocks needs to be unloaded ,deconsolidated into individual handling units or carton box and perform VAS activity , place it to interim storage type to Identify wieght , volume. then lift it to mezzanine floor and finally putway individual carton boxes into respective storage types and storage bin.

TEST CASE ON COMBINED STORAGE CONTROL (POSC+LOSC)

Create one inbound delivery with reference to purchase order number (4500000134)

inbound delivery for two-line items of 1 quantity each is created

Pack the two line items into one single packaging material (carton box) 1000001001

Pack the two line items into one single packaging material (carton box) 1000001001

One inbound delivery is created and distributed into Embedded EWM

Now, go to (T.Code : /n/scwm/prdi) and enter the ERP document number (180000213) and execute it

Go to item level and check for order for VAS has been generated for both items that are relevant to VAS activity, if not maintain VAS order manually

VAS order created for line item 10 (6072)

VAS order created for line item 20 (6073)

create warehouse task for the warehouse request 2816

One warehouse task is created to move the HU (1000001001) from door to GR staging area. create save and confirm the warehouse task

Go to warehouse monitor (/N/SCWM/MON) enter the inbound delivery document number and check the warehouse task confirmed

Warehouse task 102398 to move the HU from door to staging area is confirmed, along with the confirmed warehouse task two new warehouse tasks (102399 & 102400) is created with status waiting to move the products from GR staging area to final destination bin and one more warehouse task(102401) with status open to move the HU from GR staging area to deconsolidation work center.

Confirm the warehouse task 102401 now the HU is available in deconsolidation work center now, go to T.Code ( /N/SCWM/DCONS)

enter warehouse number, work center and warehouse request and execute it, deconsolidate the items in HU 1000001001 into two new HU’s

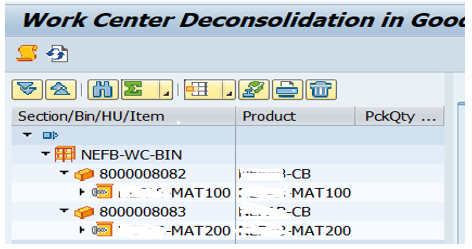

Deconsolidate the items in the HU 1000001001 into two separate HU’s 8000008082 and 8000008083

Two-line items are deconsolidated into two different HU’s 8000008082 and 8000008083

Close the HU’s individually to complete the deconsolidation process.

After closing the HU’s two new warehouse tasks (102402 and 102403) are created to move the new HU’s from work center to VAS work center

Go to warehouse monitor and confirm the open warehouse tasks to move the HU’s Two new subsequent warehouse tasks (102402 & 102403)are created to move the HU’s from deconsolidation work center to VAS work center.

Now go to T.Code ( /n/scwm/vasexec) and enter the warehouse number, VAS work center and warehouse request number and execute it

Click on VAS tree and complete the VAS step by clicking on start and end w/o variances for each item that are relevant for VAS

After completing the VAS activity close the individual HU’s to complete the VAS step

After closing the HU’s two new subsequent warehouse tasks (102404 and 102405) are created to move the HU’s from VAS work center to one interim storage type (ground floor)

Go to warehouse monitor and confirm two new warehouse tasks with status open to move the HU’s from VAS work center to one interim storage type (ground floor)

Once you confirm the open warehouse tasks two new warehouse tasks (102406 and 102407) is created with status open to move the HU’s from ground floor to interim storage type (ground floor)

After confirming the warehouse tasks (102406 and 102407) two new warehouse tasks are created to move the HU ‘s from first floor (mezzanine) to final storage type (storage bins)

Confirm the open warehouse tasks to move individual HU’s from mezzanine floor bin to final storage bins

CONCLUSION

Combined storage process involves POSC and LOSC processes which are used in complex multistep movements inside the warehouse due to restrictions in warehouse layout. Where POSC involves warehouse activities like unload, deconsolidate, VAS, putaway and LOSC involves identifying and lifting of goods to mezzanine floors. EWM supports to track and execute these multistep movements.

- SAP Managed Tags:

- EWM - Delivery Processing

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

BI

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Change History

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Monitor

1 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

FINANCE

1 -

Freight Settlement

1 -

FSM

1 -

FUB_Strategy

1 -

FUBR

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Material Master changes

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PowerBI

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

SAC

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP FSM

1 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SAPTM

1 -

SD (Sales and Distribution)

1 -

Shotcut_Scenario

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

- SAP S/4HANA TM Load Optimization – Tricks and Trips for different use-cases – Prioritized truckloads in Supply Chain Management Blogs by SAP

- SAP S/4HANA TM Load Optimization – Tricks and Trips for different use-cases – Dead-stack Loading in Supply Chain Management Blogs by SAP

- S/4 TM Load Optimization - Tricks and Trips for different use-cases - Minimize Product Spread in Supply Chain Management Blogs by SAP

- One Step Closer to Seamless Maintenance Strategy and Execution Integration with SAP Asset Performance Management 2312 Plus Q4 Highlights in Supply Chain Management Blogs by SAP

- How to Make Your Clinical Distribution More Efficient in Supply Chain Management Blogs by SAP

| User | Count |

|---|---|

| 4 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |