- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- DHL's Smart Fulfillment Tasking System Nominated f...

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member63

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

11-22-2019

8:38 PM

Warehouse fulfillment is getting more complex with smaller orders and tighter cut off times. In this post, you will learn how we addressed this economically with the help of SAP WM.

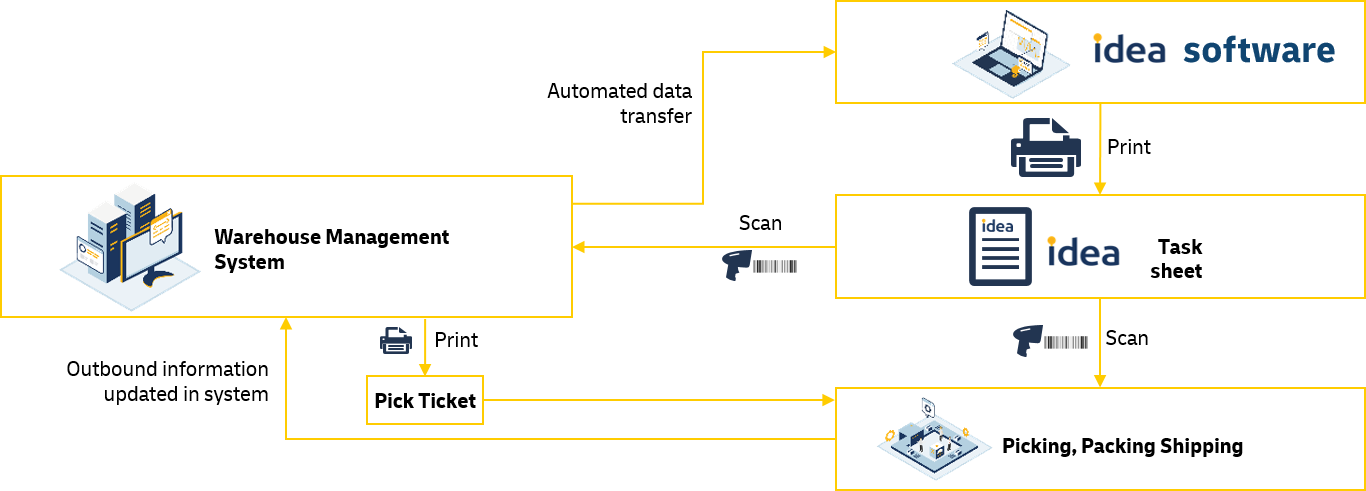

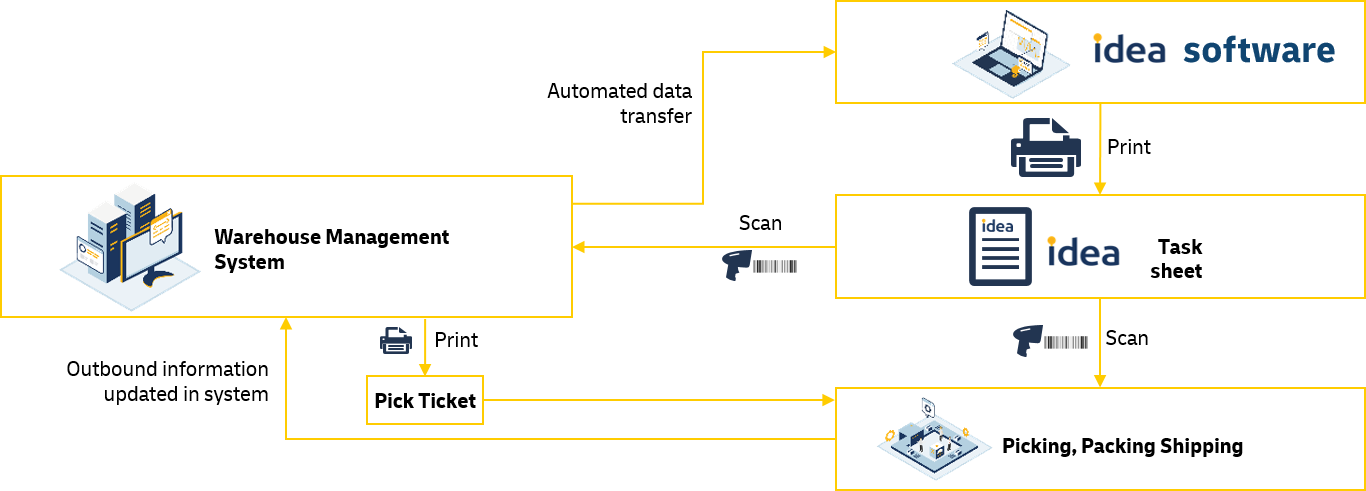

Per the diagram below, our solution imports open orders from SAP to our new tasking system called “Idea”.

From here, the warehouse planner would have visibility to orders by priority, type, transport mode and zone. The screen below shows open pick tasks by type and warehouse area. Allowing the warehouse wave planner to split out single vs multi-item orders (which can be picked differently) and create tasks that will have minimal travel distances.

Optimization is next, strategically clustering orders together onto pick carts to reduce travel distance. The diagram below shows, is a task sheet that includes 5 orders and 10 pick lines. Notice how all the picks are concentrated in just two aisles.

After, the generated tasks are sent back to SAP for execution as it remains the system of record.

In summary, this is a economical approach to add optimization logic into a warehouse operation with minimal integration and no additional hardware and automation. We do this by leveraging SAP's core WM module for communication, inventory management,

We are now honored to have our entry "IDEA: DHL’s Integrated Tasking System using Advanced Analytics to Optimize Fulfillment with SAP" accepted as a SAP 2020 Innovation Award nominee: https://www.sap.com/idea-place/sap-innovation-awards/submission-details-2020.html?idea_id=1030

Per the diagram below, our solution imports open orders from SAP to our new tasking system called “Idea”.

From here, the warehouse planner would have visibility to orders by priority, type, transport mode and zone. The screen below shows open pick tasks by type and warehouse area. Allowing the warehouse wave planner to split out single vs multi-item orders (which can be picked differently) and create tasks that will have minimal travel distances.

Optimization is next, strategically clustering orders together onto pick carts to reduce travel distance. The diagram below shows, is a task sheet that includes 5 orders and 10 pick lines. Notice how all the picks are concentrated in just two aisles.

After, the generated tasks are sent back to SAP for execution as it remains the system of record.

In summary, this is a economical approach to add optimization logic into a warehouse operation with minimal integration and no additional hardware and automation. We do this by leveraging SAP's core WM module for communication, inventory management,

We are now honored to have our entry "IDEA: DHL’s Integrated Tasking System using Advanced Analytics to Optimize Fulfillment with SAP" accepted as a SAP 2020 Innovation Award nominee: https://www.sap.com/idea-place/sap-innovation-awards/submission-details-2020.html?idea_id=1030

- SAP Managed Tags:

- SAP Extended Warehouse Management,

- SAP Supply Chain Management

2 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

ETA

1 -

EWM

5 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- Putzmeister Digitalized Global Field Service Management Processes to Increase Efficiency and Customer Satisfaction in Supply Chain Management Blogs by SAP

- Enhancing Customer Experience with Risk Resilient Supply Chain at BSH Home Appliances Group in Supply Chain Management Blogs by SAP

- Enhancing Customer Experience with Risk Resilient Supply Chain at BSH Home Appliances Group in Supply Chain Management Blogs by SAP

- Reply to Alex: need more work for the Milkman Post in Supply Chain Management Q&A

- SAP Integrated Business Planning for Supply Chain (SAP IBP) 2202 – Available Now! in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |