- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- SAP S/4HANA Product Allocation Process

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Ruthvik

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

04-03-2020

2:16 PM

Dear SAP Friends,

Welcome to another interesting topic, Product Allocation

In this blog, I would like to share process steps involved in Product Allocation

If you would like to know first what exactly product allocation is, Hear is a high-level overview

Competitive order processing that aims to deliver the required quantity to the customer at the requested time demands precise planning and control mechanisms. Unpredictable problems, such as breakdowns in production or increased demand, can lead to critical situations in order processing and must be brought under control before they arise.

Product allocations provide this sort of control and enable your company to avoid these critical situations in demand and procurement. Equal allocation of products in short supply must be possible, as must speedy reaction to bottlenecks and changing market situations.

Depending on the period, you can allocate products for specific customers or regions. Using product allocations in situations in which a product is in short supply, you can avoid allocating the entire available quantity to the first customer, which either delays the confirmation of subsequent sales orders or makes confirmation impossible.

Source SAP Library:- Product Allocation

Now let’s see how to activate Product Allocation

The system I used to execute PAL is S/4HANA 1909 FPS01

Once Activated PAL in SPRO rest everything needs to be done in Fiori there is no GUI transactions for PAL

Below are 5 Applications required to execute PAL

Click Create

Maintain Required Fields as per business requirement

Based on the requirement we can select both Sales orders and Stock Transfer Orders as well

Once General Information has maintained Click Characteristics and maintain

We can select characteristics based on the business requirement from the available list, if the available list is not compatible with the business we can add more characteristics via “Manage Characteristic Catalogs” app

Once maintained General Information & Characteristics save

Click on Go to see previously created Allocation

Click on edit and then Add option to add characteristics which we have selected previously

In the Selection Range, we can select as per requirement

In allocation planning Data maintain Characteristic values and planning figures

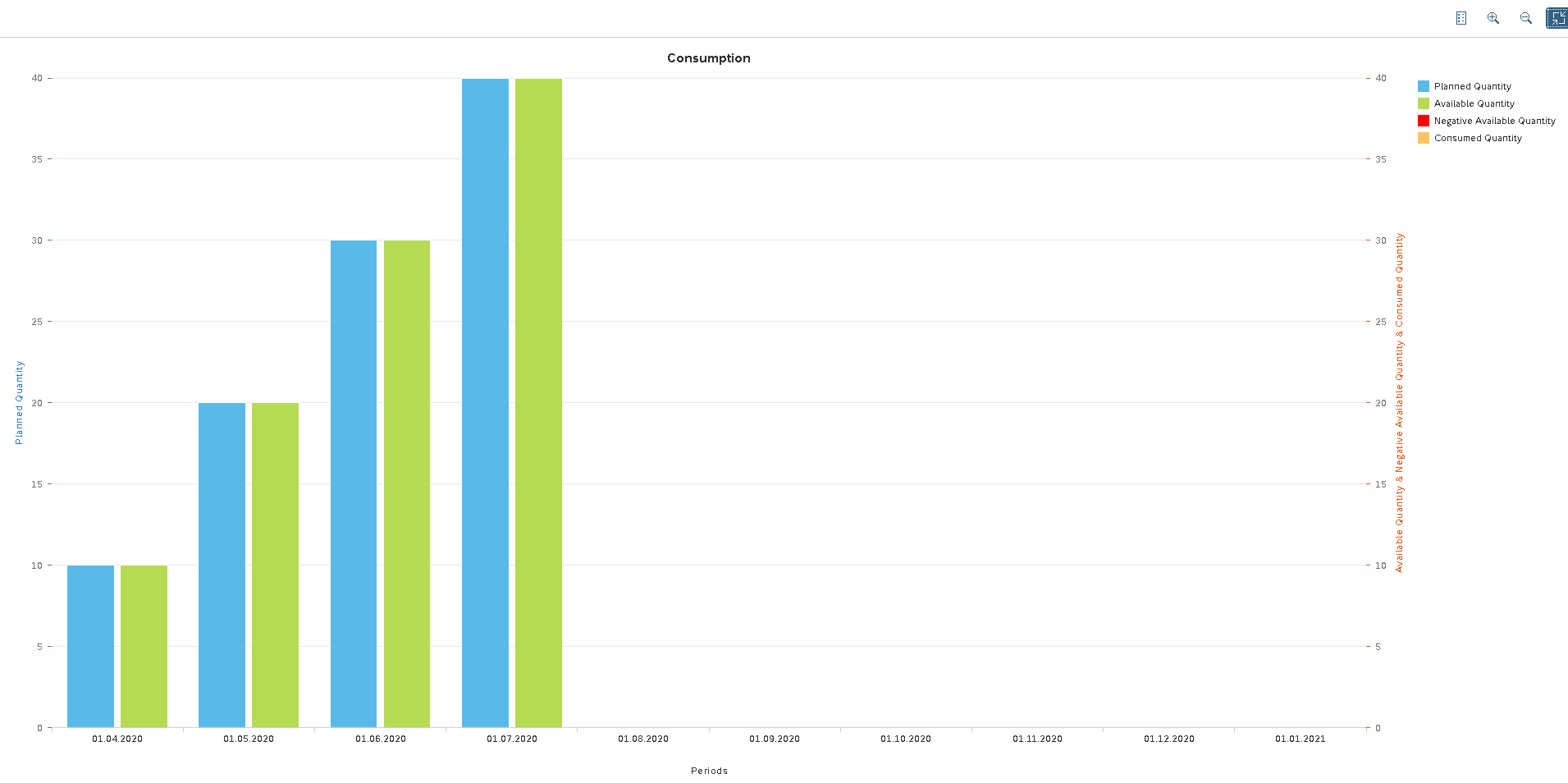

The graph will be generated as per the values maintained in planning its Planned and available Quantity

Once all data maintained Save

Click on Create

In General, Information Tab maintain Required Fields

Backward consumption & Forward Consumption data need to be given

Its how many months system need to consider for allocating, System first goes backwards if no quantity available then system checks in forward

From 1909 onward Capacity Sequence groups have been introduced

Sales sequence groups are checked against product allocation before the product availability check. Capacity sequence groups are considered after the product availability check.

Open Sales sequence groups and from the drop-down select the Allocation Object which we created in 1st step

The time period can be given as per requirement

Once maintained all values click apply and save

From Name itself, we can understand what needs to be done ?

From Name itself, we can understand what needs to be done ?

We need to assign Material to Allocation Object

Note:- Unit of measure which we given initially while creation allocation object and materials which we add must be same or else system will give an error

We can add materials as per requirement and once added click save

To see allocation consumption

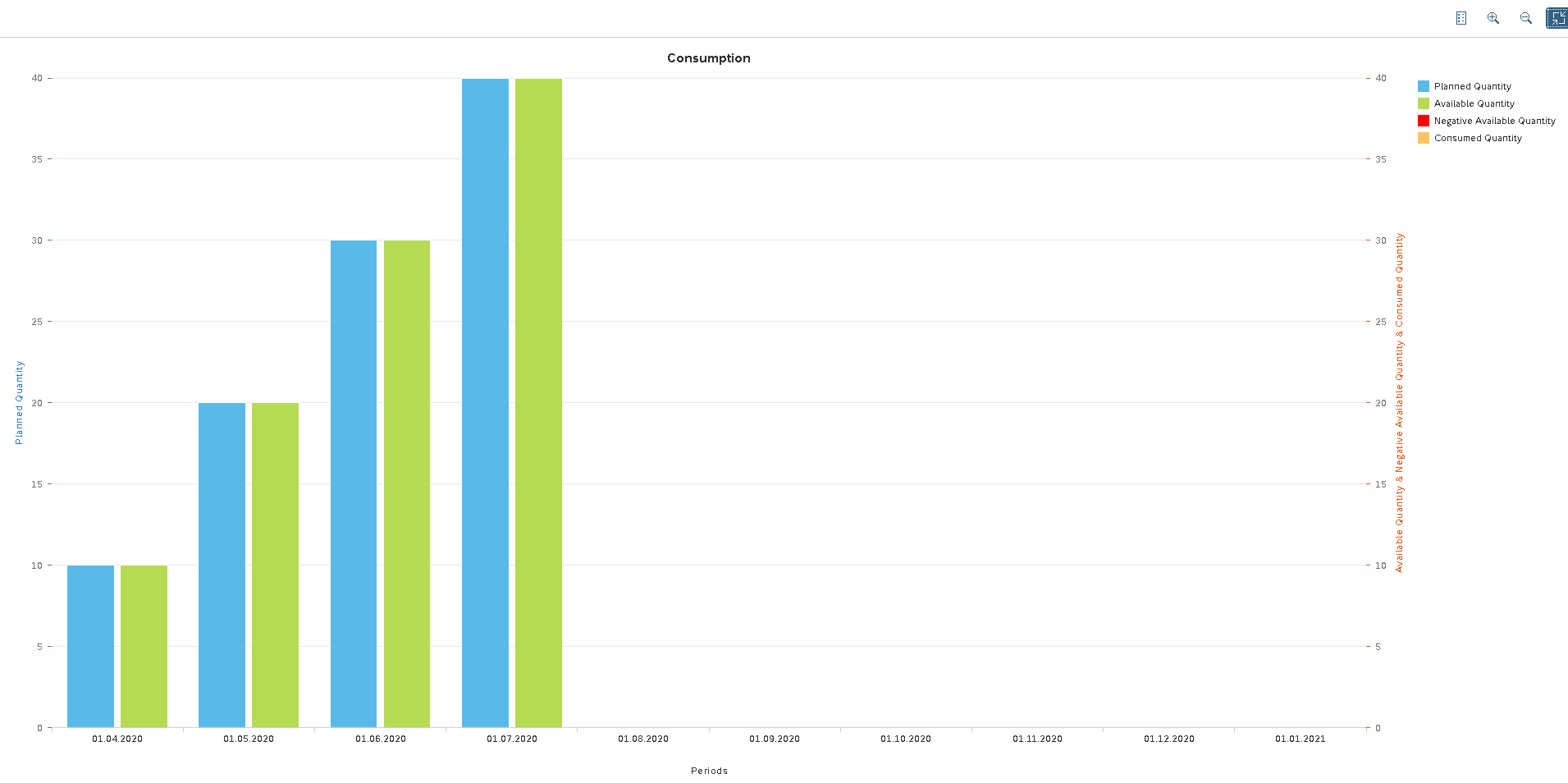

Allocation Object RUTHVIK PAL consumption is 0 now let us create a sales order and see

Created Sales order for FG126 with 20 Qty, but we have allocated only 10 in the month of April

From march to may it considered and allocated as per our allocation object

Now we can see Planned Qty Consumed Qty & available Qty

In this way, we can allocate product and delivery to customers without any delays

Please share, Like and Comment anything else you want to share or add points.

Thanks & Regards

Ruthvik Chowdary

SME – S/4HANA Logistics

SAP Ariba P2P

Welcome to another interesting topic, Product Allocation

In this blog, I would like to share process steps involved in Product Allocation

If you would like to know first what exactly product allocation is, Hear is a high-level overview

Competitive order processing that aims to deliver the required quantity to the customer at the requested time demands precise planning and control mechanisms. Unpredictable problems, such as breakdowns in production or increased demand, can lead to critical situations in order processing and must be brought under control before they arise.

Product allocations provide this sort of control and enable your company to avoid these critical situations in demand and procurement. Equal allocation of products in short supply must be possible, as must speedy reaction to bottlenecks and changing market situations.

Depending on the period, you can allocate products for specific customers or regions. Using product allocations in situations in which a product is in short supply, you can avoid allocating the entire available quantity to the first customer, which either delays the confirmation of subsequent sales orders or makes confirmation impossible.

Source SAP Library:- Product Allocation

Now let’s see how to activate Product Allocation

The system I used to execute PAL is S/4HANA 1909 FPS01

Once Activated PAL in SPRO rest everything needs to be done in Fiori there is no GUI transactions for PAL

Below are 5 Applications required to execute PAL

- Open Configure Product Allocation App

Click Create

Maintain Required Fields as per business requirement

Based on the requirement we can select both Sales orders and Stock Transfer Orders as well

Once General Information has maintained Click Characteristics and maintain

We can select characteristics based on the business requirement from the available list, if the available list is not compatible with the business we can add more characteristics via “Manage Characteristic Catalogs” app

Once maintained General Information & Characteristics save

- Open Manage Product Allocation Planning Data App

Click on Go to see previously created Allocation

Click on edit and then Add option to add characteristics which we have selected previously

In the Selection Range, we can select as per requirement

In allocation planning Data maintain Characteristic values and planning figures

The graph will be generated as per the values maintained in planning its Planned and available Quantity

Once all data maintained Save

- Now Open Manage Product Allocation Sequences App

Click on Create

In General, Information Tab maintain Required Fields

Backward consumption & Forward Consumption data need to be given

Its how many months system need to consider for allocating, System first goes backwards if no quantity available then system checks in forward

From 1909 onward Capacity Sequence groups have been introduced

Sales sequence groups are checked against product allocation before the product availability check. Capacity sequence groups are considered after the product availability check.

Open Sales sequence groups and from the drop-down select the Allocation Object which we created in 1st step

The time period can be given as per requirement

Once maintained all values click apply and save

- Open Assign Product to Product Allocation App

From Name itself, we can understand what needs to be done ?

From Name itself, we can understand what needs to be done ?We need to assign Material to Allocation Object

Note:- Unit of measure which we given initially while creation allocation object and materials which we add must be same or else system will give an error

We can add materials as per requirement and once added click save

- Open Product Allocation Overview App

To see allocation consumption

Allocation Object RUTHVIK PAL consumption is 0 now let us create a sales order and see

Created Sales order for FG126 with 20 Qty, but we have allocated only 10 in the month of April

From march to may it considered and allocated as per our allocation object

Now we can see Planned Qty Consumed Qty & available Qty

In this way, we can allocate product and delivery to customers without any delays

Please share, Like and Comment anything else you want to share or add points.

Thanks & Regards

Ruthvik Chowdary

SME – S/4HANA Logistics

SAP Ariba P2P

- SAP Managed Tags:

- SAP S/4HANA Cloud for Sales,

- SAP S/4HANA,

- SD (Sales and Distribution),

- SD Sales

40 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Advance Return Management complete configuration(SAP ARM) in Enterprise Resource Planning Blogs by Members

- SAP Fiori for SAP S/4HANA - Composite Roles in launchpad content and layout tools in Enterprise Resource Planning Blogs by SAP

- Integration of SAP Service and Asset Manager(SSAM) with SAP FSM to support S/4HANA Service Processes in Enterprise Resource Planning Blogs by SAP

- SAP Signavio Process Navigator turning 1-year old today! in Enterprise Resource Planning Blogs by SAP

- SAP Preferred Success: A Day in a Life in Product Change Management with Change Records in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |