- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- More Analytics Insights in SCM

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

iris_zimmermann

Active Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

01-30-2020

1:54 PM

Analytical insights into supply chain management topics are essential to identify and control deviations from targets as early as possible and take appropriate measures. Or you can use it to just follow the actual situation.

There are 3 new KPI's/reports available and 2 data source:

On Time in Full Delivered by Order Item: Report & KPI [OTIF Item]

The OTIF KPI's capture the delivery performance with respect to timeliness and completeness.

To complement the KPI 'On Time in Full Delivered by Sales Order' with an additional level, we provide a similar KPI that refers to the Sales Order Item level.

The KPI 'On Time in Full Delivered by Item' is rated o.k. if the single order item is rated as ‘on time’ and ‘complete’. So it provides a more detailed view.

Example: If a sales order has 3 items, and one is delayed, the KPI 'On Time in Full Delivered by Order Item' shows 67 % o.k. for the Sales Order. In contrast, the similar KPI on sales order level shows 0 %.

'Production Orders and Quantities': Report & KPI ‘Number of Production Orders’

The KPI 'Number of Production Orders' provides you with an overview of the number of production orders in the last 4 weeks. With drilling down, you can get insights of the planned, open and fulfilled quantities per finished product.

You can maintain the Target and Reference values reflecting your company's goals and needs in the KPI to make the absolute values comparable.The values are delivered empty because we cannot foresee the magnitude.

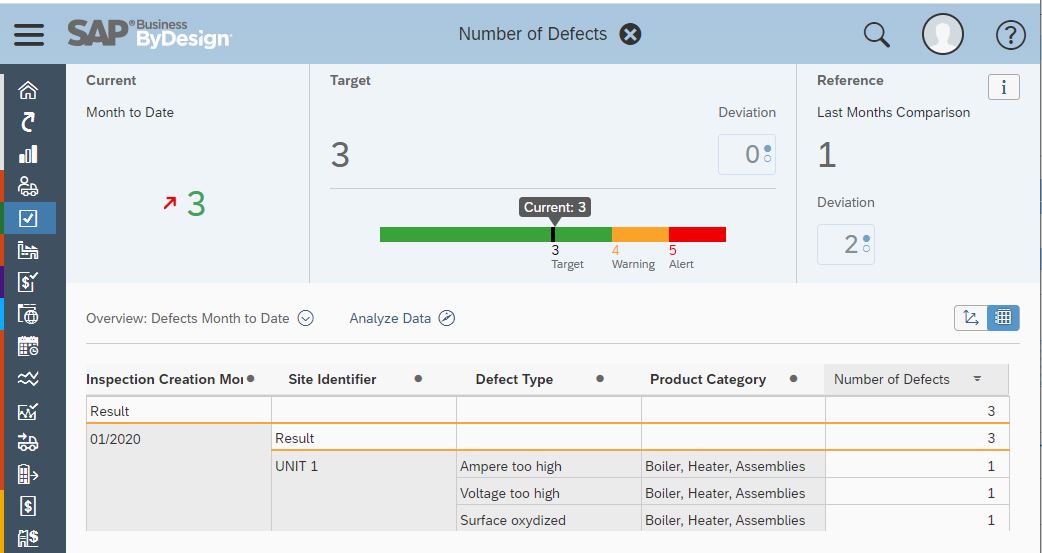

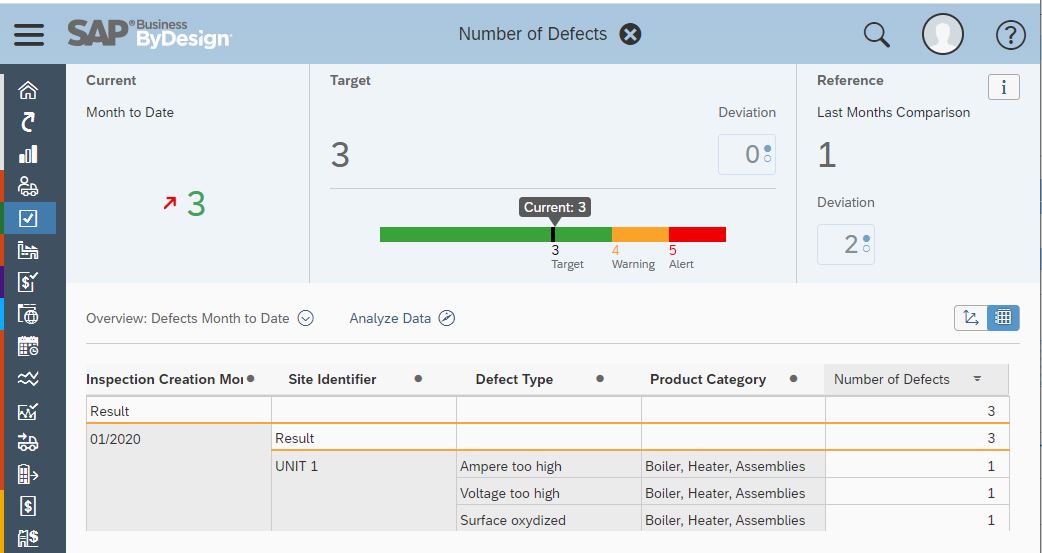

KPI 'Number of Defects'

In the area of quality inspections, you get with the 'Number of Defects' KPI an overview of the reported defects along with the defect types if you drill down more.

Be aware the target values are delivered empty because we cannot foresee the magnitude. In this screenshot it was maintained afterwards (small i Icon on the upper right corner).

Updated: Data Source Material Supply and Demand List Aggregated View

In supply planning, in the supply and demand list, a planner can see the supply in a detailed format, for example if for a planned receipt, the purchase order is created, acknowledged, or already advised or received inbound delivery notification. This is reflecting the reflecting also the reliability.

Now, we enhanced the aggregated data source ‘Material Supply and Demand List Aggregated View’ [SCMMSDVV01] to represent more in detail the incoming quantities in the same way as it is displayed in the supply and demand list.

You see a screenshot of a report build on this data source below:

The ‘former’ Key figure ‘Purchase Orders’ had aggregated all the 4-process status and is now renamed to ‘Purchase Orders Aggregated’. Purchase Orders without an acknowledgement or a subsequent Inbound Delivery Notification are now shown in the 'Purchase Orders' key figure.

New: Data Source Warehouse Request Items

Warehouse Requests are not always visible for customers using a lean process. Nevertheless, it more relevant for customers with extended process steps in warehousing or for internal logistics to initiate replenishment or removal or to trigger integration with a Third-Party-Logistics Provider (3PL).

Now, we provide you most of the data from the warehouse request item in one single data source [SCMWREXE_V1] including the main reference documents (such as sales order, purchase order and so on). With the help of the document type, you can identify the 3PL Requests.

You see a screenshot of a report build on this data source below:

There are 3 new KPI's/reports available and 2 data source:

- On Time in Full Delivered by Order Item: Report & KPI

- 'Production Orders and Quantities': Report & KPI ‘Number of Production Orders’:

- KPI 'Number of Defects'

- Updated: Data Source Material Supply and Demand List Aggregated View

- New: Data Source Warehouse Request Items

On Time in Full Delivered by Order Item: Report & KPI [OTIF Item]

The OTIF KPI's capture the delivery performance with respect to timeliness and completeness.

To complement the KPI 'On Time in Full Delivered by Sales Order' with an additional level, we provide a similar KPI that refers to the Sales Order Item level.

The KPI 'On Time in Full Delivered by Item' is rated o.k. if the single order item is rated as ‘on time’ and ‘complete’. So it provides a more detailed view.

Example: If a sales order has 3 items, and one is delayed, the KPI 'On Time in Full Delivered by Order Item' shows 67 % o.k. for the Sales Order. In contrast, the similar KPI on sales order level shows 0 %.

'Production Orders and Quantities': Report & KPI ‘Number of Production Orders’

The KPI 'Number of Production Orders' provides you with an overview of the number of production orders in the last 4 weeks. With drilling down, you can get insights of the planned, open and fulfilled quantities per finished product.

You can maintain the Target and Reference values reflecting your company's goals and needs in the KPI to make the absolute values comparable.The values are delivered empty because we cannot foresee the magnitude.

KPI 'Number of Defects'

In the area of quality inspections, you get with the 'Number of Defects' KPI an overview of the reported defects along with the defect types if you drill down more.

Be aware the target values are delivered empty because we cannot foresee the magnitude. In this screenshot it was maintained afterwards (small i Icon on the upper right corner).

Updated: Data Source Material Supply and Demand List Aggregated View

In supply planning, in the supply and demand list, a planner can see the supply in a detailed format, for example if for a planned receipt, the purchase order is created, acknowledged, or already advised or received inbound delivery notification. This is reflecting the reflecting also the reliability.

Now, we enhanced the aggregated data source ‘Material Supply and Demand List Aggregated View’ [SCMMSDVV01] to represent more in detail the incoming quantities in the same way as it is displayed in the supply and demand list.

You see a screenshot of a report build on this data source below:

The ‘former’ Key figure ‘Purchase Orders’ had aggregated all the 4-process status and is now renamed to ‘Purchase Orders Aggregated’. Purchase Orders without an acknowledgement or a subsequent Inbound Delivery Notification are now shown in the 'Purchase Orders' key figure.

New: Data Source Warehouse Request Items

Warehouse Requests are not always visible for customers using a lean process. Nevertheless, it more relevant for customers with extended process steps in warehousing or for internal logistics to initiate replenishment or removal or to trigger integration with a Third-Party-Logistics Provider (3PL).

Now, we provide you most of the data from the warehouse request item in one single data source [SCMWREXE_V1] including the main reference documents (such as sales order, purchase order and so on). With the help of the document type, you can identify the 3PL Requests.

You see a screenshot of a report build on this data source below:

- SAP Managed Tags:

- SAP Business ByDesign

Labels:

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

152 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

208 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

88

Related Content

- SAP Signavio Process Navigator turning 1-year old today! in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud Public Edition: Security Configuration APIs in Enterprise Resource Planning Blogs by SAP

- Building Low Code Extensions with Key User Extensibility in SAP S/4HANA and SAP Build in Enterprise Resource Planning Blogs by SAP

- fiscal year and standard year in the same model in SAP Analytics Cloud in Enterprise Resource Planning Q&A

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 8 | |

| 6 | |

| 5 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 |