- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- TM-EWM Integration with FO and TU in SAP S/4 Hana

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

petra_just

Active Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

01-01-2020

8:26 AM

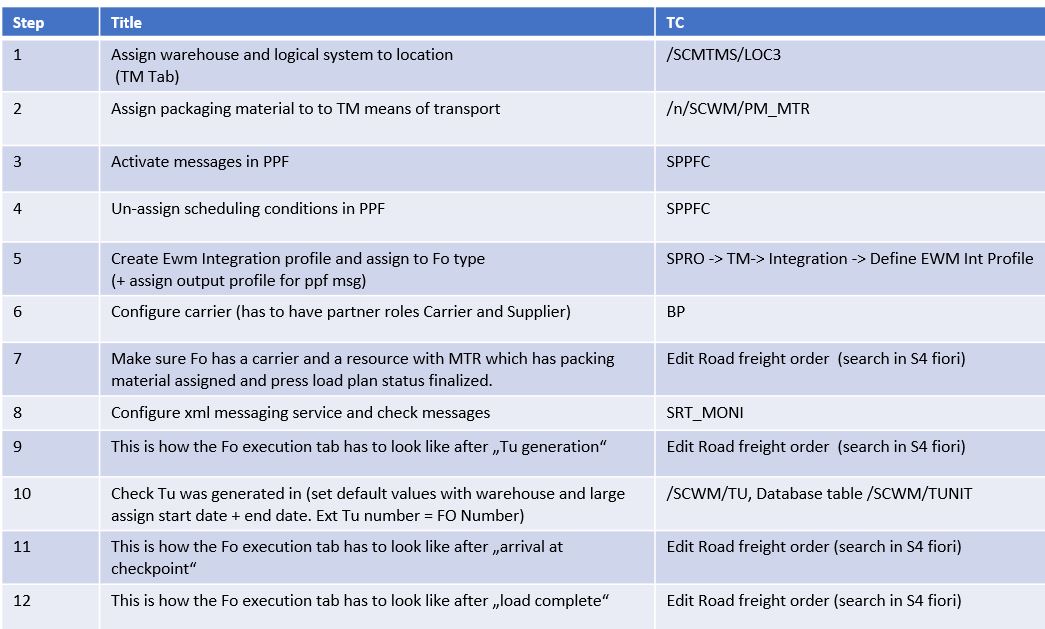

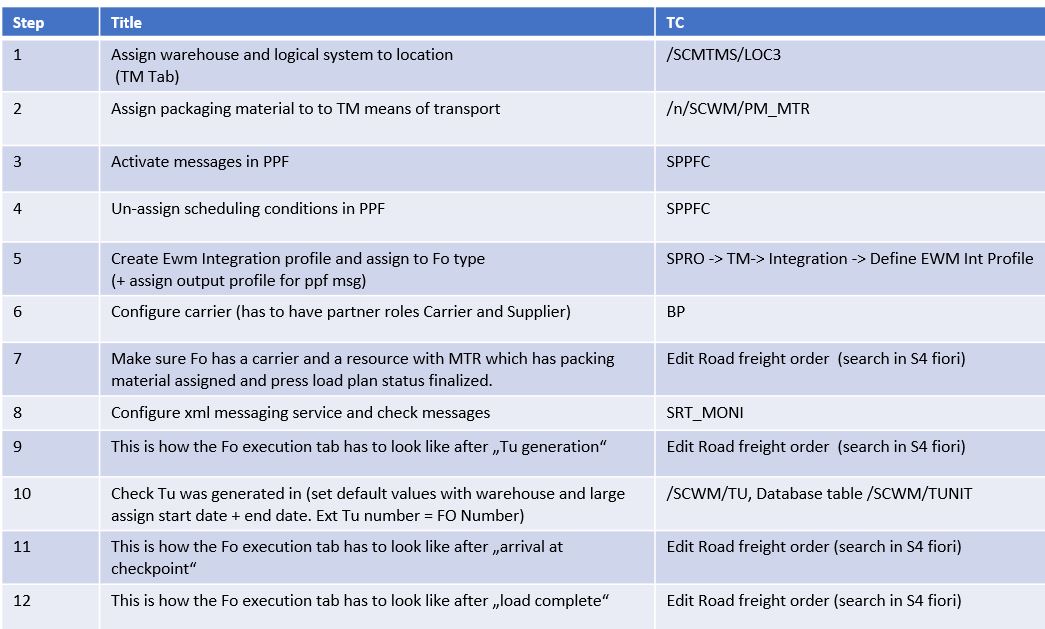

SAP S/4 Hana implementations that include EWM and TM need a certain set up to allow posting an end-to-end process with a sales order, delivery, freight unit, freight order, transportation unit, picking, packing and goods issue. The below step by step guide explains the most critical steps to allow freight order to transportation unit Integration. The below 12 steps summarize what needs to be done:

PICTURE 1 - STEP SUMMARY

PICTURE 2 - Location and packing material assignment

STEP 1 - Go to transaction /SCMTMS/LOC3

STEP 2 - Assign a warehouse and a Logical System to the related shipping point Location (TM tab)

STEP 3- Assign a packign material to the related means of Transport (same as the one in the resource used on the FO).

PICTURE 3 - Activate PPF messages

The TM to EWM Integration is done via an XML message (even in embedded TM and EWM). This means, the XML Framework needs to be set up and the following message type need activation.

STEP 1 - Go to SPPFC , choose /SCWM/SHP_REV and /SCMWM/TU

STEP 2 - activate the below marked messages

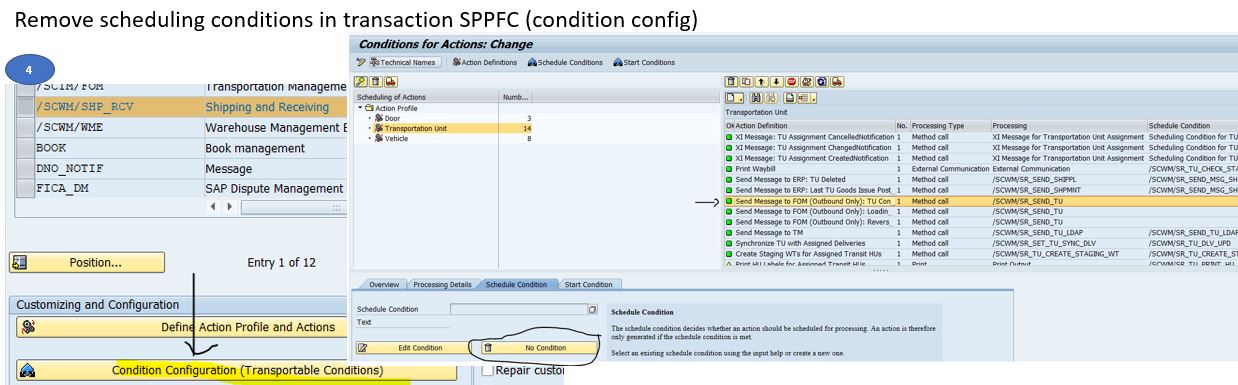

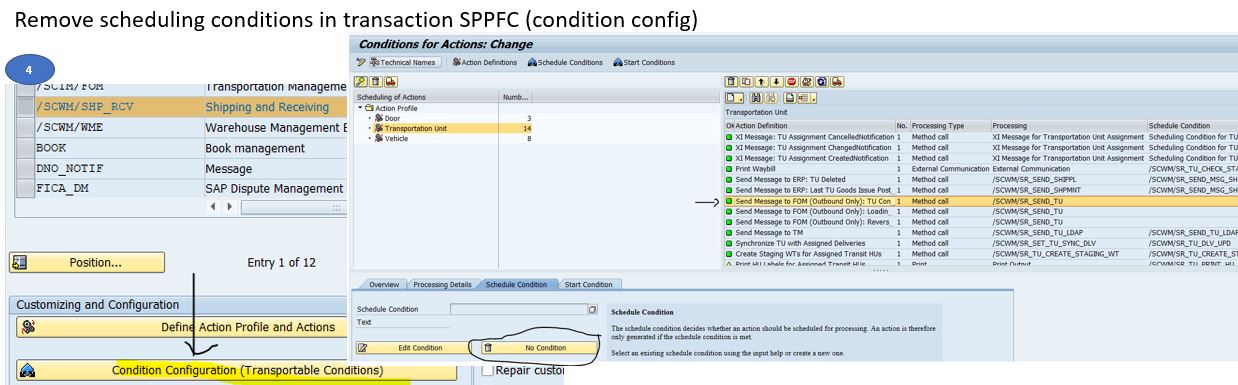

PICTURE 4 - Remove scheduling conditions

Scheduling condition check certain pre-requisites before they are executed. This will lead to non-generation of the Messages that you need if you do not remove them. double-click on the item on the Right side and click on "no condition" for each one of the messages.

PICTURE 5 - Configure ewm Integration profile and assign it to the FO type

SPRO -> TM-> Integration -> Define EWM Int Profile

SPRO -> TM – Freight order management – FO type

STEP 1 - Create Integration profile

Make sure to set multiple updates. This avoids that the Fo becoms uneditable after generating the TU.

STEP 2 - Assign Integration profile to the freight order type.

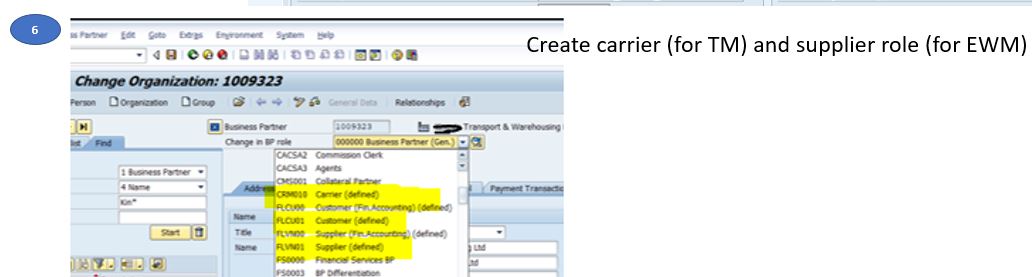

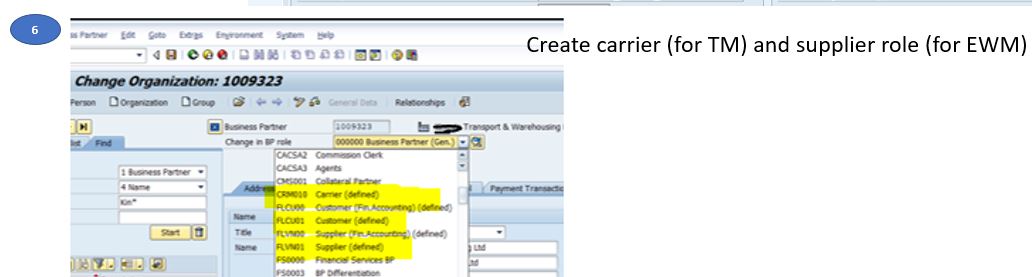

PICTURE 6 - Create carrier/supplier roles

STEP 1 - go to BP and Change to edit mode

STEP 2 - create carrier and supplier role

STEP 3 - this is required to add the carrier to the FO (TM) and receive it in ewm (supplier)

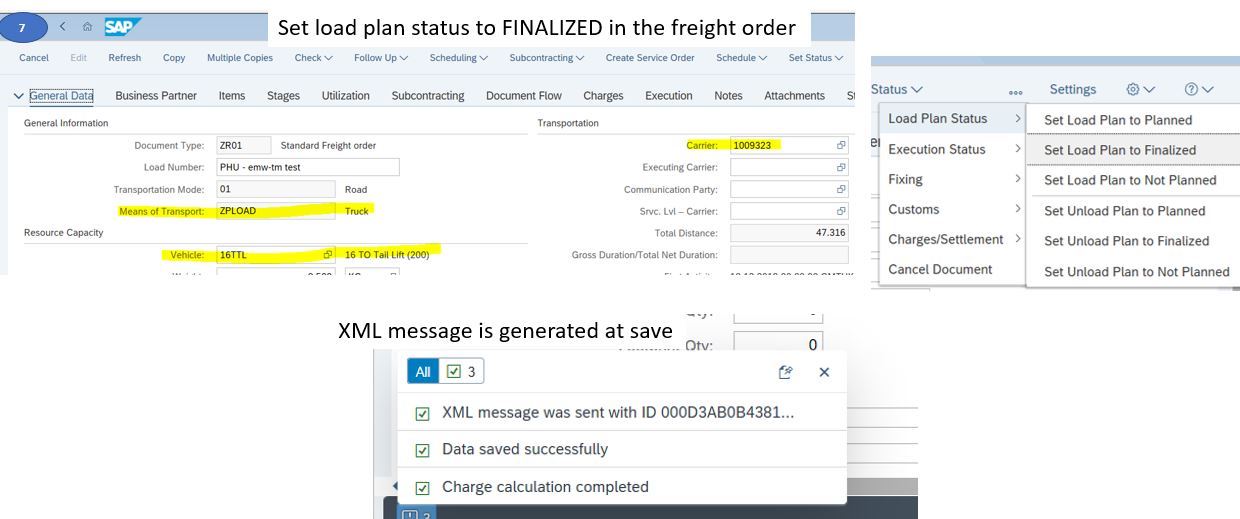

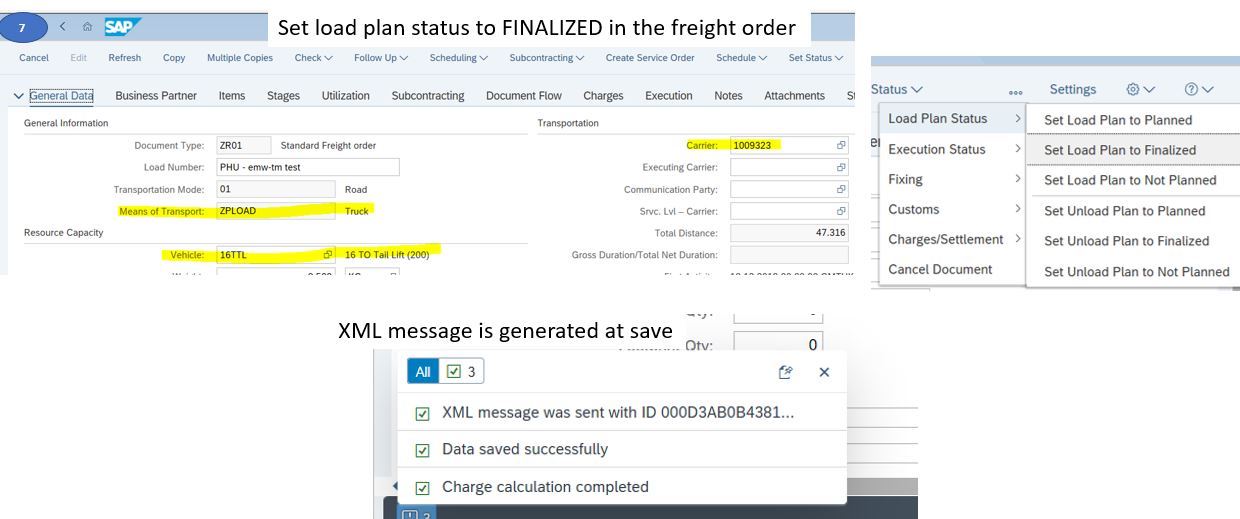

PICTURE 7 - Create Fo and set load plan Status to finalized

STEP 1 - Create the road freight order in TM

Type "edit road freight order" in sap business client or type/n/ui2/flp. Make sure, it has at least a carrier, a vehicle ressource and a freight unit assigned. The freight unit has to have a delivery generated that was distributed to EWM. Else the TU cannot be assigned to the delivery and will not be generated. The ressource have to have a Means of Transport with a package material assigned.

STEP 2 - Set load plan Status to finalized

If all goes well, a XML message is sent and you get the below message:

PICTURE 8 - Check Tu is created

STEP 1 - call transaction /SCWM/TU

Make sure the warehouse is correctly entered and the period for selection is long enough.

You can type the Fo number into TU external number. They are always the same and usually one to one. If you cannot find the TU, you can check in table /SCWM/TUNIT using TU_NUM_EXT. If it is not There. Check SRT_MONI.

PICTURE 9 - Check XML message

STEP 1 - call SRT_MONI

STEP 2 - Enter *LOAD* into interface Name.

PICTURE 10 - Post movements in EWM and Check Fo execution tab

STEP 1 - Tu Generation

Once the TU was generated successfully, the FO Shows Ready for loading on the execution tab.

STEP 2 - Arrival at Checkpoint

Once you have the TU in EWM, post "Arrival at checkpoint" to acknowledge truck arrival. The FO should show "arrival at Destination" on the execution tab.

STEP 3 - Load and Departure from checkpoint

Do picking, packing, load end and departure form checkpoint in ewm. The Fo execution tab should show the events LOAD_END and Departure with the same times as ewm.

These were the summarized steps to set up the TM-EWM integration.

regards

Petra Hunger

PICTURE 1 - STEP SUMMARY

PICTURE 2 - Location and packing material assignment

STEP 1 - Go to transaction /SCMTMS/LOC3

STEP 2 - Assign a warehouse and a Logical System to the related shipping point Location (TM tab)

STEP 3- Assign a packign material to the related means of Transport (same as the one in the resource used on the FO).

PICTURE 3 - Activate PPF messages

The TM to EWM Integration is done via an XML message (even in embedded TM and EWM). This means, the XML Framework needs to be set up and the following message type need activation.

STEP 1 - Go to SPPFC , choose /SCWM/SHP_REV and /SCMWM/TU

STEP 2 - activate the below marked messages

PICTURE 4 - Remove scheduling conditions

Scheduling condition check certain pre-requisites before they are executed. This will lead to non-generation of the Messages that you need if you do not remove them. double-click on the item on the Right side and click on "no condition" for each one of the messages.

PICTURE 5 - Configure ewm Integration profile and assign it to the FO type

SPRO -> TM-> Integration -> Define EWM Int Profile

SPRO -> TM – Freight order management – FO type

STEP 1 - Create Integration profile

Make sure to set multiple updates. This avoids that the Fo becoms uneditable after generating the TU.

STEP 2 - Assign Integration profile to the freight order type.

PICTURE 6 - Create carrier/supplier roles

STEP 1 - go to BP and Change to edit mode

STEP 2 - create carrier and supplier role

STEP 3 - this is required to add the carrier to the FO (TM) and receive it in ewm (supplier)

PICTURE 7 - Create Fo and set load plan Status to finalized

STEP 1 - Create the road freight order in TM

Type "edit road freight order" in sap business client or type/n/ui2/flp. Make sure, it has at least a carrier, a vehicle ressource and a freight unit assigned. The freight unit has to have a delivery generated that was distributed to EWM. Else the TU cannot be assigned to the delivery and will not be generated. The ressource have to have a Means of Transport with a package material assigned.

STEP 2 - Set load plan Status to finalized

If all goes well, a XML message is sent and you get the below message:

PICTURE 8 - Check Tu is created

STEP 1 - call transaction /SCWM/TU

Make sure the warehouse is correctly entered and the period for selection is long enough.

You can type the Fo number into TU external number. They are always the same and usually one to one. If you cannot find the TU, you can check in table /SCWM/TUNIT using TU_NUM_EXT. If it is not There. Check SRT_MONI.

PICTURE 9 - Check XML message

STEP 1 - call SRT_MONI

STEP 2 - Enter *LOAD* into interface Name.

PICTURE 10 - Post movements in EWM and Check Fo execution tab

STEP 1 - Tu Generation

Once the TU was generated successfully, the FO Shows Ready for loading on the execution tab.

STEP 2 - Arrival at Checkpoint

Once you have the TU in EWM, post "Arrival at checkpoint" to acknowledge truck arrival. The FO should show "arrival at Destination" on the execution tab.

STEP 3 - Load and Departure from checkpoint

Do picking, packing, load end and departure form checkpoint in ewm. The Fo execution tab should show the events LOAD_END and Departure with the same times as ewm.

These were the summarized steps to set up the TM-EWM integration.

regards

Petra Hunger

- SAP Managed Tags:

- SAP Extended Warehouse Management,

- SAP Transportation Management

52 Comments

- « Previous

-

- 1

- 2

- Next »

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

Digital Transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

ETA

1 -

EWM

5 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- RISE with SAP Advanced Logistics Package in Supply Chain Management Blogs by SAP

- SAP Field Logistics: Centralized Supplier Item Repository for an Optimized Rental Process in Supply Chain Management Blogs by SAP

- Drive productivity, safely and sustainably, with SAP manufacturing solutions in Supply Chain Management Blogs by SAP

- Transforming Your Supply Chain: Introducing RISE with SAP Advanced Logistics Package in Supply Chain Management Blogs by SAP

- Does SAP BN4L support Strategic Freight Procurement process ? in Supply Chain Management Q&A

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |