- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- SAP Asset Intelligence Network - Master Data (Part...

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

pardhreddyc

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-26-2020

5:02 PM

Hello Everyone,

Greetings!

I hope everyone is aware of the recent release 2005 version on SAP Intelligence Asset Management.

This blog will brief about a few of the Master Data available in the AIN network and new search feature of the equipment called UID(Unique Identification Number) as well. The UID has come with the 2005 version.

First, let us talk about Model Master.

Model:

A Model is a representation by the manufacturer for existing technical object products. In real-world model is an illustration of equipment.

In AIN model can be created for Equipment and for System as well. One should understand that,

If Model is being created for Equipment, it can be tracked using

If the Model is being created for System, we can not track the SYSTEM using any o the tracking criteria such as Serial number/Batch number. (No option in AIN)

Equipment:

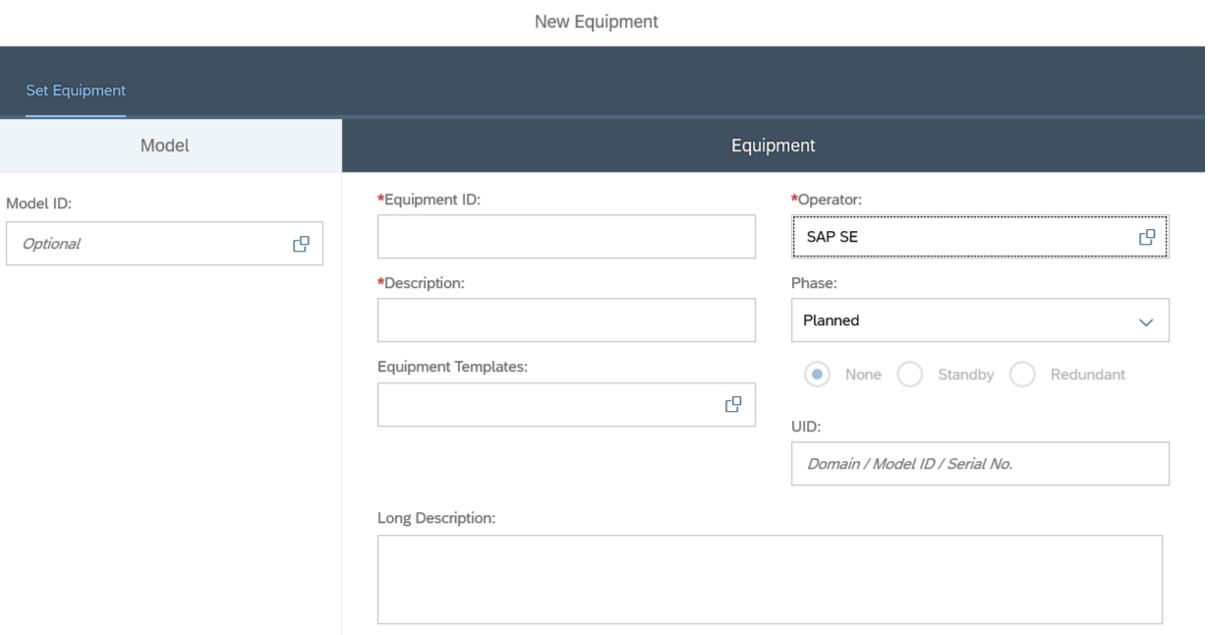

It is a physical instance of MODEL and an operator can maintain equipment Installation Information, Installation location by using geographical coordinates and relevant documents viz., SOPs, OEM Guidelines, Maintenance Procedures, Technical drawings, etc...

The new filed which has introduced in the 2005 version is UID-Unique ID number and should be maintained as a combination of Domain/Model ID/Serial Number, which has a field length of 72 characters. This UID could help to identify the equipment in any system, however, note that the UID field is not mandatory.

While creating an Equipment, by default the 'Company" is assigned as an operator.

For example, I have considered the external number assignment for equipment to track based on business lines

here, I considered UID as per my pump designation based on MODEL specifications for example,

or else we can directly input the UID from nameplate details in the given format as "Domain/Model ID/Serial Number"

Equipment Phase/System Status can be identified by using a few icons,

One should understand the logic of phase changes. once we move planned Phase to Operational (Not/Partial/Fully) we can not revoke,

however, we can move back & forth from

but, we can not revoke the phase from

Note: To update the equipment phases such as Dispose/Retire/Sold, it should be dismantled from the existing assigned location, and to attain sold phase, it should be Published with an assignment of Model.

Phases that could be maintained for Equipment:

I hope this information could help you all to understand the features of SAP IAM-AIN...

--

Yours faithfully,

Pardhasaradhi Reddy.C

Greetings!

I hope everyone is aware of the recent release 2005 version on SAP Intelligence Asset Management.

This blog will brief about a few of the Master Data available in the AIN network and new search feature of the equipment called UID(Unique Identification Number) as well. The UID has come with the 2005 version.

First, let us talk about Model Master.

Model:

A Model is a representation by the manufacturer for existing technical object products. In real-world model is an illustration of equipment.

In AIN model can be created for Equipment and for System as well. One should understand that,

If Model is being created for Equipment, it can be tracked using

- Serial Number at Model Level

- Serial Number at Manufacturer Level

- Batch Number at Batch Level

If the Model is being created for System, we can not track the SYSTEM using any o the tracking criteria such as Serial number/Batch number. (No option in AIN)

Equipment:

It is a physical instance of MODEL and an operator can maintain equipment Installation Information, Installation location by using geographical coordinates and relevant documents viz., SOPs, OEM Guidelines, Maintenance Procedures, Technical drawings, etc...

The new filed which has introduced in the 2005 version is UID-Unique ID number and should be maintained as a combination of Domain/Model ID/Serial Number, which has a field length of 72 characters. This UID could help to identify the equipment in any system, however, note that the UID field is not mandatory.

While creating an Equipment, by default the 'Company" is assigned as an operator.

For example, I have considered the external number assignment for equipment to track based on business lines

here, I considered UID as per my pump designation based on MODEL specifications for example,

or else we can directly input the UID from nameplate details in the given format as "Domain/Model ID/Serial Number"

Equipment Phase/System Status can be identified by using a few icons,

One should understand the logic of phase changes. once we move planned Phase to Operational (Not/Partial/Fully) we can not revoke,

however, we can move back & forth from

- Not operational<=>Partial operational<=>Fully operational

- Operational<=>Dispose

but, we can not revoke the phase from

- Dispose=>Retire

- Retire=>Sold

Note: To update the equipment phases such as Dispose/Retire/Sold, it should be dismantled from the existing assigned location, and to attain sold phase, it should be Published with an assignment of Model.

Phases that could be maintained for Equipment:

- Planned/Current Phase: Which can be maintained using the “Manage Phase” dialog

- Next Phase: With which the maintenance department can plan upcoming phase changes, for an example, when the EQUIPMENT was under “Not Operational” due to some maintenance work, so the reliability engineer/manager would like to update the status post completion of repair work in the "next phase" as a “Partial Operational” till the execution of the trail run and then followed by "Fully Operational” phase post successful completion of the trail run or validation of load factors.

I hope this information could help you all to understand the features of SAP IAM-AIN...

--

Yours faithfully,

Pardhasaradhi Reddy.C

2 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- SAP Business Network for Logistics 2404 Release – What’s New? in Supply Chain Management Blogs by SAP

- SAP Intelligent Clinical Supply Management goes CTS Europe 2024 – our key insights in Supply Chain Management Blogs by SAP

- RISE with SAP Advanced Logistics Package in Supply Chain Management Blogs by SAP

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

- 5 Reasons why Planners Should Consider the RISE with SAP Advanced Supply Chain Planning Package in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 4 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |