- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- EWM & QM integration in SAP S/4HANA 1909

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member27

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

12-12-2019

11:31 AM

For SAP S/4HANA 1909 system with embedded EWM, this blog lists provides an overview of configurations, key functionalities and limitations of EWM & QM integration

Following QM inspection types are supported with S/4HANA EWM

1701 EWM: Goods Receipt Insp. for Pur. Order

1704 EWM: Goods Receipt Insp. from production

1708 EWM: Stock transfer inspection

1709 EWM: Recurring inspection of batches

Now also standard inspection types are supported without inspection rule in SAP S/4HANA 1909 with embedded EWM

01 Goods receipt insp. for purchase order

04 Goods receipt inspection from production

08 Stock transfer inspection

09 Recurring inspection of batches

Basic Configuration & Master Data

In case of no inspection rule (EWM embedded in SAP S/4HANA 1909), inspection lot setup is set to no inspection rule.

Process oriented storage control step and quality stock status is set.

Code groups for usage decision needs to be updated for EWM usage decisions. Either new EWM codes are added to an existing code group or new code group is created with EWM codes.

Codes groups can be maintained per plant number, codes groups for plants managed by EWM and Non EWM can be differentiated using following configuration.

Please refer to OSS note 2787302 - EWM-QM integration without inspection rules when using embedded EWM

Inspection rules /scwm/qrsetup and inspection types 1701, 1704, 1708, 1709 are still available, please refer previous blog post for basic configuration steps.

https://blogs.sap.com/2019/05/23/ewm-qm-integration-in-sap-s4hana-1809/

Special Cases & Limitations

Inspection lots with “SKIP” status: When an inspection lot is created with “SKIP” status EWM would not update stock type but only delete inspection lot reference on stock. Therefore, if inbound delivery is created with quality stock type it would not be updated in EWM. In this case it would be better to allow EWM to decide final stock type based on inspection rule (/SCWM/QRSETUP).

Differentiating Purchaser Orders and Stock Transfer Orders for Inspection Lot Creation: Inspection lot setup can be differentiated for each inbound delivery type, in case delivery types cannot be for different inbound scenarios (like STO and PO case). Business partner field in inspection rule (SCWM/QRSETUP) can be used to differentiate different business cases (STO &PO) . For STO documents usually each sender plat/storage location would be defined as one business partner, a specific inspection rule can be set in (/SCWM/QRSETUP for partner that represent plant).

Moving Inspection stock from EWM managed storage location to IM-MM managed storage location: Inspection lot related stock in EWM warehouse cannot be transferred to IM-MM managed (non-EWM) managed storage locations in 1909 S/4HANA or previous releases.

Customer returns with quality inspection: Inspection of customer returns are only supported with Advance Return Management (ARM). When ARM is used with quality inspection document, QA32 EWM inspection or /SCWM/QINSP_S4 cannot be used for result entry. Partial inspection result entry based on handling unit is only possible with material inspection in warehouse tcode : MSR_INSPWH. Posting changes are replicated to EWM via delivery document. Please refer to OSS note 2806070 - SAP S/4HANA 1909: Release information and restrictions for EWM in SAP S/4HANA. Help Document : Integration with Warehouse Management

Partial result entry per HU: Quality inspection result entry from EWM is possible with quality inspection work center. Quality specific packaging work center in EWM can be used to repack handling units and enter partial inspection result for handling units: transection code /SCWM/QINSP_S4 - Quality Workload Overview. Partial decision functionality is available with S/4HANA 1709 SP01.

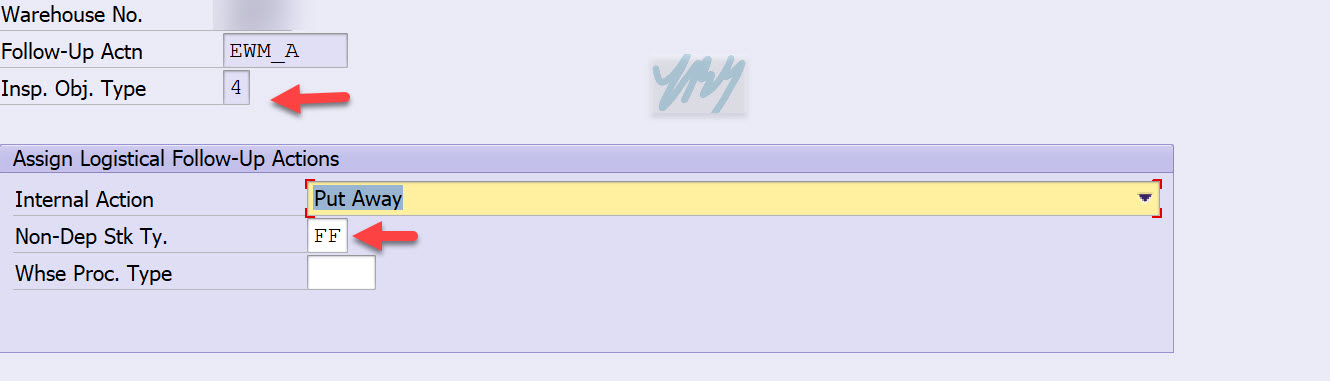

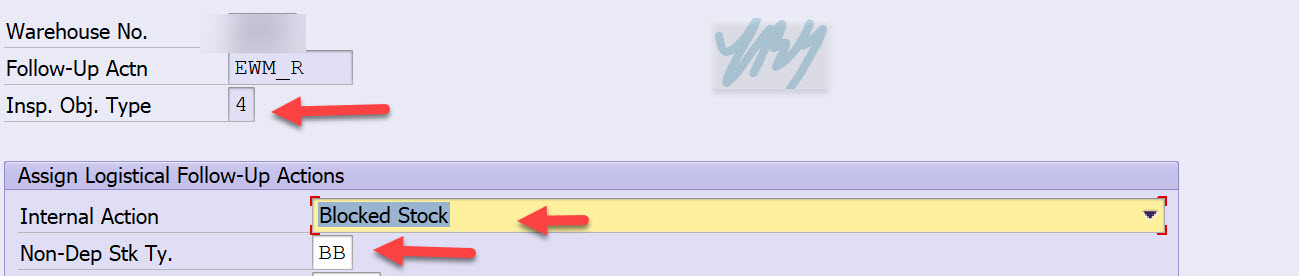

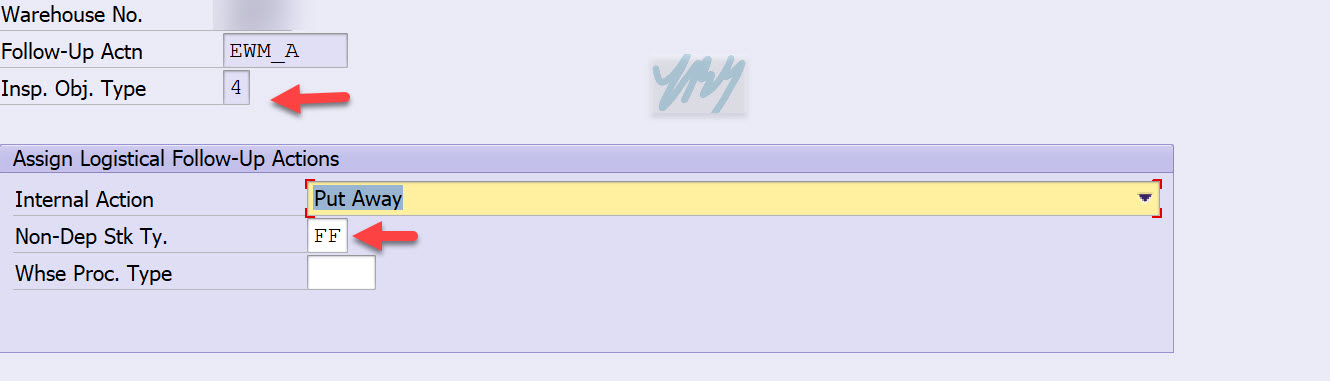

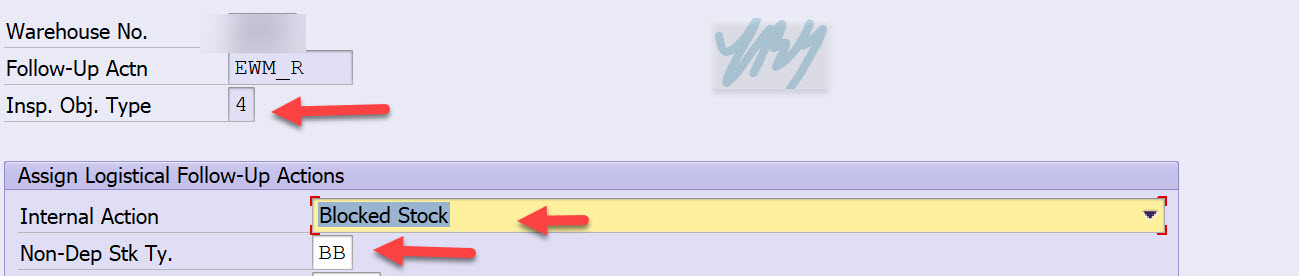

After QM inspection lot result entry follow-up actions can be triggered to create put away warehouse task.

Internal inspection lot creation from EWM: an inspection lot can be created for an available stock directly in EWM, for this purpose IOT5 should be activated and inspection type 1708 should be used. An inspection rule should be created in /scwm/qrsetup an generic inspection rule with owner can be used. Also, an exception code should be defined to record the requirement with following business contexts. Inspection lot creation using RF devices is also supported.

Creating internal inspection lot from EWM warehouse monitor

Acceptance Sampling with inspection rule: Inspection lot can be created before goods receipt posting with inbound delivery creation. Following configurations are required:

In case inspection rules are in use, then a specific inspection rule has to be maintained for acceptance sampling

In case inspection rules are not in use; a quality inspection info record is needed to trigger acceptance sampling. A new inspection type should be created with source inspection type 01 and maintained in quality inspection info record. Quality inspection material master data is required to be maintained accordingly.

Following follow up action can be configured:

Accept: Stock status would be updated to unrestricted, after goods receipt a second inspection lot is not created

Reject: Goods receipt is blocked.

Accept with reservations: Second inspection document is created after goods receipt.

With 1909 release, EWM QM integration simplified, bugs are fixed. Future improvements are expected in EWM &QM integration with new releases.

You’ve made it to the end, so feel free to comment ?

Following QM inspection types are supported with S/4HANA EWM

1701 EWM: Goods Receipt Insp. for Pur. Order

1704 EWM: Goods Receipt Insp. from production

1708 EWM: Stock transfer inspection

1709 EWM: Recurring inspection of batches

Now also standard inspection types are supported without inspection rule in SAP S/4HANA 1909 with embedded EWM

01 Goods receipt insp. for purchase order

04 Goods receipt inspection from production

08 Stock transfer inspection

09 Recurring inspection of batches

Basic Configuration & Master Data

In case of no inspection rule (EWM embedded in SAP S/4HANA 1909), inspection lot setup is set to no inspection rule.

Process oriented storage control step and quality stock status is set.

Code groups for usage decision needs to be updated for EWM usage decisions. Either new EWM codes are added to an existing code group or new code group is created with EWM codes.

Codes groups can be maintained per plant number, codes groups for plants managed by EWM and Non EWM can be differentiated using following configuration.

Please refer to OSS note 2787302 - EWM-QM integration without inspection rules when using embedded EWM

Inspection rules /scwm/qrsetup and inspection types 1701, 1704, 1708, 1709 are still available, please refer previous blog post for basic configuration steps.

https://blogs.sap.com/2019/05/23/ewm-qm-integration-in-sap-s4hana-1809/

Special Cases & Limitations

Inspection lots with “SKIP” status: When an inspection lot is created with “SKIP” status EWM would not update stock type but only delete inspection lot reference on stock. Therefore, if inbound delivery is created with quality stock type it would not be updated in EWM. In this case it would be better to allow EWM to decide final stock type based on inspection rule (/SCWM/QRSETUP).

Differentiating Purchaser Orders and Stock Transfer Orders for Inspection Lot Creation: Inspection lot setup can be differentiated for each inbound delivery type, in case delivery types cannot be for different inbound scenarios (like STO and PO case). Business partner field in inspection rule (SCWM/QRSETUP) can be used to differentiate different business cases (STO &PO) . For STO documents usually each sender plat/storage location would be defined as one business partner, a specific inspection rule can be set in (/SCWM/QRSETUP for partner that represent plant).

Moving Inspection stock from EWM managed storage location to IM-MM managed storage location: Inspection lot related stock in EWM warehouse cannot be transferred to IM-MM managed (non-EWM) managed storage locations in 1909 S/4HANA or previous releases.

Customer returns with quality inspection: Inspection of customer returns are only supported with Advance Return Management (ARM). When ARM is used with quality inspection document, QA32 EWM inspection or /SCWM/QINSP_S4 cannot be used for result entry. Partial inspection result entry based on handling unit is only possible with material inspection in warehouse tcode : MSR_INSPWH. Posting changes are replicated to EWM via delivery document. Please refer to OSS note 2806070 - SAP S/4HANA 1909: Release information and restrictions for EWM in SAP S/4HANA. Help Document : Integration with Warehouse Management

Partial result entry per HU: Quality inspection result entry from EWM is possible with quality inspection work center. Quality specific packaging work center in EWM can be used to repack handling units and enter partial inspection result for handling units: transection code /SCWM/QINSP_S4 - Quality Workload Overview. Partial decision functionality is available with S/4HANA 1709 SP01.

After QM inspection lot result entry follow-up actions can be triggered to create put away warehouse task.

Internal inspection lot creation from EWM: an inspection lot can be created for an available stock directly in EWM, for this purpose IOT5 should be activated and inspection type 1708 should be used. An inspection rule should be created in /scwm/qrsetup an generic inspection rule with owner can be used. Also, an exception code should be defined to record the requirement with following business contexts. Inspection lot creation using RF devices is also supported.

Creating internal inspection lot from EWM warehouse monitor

Acceptance Sampling with inspection rule: Inspection lot can be created before goods receipt posting with inbound delivery creation. Following configurations are required:

In case inspection rules are in use, then a specific inspection rule has to be maintained for acceptance sampling

In case inspection rules are not in use; a quality inspection info record is needed to trigger acceptance sampling. A new inspection type should be created with source inspection type 01 and maintained in quality inspection info record. Quality inspection material master data is required to be maintained accordingly.

Following follow up action can be configured:

Accept: Stock status would be updated to unrestricted, after goods receipt a second inspection lot is not created

Reject: Goods receipt is blocked.

Accept with reservations: Second inspection document is created after goods receipt.

With 1909 release, EWM QM integration simplified, bugs are fixed. Future improvements are expected in EWM &QM integration with new releases.

You’ve made it to the end, so feel free to comment ?

- SAP Managed Tags:

- SAP S/4HANA,

- EWM - Basis,

- EWM - Delivery Processing,

- EWM - Interfaces

Labels:

16 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

23 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

38 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

64 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- Early Stock Simulation for PMR documents Posting- Consumption & Consumption Reversal in Supply Chain Management Blogs by SAP

- SAP Intelligent Clinical Supply Management : Setup & Configuration in Supply Chain Management Blogs by Members

- Integration of SAP IBP with S4HANA and Ensuring Data Consistency with Machine Learning in Supply Chain Management Blogs by SAP

- Premium Hub CoE – DSC Knowledge Bits – “A simple setup guide to integrate SAP TM with Hana Spatial Service (HSS)” in Supply Chain Management Blogs by SAP

- Procuring Company Code in Transportation Management in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 9 | |

| 8 | |

| 6 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 |