- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Embedded EWM Opportunistic Cross-Docking

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member67

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-22-2020

11:19 PM

Purpose -

In this Post we will discuss about Opportunistic Cross-docking and how does it work in Embedded EWM by running a Test Scenario. We will also discuss the Master data & Configuration setting needed to be done in Opportunistic Cross-docking.

First we need to understand what is Cross-docking ?

Cross-docking is a process, which uses the processing of goods in a warehouse by using incoming stock directly for outbound processing without storing in warehouse.

EWM triggered opportunistic cross-docking is a process that works entirely within a single EWM instances and does not need support from other application or systems. During creation of warehouse tasks for putaway or picking ,stock determines from docking areas (staging).

This process is driven by two ways:

1.INBOUND DRIVEN: During putawy warehouse task creation, system checks whether any ODO items exits, that matches with the task items regarding quantity and expiration date. Then system creates cross-docking WT instead of creating putaway WT.

2.OUTBOUND DRIVEN: During picking WT creation , system checks to see if stock in the goods receipt staging area exists that is more adequate for the ODO item than stock from within the warehouse.

NOTE: It is mandatory to activate the BADI’s to use this functionality.

CONFIGURATION TO BE DONE:

1.1 BADI: Activation and Adjust Inbound-Triggered Cross docking Process :

PATH: Spro—SCM EWM—EWM—BADI for EWM—Cross process settings—Cross-docking—Opportunistic Cross docking—EWM-Triggered Cross Docking Inbound—Badi: Activation and Adjustment Inbound-Triggered Cross Docking Process

1.2 BADI: Activation and Adjust Outbound-Triggered Cross docking Process :

PATH: Spro—SCM EWM—EWM—BADI for EWM—Cross process settings—Cross-docking—Opportunistic Cross docking—EWM-Triggered Cross Docking Outbound—Badi: Activation and Adjustment Outbound-Triggered Cross Docking Process

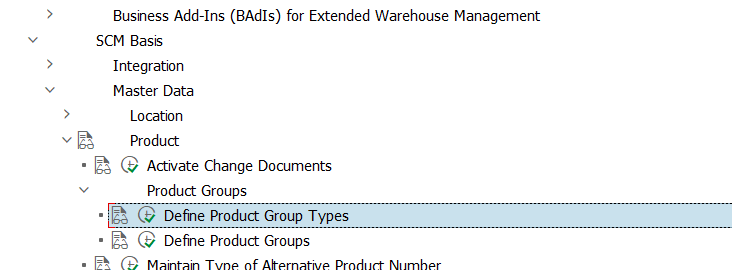

1.3 Define Product Group Types:

PATH: Spro—Img---SCM EWM—SCM Basis –Master Data—Product—Product Groups—Define Product Group types

1.4 Define Product Group:

PATH: Spro—Img---SCM EWM—SCM Basis –Master Data—Product— Product Groups-- Define Product Group

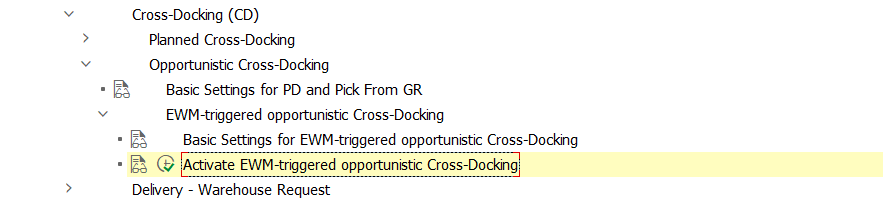

1.5 Activate EWM-Triggered opportunistic Cross-Docking:

PATH: Spro—Img—SCM EWM—EWM—Cross-process settings—Cross-Docking—Opportunistic Cross-docking---EWM triggered opportunistic Cross-Docking—Activate EWM-triggered opportunistic Cross-Docking

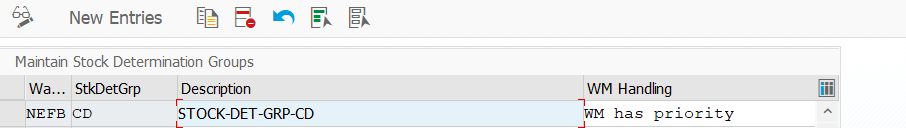

1.6 Maintain Stock Determination groups:

PATH: Spro—Img---SCM EWM—EWM—Cross-process settings—Stock Determination---Maintain Stock Determination groups

1.7 Configure Stock Determination:

PATH: Spro—Img---SCM EWM—EWM—Cross-process settings—Stock Determination---Maintain Stock Determination groups

1.8 Specify Storage Type Search Sequence:

PATH: Spro—Img---SCM EWM—EWM—Goods Issue Process—Specify Storage type search Sequence.

1.9 Master Data:

Here maintain Product group type, product group and stock determination in product master data.

1.9.1 Maintain Product group type and product group:

TRANSACTION: /N/SAPAPO/MAT1

1.9.2 Maintain Stock determination group:

TRANSACTION:/N/SCWM/MAT1

TEST CASE

Here we run a test of Opportunistic cross-docking for Outbound Process.

Step-1

Transaction: /scwm/prdo

Maintain Outbound delivery order:

Confirm Warehouse Task as shown below-

Here the system Checks the attributes of the product which is to be cross-docked and already is in GR-staging area.

Step-2

Create warehouse task against outbound delivery order:

Here we can see product is cross docked and proposed GR staging as source for outbound delivery order.

In Warehouse Task the PDI & PDO reference document can be found.

RESULT:

Above Test case demonstrate the EWM triggered cross docking scenario during outbound process. Here EWM checks the open WT (outbound) for the material (MAT-100) which is present in GR-zone. EWM pick the same material from the GR-zone and put the material in Picking GI-zone. In the background EWM also creates a cross-dock document.

In this Post we will discuss about Opportunistic Cross-docking and how does it work in Embedded EWM by running a Test Scenario. We will also discuss the Master data & Configuration setting needed to be done in Opportunistic Cross-docking.

First we need to understand what is Cross-docking ?

Cross-docking is a process, which uses the processing of goods in a warehouse by using incoming stock directly for outbound processing without storing in warehouse.

EWM triggered opportunistic cross-docking is a process that works entirely within a single EWM instances and does not need support from other application or systems. During creation of warehouse tasks for putaway or picking ,stock determines from docking areas (staging).

This process is driven by two ways:

1.INBOUND DRIVEN: During putawy warehouse task creation, system checks whether any ODO items exits, that matches with the task items regarding quantity and expiration date. Then system creates cross-docking WT instead of creating putaway WT.

2.OUTBOUND DRIVEN: During picking WT creation , system checks to see if stock in the goods receipt staging area exists that is more adequate for the ODO item than stock from within the warehouse.

NOTE: It is mandatory to activate the BADI’s to use this functionality.

CONFIGURATION TO BE DONE:

1.1 BADI: Activation and Adjust Inbound-Triggered Cross docking Process :

PATH: Spro—SCM EWM—EWM—BADI for EWM—Cross process settings—Cross-docking—Opportunistic Cross docking—EWM-Triggered Cross Docking Inbound—Badi: Activation and Adjustment Inbound-Triggered Cross Docking Process

1.2 BADI: Activation and Adjust Outbound-Triggered Cross docking Process :

PATH: Spro—SCM EWM—EWM—BADI for EWM—Cross process settings—Cross-docking—Opportunistic Cross docking—EWM-Triggered Cross Docking Outbound—Badi: Activation and Adjustment Outbound-Triggered Cross Docking Process

- NOTE: Product group types and product groups serve to group products of the same kind. You define a product group type for the criterion with which the product groups are to be formed.

1.3 Define Product Group Types:

PATH: Spro—Img---SCM EWM—SCM Basis –Master Data—Product—Product Groups—Define Product Group types

1.4 Define Product Group:

PATH: Spro—Img---SCM EWM—SCM Basis –Master Data—Product— Product Groups-- Define Product Group

1.5 Activate EWM-Triggered opportunistic Cross-Docking:

- Here we Assign a product group type to a warehouse no to activate EWM triggered opportunistic cross docking for the inbound process or for outbound process.

PATH: Spro—Img—SCM EWM—EWM—Cross-process settings—Cross-Docking—Opportunistic Cross-docking---EWM triggered opportunistic Cross-Docking—Activate EWM-triggered opportunistic Cross-Docking

1.6 Maintain Stock Determination groups:

- Here we maintain Stock determination for each warehouse no and assign them to product in product master. We assign it because if we want to determine a valid stock of product , then system performs a stock determination.

PATH: Spro—Img---SCM EWM—EWM—Cross-process settings—Stock Determination---Maintain Stock Determination groups

1.7 Configure Stock Determination:

PATH: Spro—Img---SCM EWM—EWM—Cross-process settings—Stock Determination---Maintain Stock Determination groups

- We need to maintain it because during warehouse task creation with requested stock attributes, the system includes the stocks that posses the permitted attributes in the stock determination.

1.8 Specify Storage Type Search Sequence:

PATH: Spro—Img---SCM EWM—EWM—Goods Issue Process—Specify Storage type search Sequence.

- We need to maintain GR staging area in stock removal storage type search sequence to determine cross-docking stock.

1.9 Master Data:

Here maintain Product group type, product group and stock determination in product master data.

1.9.1 Maintain Product group type and product group:

TRANSACTION: /N/SAPAPO/MAT1

- Maintain product group type and product group under properties tab at global level.

1.9.2 Maintain Stock determination group:

- Maintain stock determination group for product under stock removal control area at warehouse level.

TRANSACTION:/N/SCWM/MAT1

TEST CASE

Here we run a test of Opportunistic cross-docking for Outbound Process.

Step-1

Transaction: /scwm/prdo

Maintain Outbound delivery order:

Confirm Warehouse Task as shown below-

Here the system Checks the attributes of the product which is to be cross-docked and already is in GR-staging area.

- Same product

- Batch

- Quantity including stock separation characteristics like party entitled to dispose or the Sales order stock.

Step-2

Create warehouse task against outbound delivery order:

Here we can see product is cross docked and proposed GR staging as source for outbound delivery order.

In Warehouse Task the PDI & PDO reference document can be found.

RESULT:

Above Test case demonstrate the EWM triggered cross docking scenario during outbound process. Here EWM checks the open WT (outbound) for the material (MAT-100) which is present in GR-zone. EWM pick the same material from the GR-zone and put the material in Picking GI-zone. In the background EWM also creates a cross-dock document.

- SAP Managed Tags:

- SAP Extended Warehouse Management,

- EWM - Delivery Processing,

- EWM - Goods Movement,

- EWM - Master Data

7 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- What's the Cross-docking process effect on inventory valuation at controlling and accounting? in Supply Chain Management Q&A

- Error in RFUI on confirmation of Crossdocking warehouse task in EWM in Supply Chain Management Q&A

- Warehouse Management System in Supply Chain Management Blogs by Members

- EWM - Opportunistic crossdocking with Wave in Supply Chain Management Q&A

- Problem with outbound-driven opportunistic cross-docking in Supply Chain Management Q&A

Top kudoed authors

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |