- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- MRP Live by S/4 HANA: Next Generation Planning Eng...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

ShekharDamale

Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

11-13-2019

6:04 PM

SAP S/4 HANA business suite is based on HANA in-memory platform. It brings several improvements over the conventional ECC business suite. SAP S/4 HANA is power packed with a new Fiori based user interface, updated data model, embedded analytics and capability of machine learning. SAP S/4 HANA brought a simplified approach to various business processes. The details of the simplifications are addressed in the Simplifications list. Simplification lists are release specific and published along with the release of S/4 HANA versions.

In this blog, we are going to see the advancement in SAP material requirement planning procedure. SAP S/4 HANA features the newly constructed MRP engine called MRP Live aka MD01n. MRP Live is optimized for SAP HANA database. This new MRP engine reads all the requirement elements (like Sales order, Production order, etc.), replenishment elements (like Purchase order, Stock transfer order etc.), calculates the shortages and creates the procurement proposals (planned orders and purchase requisitions) in single database procedure. This minimizes the data transfer from the database to the application server and back, which contributes to higher performance. MRP Live comes with additional features including the following:

Till date, MRP Live has some limitations as follows, (more details are in 1914010 - MD01N: Restrictions for Planning in MRP Live on HANA)

These limitations may or may not be addressed in future releases. The classic MRP programs are still part of the S/4 HANA release but not considered for future developments.

MRP Live Considerations

Before hitting to actual MRP Live screen, we will see the basic necessities to be mapped in the system.

Simplified Sourcing – Complexity in master data selection within the planning run is reduced in SAP S/4 HANA under the thought of simplified sourcing. The sourcing channels are described as below, (refer SAP Note 2268069 for details)

Planning file entry – Planning file entry structure has optimized in S/4 HANA to simplify the planning logic. The ECC planning file tables are replaced with single table PPH_DBVM. In migration activity, run report PPH_SETUP_MRPRECORDS is used to setup consistence planning file entries. Besides the setup report, the PPH_CONVERT_MRPRECORDS report will convert existing planning file entries to the PPH_DBVM table. (Refer SAP Note 2268088 for more details)

Planning Horizon – Planning horizon is the time axis restriction set in ECC customization. In ECC MRP transactions, the Planning key ‘NETPL’ is used to plan the material demands within the planning horizon. The material demands beyond the planning horizon are not counted in the planning run. This is to enhance processing and reduce the planning run time. SAP S/4 HANA MRP live plans all the materials irrespective of the planning horizon. The planning key ‘NETPL’ is no longer used. Regenerative planning is available for the first time MRP run.

MRP area planning The scope of existing MRP area functionality in ECC is broadened to accommodate the similar functionality of storage location planning. In ECC, storage location can be excluded from planning (in case of scrap or rejection location) or planned separately (in case of sub-contractor location). Now in SAP S/4 HANA, storage location level planning control is moved to the MRP area level. Storage location planning is not supported in S/4 HANA. MRP area creation is mandatory for storage locations which are managed separately in planning. Storage locations are assigned to the MRP area and further MRP area is planned as per the business requirement. User can set MRP type = ‘ND’ to exclude the material in planning for that particular MRP area. (Refer SAP Note 2268045 for further details)

For subcontracting planning, user need to create supplier specific MRP area and assign locations managed for the supplier. MRP parameters to be maintained in the MRP area view of the material master. (Refer SAP Note 2268044 for further details)

Evaluating the material master for MRP Live – SAP Note 1975704 provides the report PPH_CHECK_MRP_ON_HANA which displays the materials which cannot be planned by MRP live procedure along with the reason. The report also displays the number of materials that can be planned by MRP Live. The report has output options of Compact display and Detailed display.

Forcing material to plan in classic MRP – There can be few materials identified and required to be planned on classic MRP rather than MRP live procedure. Examples are, materials planned with reorder point (MRP Type = VB) with period or cost-based lot-sizing planning, forecast-based planning (MRP Type = VV) or materials with direct procurement. (Refer SAP Note 1914010 for further details). Such materials can be set to classical MRP procedure, by using transaction MD_MRP_FORCE_CLASSIC (Report -PPH_MRP_SET_PLAN_IN_ABAP) (Refer SAP Note 1914010 for further details). The materials which are not planned in MRP Live are transferred to classical MRP planning within MD01n run. No additional settings are required for this transfer.

MRP Live Screen

MRP Live screen is accessible with transaction MD01n or by report PPH_MRP_START in SE38. Background scheduling is possible with report PPH_MRP_START.

MRP Live selection screen is sub-divided into 3 sub-blocks. The detail parameters are as below:

MRP Planning

During the planning run, system determines the low-level codes as per the definition in the bill of material. After low-level code identification, the system starts planning with 0 level code. MRP Live will get first preference for material planning. If the system does not plan material with MRP live, then it gets planned in classic MRP procedure. Once both procedures are completed then the system moves to next low-level code.

MRP Results

MRP Live writes detail results regarding the planning run. The main screen depicts the Log Name, Time Stamp Details, User details, Number of Materials successfully planned, Number of materials failed in planning run, Number of materials planned with classic MRP program, Number of materials planned by MRP on HANA i.e. with HANA optimized MRP program and number of materials planned with default product heuristic maintained in material master. The log can be accessed at any time after planning run with transaction MD_MRP_PERFLOG.

The MRP Level view shows the code level and time details required for processing.

Stock requirement display is same as transaction MD06 – Collective Stock Requirement List.

“Materials with message” tab shows the messages raised by material within the planning run. This is analogous functionality to exception messages in MD04. User can click ‘Solve Issue’ to address the problem raised in the planning run.

The advanced planning log (Shift +F2) describes the log raised within the product heuristic run.

Hope you all find this blog useful & informative. SAP keeps on upgrading the MRP Live functionality with every new release. Stay tuned for more SAP updates.

Regards,

Chandrashekhar

References

In this blog, we are going to see the advancement in SAP material requirement planning procedure. SAP S/4 HANA features the newly constructed MRP engine called MRP Live aka MD01n. MRP Live is optimized for SAP HANA database. This new MRP engine reads all the requirement elements (like Sales order, Production order, etc.), replenishment elements (like Purchase order, Stock transfer order etc.), calculates the shortages and creates the procurement proposals (planned orders and purchase requisitions) in single database procedure. This minimizes the data transfer from the database to the application server and back, which contributes to higher performance. MRP Live comes with additional features including the following:

- The planning scope is more flexible than classical MRP (ABAP based MRP). Single transaction MD01n covers the functionalities of MD01/MD02/MD03 transactions.

- Cross plant planning is possible in single MRP Run. The planner can plan a set of materials across plants to the component level. The low-level code calculation decides the planning hierarchy of materials.

- The material planning part of Embedded PP/DS (e-PPDS) is considered in MD01n development.

Till date, MRP Live has some limitations as follows, (more details are in 1914010 - MD01N: Restrictions for Planning in MRP Live on HANA)

- MD01n does not write MRP List. SAP suggests using MD04 which shows a more live situation.

- Make-To-Order, Multilevel sale order specific planning (MD50) is not optimized for S/4 HANA.

- Project based planning (MD51) is not optimized for S/4 HANA.

- The creation Indicator for purchase requisition is not supported in MD01n. MRP live doesn’t consider opening period. The system creates the purchase requisition if the procurement type is ‘F’. This will reduce the planned order to purchase requisition conversion step.

- The creation indicator for schedule lines is not supported in Md01n. The system will create a schedule line if a valid agreement exists.

These limitations may or may not be addressed in future releases. The classic MRP programs are still part of the S/4 HANA release but not considered for future developments.

MRP Live Considerations

Before hitting to actual MRP Live screen, we will see the basic necessities to be mapped in the system.

Simplified Sourcing – Complexity in master data selection within the planning run is reduced in SAP S/4 HANA under the thought of simplified sourcing. The sourcing channels are described as below, (refer SAP Note 2268069 for details)

- Production version (In-house Procurement) - Production version is mandatory if the procurement type is ‘E’ or ‘X’. The production version should be not locked but should be active for automatic sourcing to read in MRP Live. This simplification has discontinued the ‘selection Method’ (MARC-ALTSL) field in MRP4 View. The system picks the first valid production version. For those who are migrating from ECC to S/4 HANA refer SAP Note 2655077 for automatic creation of production version.

- Purchasing Info Record (External Procurement) – System will consider the valid purchasing info record which has procurement type ‘F’ and ticked for ‘Relevant for automatic sourcing’ in MRP live.

- Purchasing contracts and delivery schedules are selected in MRP live if maintained as procurement type ‘F’.

- For material with multiple procurement sources, the system will refer to the quota arrangement maintained in transaction MEQ1. Quota arrangement is an integral part of the MRP live. Field quota arrangement usage (MARC- USEQU) in MRP 2 view is discontinued in SAP S/4 HANA. The rest of the master data definitions and structures are intact and referred in MRP live run.

Planning file entry – Planning file entry structure has optimized in S/4 HANA to simplify the planning logic. The ECC planning file tables are replaced with single table PPH_DBVM. In migration activity, run report PPH_SETUP_MRPRECORDS is used to setup consistence planning file entries. Besides the setup report, the PPH_CONVERT_MRPRECORDS report will convert existing planning file entries to the PPH_DBVM table. (Refer SAP Note 2268088 for more details)

Planning Horizon – Planning horizon is the time axis restriction set in ECC customization. In ECC MRP transactions, the Planning key ‘NETPL’ is used to plan the material demands within the planning horizon. The material demands beyond the planning horizon are not counted in the planning run. This is to enhance processing and reduce the planning run time. SAP S/4 HANA MRP live plans all the materials irrespective of the planning horizon. The planning key ‘NETPL’ is no longer used. Regenerative planning is available for the first time MRP run.

MRP area planning The scope of existing MRP area functionality in ECC is broadened to accommodate the similar functionality of storage location planning. In ECC, storage location can be excluded from planning (in case of scrap or rejection location) or planned separately (in case of sub-contractor location). Now in SAP S/4 HANA, storage location level planning control is moved to the MRP area level. Storage location planning is not supported in S/4 HANA. MRP area creation is mandatory for storage locations which are managed separately in planning. Storage locations are assigned to the MRP area and further MRP area is planned as per the business requirement. User can set MRP type = ‘ND’ to exclude the material in planning for that particular MRP area. (Refer SAP Note 2268045 for further details)

For subcontracting planning, user need to create supplier specific MRP area and assign locations managed for the supplier. MRP parameters to be maintained in the MRP area view of the material master. (Refer SAP Note 2268044 for further details)

Evaluating the material master for MRP Live – SAP Note 1975704 provides the report PPH_CHECK_MRP_ON_HANA which displays the materials which cannot be planned by MRP live procedure along with the reason. The report also displays the number of materials that can be planned by MRP Live. The report has output options of Compact display and Detailed display.

Forcing material to plan in classic MRP – There can be few materials identified and required to be planned on classic MRP rather than MRP live procedure. Examples are, materials planned with reorder point (MRP Type = VB) with period or cost-based lot-sizing planning, forecast-based planning (MRP Type = VV) or materials with direct procurement. (Refer SAP Note 1914010 for further details). Such materials can be set to classical MRP procedure, by using transaction MD_MRP_FORCE_CLASSIC (Report -PPH_MRP_SET_PLAN_IN_ABAP) (Refer SAP Note 1914010 for further details). The materials which are not planned in MRP Live are transferred to classical MRP planning within MD01n run. No additional settings are required for this transfer.

MRP Live Screen

MRP Live screen is accessible with transaction MD01n or by report PPH_MRP_START in SE38. Background scheduling is possible with report PPH_MRP_START.

MRP Live selection screen is sub-divided into 3 sub-blocks. The detail parameters are as below:

- Planning Scope

- Multiple plants input is possible in MD01n as compared to single input in MD01 / MD02 / MD03. Multi Plants or Cross Plant planning is possible in single execution.

- Multiple materials input is possible in MD01n as compared to MD01 / MD02 / MD03. Multi material planning is possible in single execution.

- Multiple Product groups are planned in single execution.

- User can restrict the material planning at selected MRP controllers.

- Material Scope denotes the materials to be included in planning. In that,

- A – All materials are planned in the run

- M - Only materials with MRP as planning procedure are planned

- S - Only materials with MPS as planning procedure are planned

- Also to be Included in Planning

- Changed BOM Components - System will include the components which are changed during this planning run.

- All Order BOM Components - System will include all the order BOM components in the planning run.

- Stock transfer materials – This selection will plan the materials in supplying plants provided required authorizations are available.

- Control Parameters

- Regenerative Planning – The system will consider all materials in planning. This is for the initial run after planning the file entry setup.

- Scheduling – Selection mode for basic date scheduling or detailed scheduling.

- Planning Mode – Mode to select procurement proposal generation

- Adapt Planning Data – System will find the unfirmed procurement proposals and use them in planning for receipt calculation

- Delete and recreate planning – System deletes all unfirmed proposals and creates fresh ones.

- Name for Performance log - User can give a suitable name to capture planning log details.

MRP Planning

During the planning run, system determines the low-level codes as per the definition in the bill of material. After low-level code identification, the system starts planning with 0 level code. MRP Live will get first preference for material planning. If the system does not plan material with MRP live, then it gets planned in classic MRP procedure. Once both procedures are completed then the system moves to next low-level code.

MRP Results

MRP Live writes detail results regarding the planning run. The main screen depicts the Log Name, Time Stamp Details, User details, Number of Materials successfully planned, Number of materials failed in planning run, Number of materials planned with classic MRP program, Number of materials planned by MRP on HANA i.e. with HANA optimized MRP program and number of materials planned with default product heuristic maintained in material master. The log can be accessed at any time after planning run with transaction MD_MRP_PERFLOG.

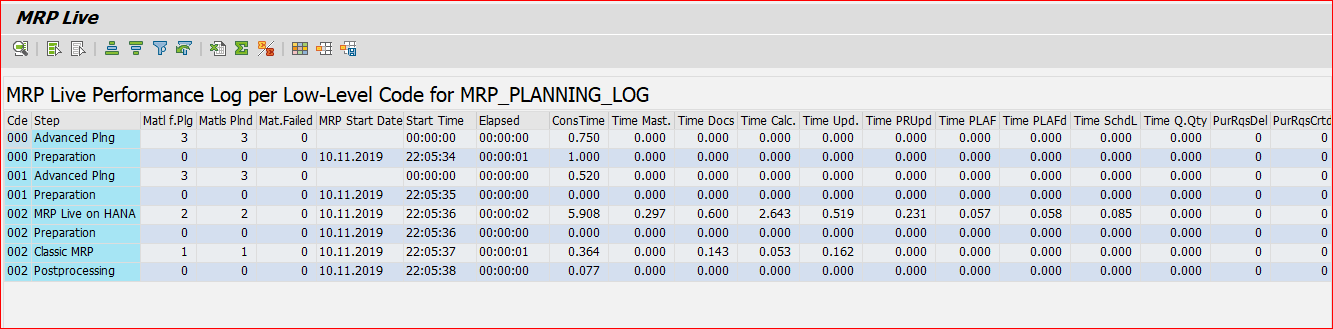

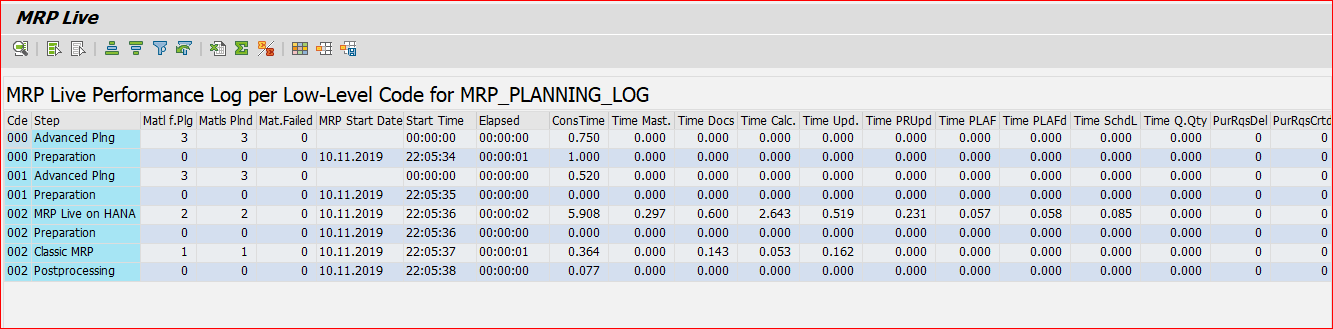

The MRP Level view shows the code level and time details required for processing.

Stock requirement display is same as transaction MD06 – Collective Stock Requirement List.

“Materials with message” tab shows the messages raised by material within the planning run. This is analogous functionality to exception messages in MD04. User can click ‘Solve Issue’ to address the problem raised in the planning run.

The advanced planning log (Shift +F2) describes the log raised within the product heuristic run.

Hope you all find this blog useful & informative. SAP keeps on upgrading the MRP Live functionality with every new release. Stay tuned for more SAP updates.

Regards,

Chandrashekhar

References

| SAP Note 2567573 | Storage location excluded from MRP on S_4 HANA |

| SAP Note 2268045 | Storage Location MRP |

| SAP Note 1975704 | Evaluating the material masters for MRP live |

| SAP Note 2268069 | Simplified Sourcing |

| SAP Note 2655077 | Migration Report CS_BOM_PRODVER_MIGRATION02_ Automatic Creation of Production Versions from valid BOMs and Routings |

| SAP Note 1914010 | MD01N Restrictions for Planning in MRP Live on HANA |

| SAP Note 2640393 | Differences between t-code MD01N and classic MRP t-codes MD01 / MD02 / MD03 |

| SAP Note 2268085 | MRP live on SAP HANA - MD01N |

| SAP Note 2268088 | Planning File |

| SAP 1809 FPS02 | Simplification List 1809 FPS02 |

- SAP Managed Tags:

- SAP S/4HANA,

- MAN Production Planning (PP)

7 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- How to Create Outbound Delivery With order reference in SAP VL01N in Enterprise Resource Planning Blogs by Members

- Creation of Outbound Delivery using VL01N in SAP in Enterprise Resource Planning Q&A

- Purchase Order Accrual in S/4HANA - Part 2 in Enterprise Resource Planning Blogs by Members

- Demystifying Transformers and Embeddings: Some GenAI Concepts in Enterprise Resource Planning Blogs by SAP

- Deep Dive into SAP Build Process Automation with SAP S/4HANA Cloud Public Edition - Retail in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |