- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- SAP EWM- Deconsolidation process

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member65

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

01-06-2020

10:34 AM

Purpose:

The purpose of this article to understand the deconsolidation process perform in EWM during Goods receipt, where we received the mixed materials HU from one supplier and before placing the material to final destination we first open the HU received from supplier take out the different material from it and packed the materials into Individual HU before final placement.

We can use deconsolidation for single material received from supplier or mixed material received in one pallet.

In this scenario, I have picked different material received from supplier in one Big pallet.

Deconsolidation

The deconsolidation settings are divided in five parts as below:

- Define work center

- Define deconsolidation Attribute

- Consolidation group mapping and Number Range mapping

- Process oriented storage control Mapping

- Master Data settings

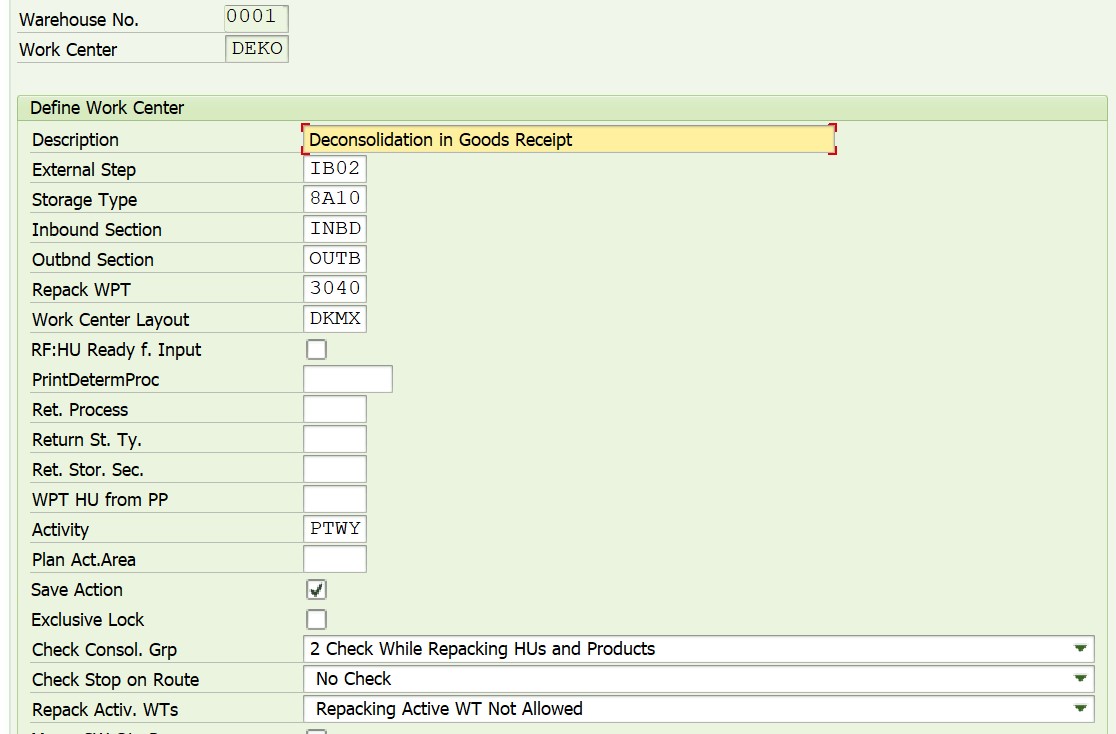

1) Define Work center for Deconsolidation (DEKO)

Deconsolidation work center is the place where all the incoming HU (mixed material HU or Single material HU or Large Material HU ( big in size) that need to be broken into small HU before final Put away.

SCM EWM →EWM→ Master Data → Work center→ Define work center

Define the work center (DEKO) : where the HU will be deconsolidated, define storage type, external step and Layout.

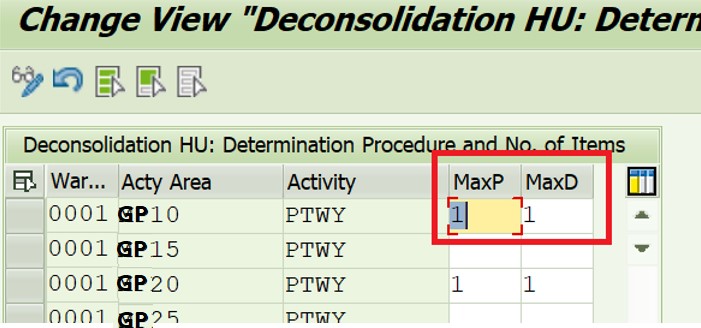

2. Deconsolidation Configuration (Attribute)

MaxD will help system to identify the number of warehouse task that Inbound HU can have beyond the number or exceeding the number the system will locate the HU to Deconsolidation Work center.

If the number of WT is lesser than the value defines in MaxD then system will not route the HU to Deconsolidation work center but directly put away the material based on put away strategy

MaxP the number of put way HU the system will create once the inbound HU is deconsolidated ( in Deconsolidate work center).

Path -> SPRO → EWM → Goods receipt process → Deconsolidation→ Define Attribute for Deconsolidation

SCM EWM → Goods receipt process → Deconsolidation→ Specify Deconsolidation Station

Maintain the warehouse, Source storage type and HU type group in combination of Work center. This combination is required so that system can identify where the HU needs to go after the inbound step is completed (if its meets above criterial MaxD, MaxP).

3. Consolidation Group Assignment

Assign consolidation group for Deconsolidation storage bin and final put away storage bin.

SCM EWM→ EWM → Master Data → Activity Area → Assign storage bin to activity area

Define Number range for Consolidation group

SCM EWM → Goods receipt process → Deconsolidation→ Assign Number Range interval to consolidate Group

Note:

- Do not forget to perform bin sorting (/n/SCWM/SBST) in case the setup for DECON (activity area, storage bin is new)

- Cross check the table if Consolidation group assignment is available in storage bin Table → /SCWM/LAGPS

4. Process Oriented Storage Control Mapping

SCM EWM → EWM → Cross process setting → Warehouse Task → Define process-oriented storage control

Go to process Oriented storage control tab and look for External step configuration settings related to DECON step IB02. Here activate the rule base config, were the system will search the storage bin based on the strategy and mapping done in Work center & under DECON attribute settings.

Assign Storage process INBG with warehouse process type and warehouse process type indicator and assign the Warehouse process type indicator in Product master.

Once system read the IB02 setting it will look for Work center where IB02 step settings are define and then based on the setting mention in the storage bin in combination of Storage type 8A10 and Inbound section - INBD, system will pick the storage bin -DECON.B

5. Master Data Setting :

Master data require for deconsolidation bin assignment with Work center→ /N/SCWM/TWORKST.

Process Flow:-

Step 1: create purchase order

Step 2: Create Inbound delivery: Perform packing during inbound delivery creation and delivery will be distributed to EWM.

Step 3: Access Inbound delivery in EWM and perform unloading. Tcode: /n/SCWM/IDN

Step 4: Perform UNLOADING using Unloading button

Step 5: System will create the Warehouse task to move the Stock/Hu from Doors to Goods receipt /Inbound (GR) area and another WT will be crate that will move the HU from GR Area to Deconsolidation Area -DEKO work center.

Go to Monitor using T-code : /n/SCWM/MON

Warehouse Order

Warehouse Task: The HU will be place in DECON.B bin after confirmation

Confirm the Warehouse task to move the material from Source BIN -123A to DECON.B bin. As of now the 2nd & 3rd line item of Warehouse task is set as ‘B’ → on hold, Once the DECON activity is done we can see the status changes from ‘B’ to ‘active’ for moving Decon HU to Final put away.

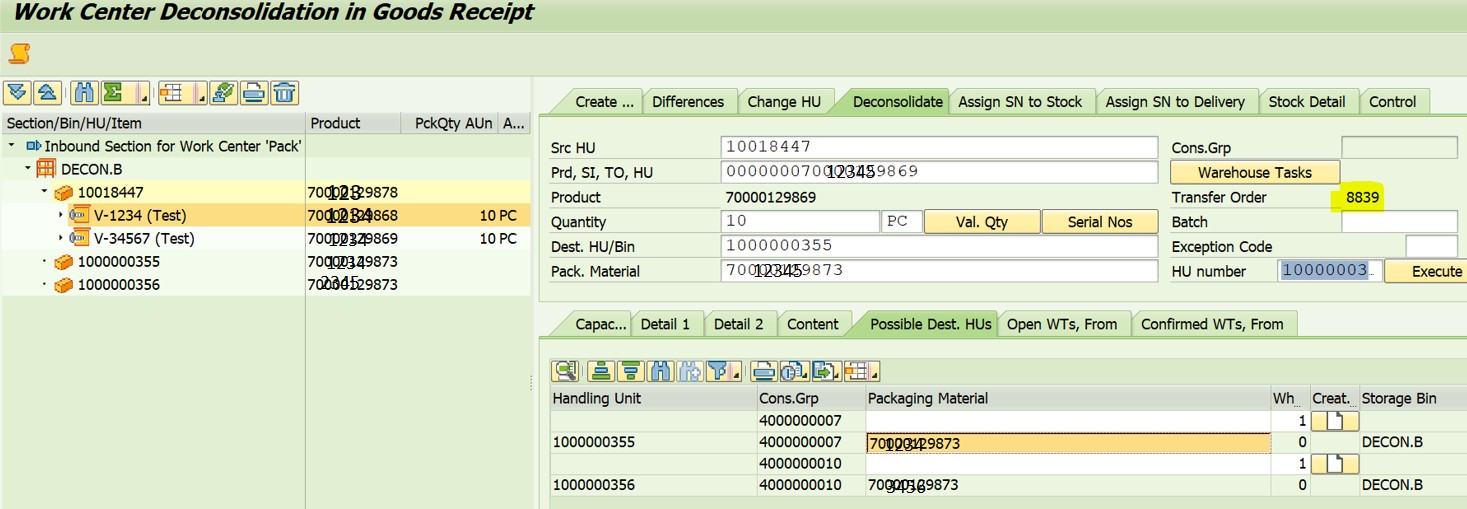

Step 6: Go to Deconsolidation Work center

Tcode /n/SCWM/DCONS

In selection screen enter the warehouse no and Work center ‘DEKO’ and execute or further filter it will possible options available on screen

In Decon Screen , select the possible destination HU tab , enter the packing material and enter the qty of HU that we want to be created to place/distribute the material and click on create button.

Generate the HU and place material from Big pallet to separate HU with required qty (for both material).

Step 7:Perform Complete HU process so that system will generate the Warehouse task to put away the HU’s to destination bin.

In Warehouse Monitor /n/SCWM/MON we can see that system has created the Warehouse task each for HU’s and the Status has been changed from ‘B-hold’ to Active.

Before HU step completion → The Warehouse task status

After HU step completion

Confirm the open warehouse task to move the material to final Destination bin.

Summary:

- The Deconsolidation process can be use in different putways process where one handling unit carrying mixed or single material can be break and packed into different handling unit depending upon warehouse HU settings and the packing specification maintained in system against the incoming material.

- The POSC will be used to perform different process step involved in Deconsolidation (like Unloading, Deconsolidation, Final put away).

- In EWM, deconsolidation should be triggered on following:

- If materials in HU belong to different activity area or different storage type and the final put away storage type are HU managed.

- Maximum number of warehouse task in the inbound HU is exceeded as define in system (Max D)

Regards

Nitin Solan

- SAP Managed Tags:

- SAP Extended Warehouse Management

14 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- SAP Business Network for Logistics 2404 Release – What’s New? in Supply Chain Management Blogs by SAP

- SAP Named a Leader in the 2024 Gartner Magic Quadrant for Transportation Management Systems in Supply Chain Management Blogs by SAP

- Advanced Shipping and Receiving Simplifying the Connectivity in Supply Chain Management Blogs by Members

- Control cycle for EWM IM managed slocs in Supply Chain Management Q&A

- Preferred Alternative UoM for Warehouse Operation in EWM in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 4 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |