- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Sales Process Integration with E-Commerce Sites / ...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Abinathsiva

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-09-2019

6:19 PM

Introduction

In this blog would like to share the process of E-commerce sales integration with SAP. E-comm site like Amazon / Flipkart / Paytm etc., will provide the data through API or flat file output in Excel / CSV format.

Exact Industry Requirement:

Most of the orders in Third party site will be having a combo product (combo product), if combo product is in order, we have two options

The industry opts for option 2. In this sales order requirement should flow through production order process.

Steps involved for this Automation:

Brief process flow as intro

Prerequisites to follow below mentioned steps:

Create a customer as onetime customer since industrial requirement does not have multiple customers for online sales (i.e., web/ e-comm sales). And check box of complete delivery should be enabled.

In order to have a control on Inventory activities, suggested to go ahead with single production order for a period (i.e., one Production Order for month) based on this all required output material will be created as co-product and output will be picked through 101 movement type.

Note: Though creation of production order also can be automated recommended creating production order manually since it’s a onetime activity.

Since every Third-party site has unique format of output file upload, individual radio buttons been provided of user to select and upload the required Orders.

Validations are in place with Purchase order reference and Purchase order date reference to avoid duplicate Sales order upload.

Verified Sales orders will be given as input to another program as follows for ease of approach program written with different performs based on activities.

And the selection screen for end user shown as follows :

here alternate plant is finding inventory available in alternate plant and proceed with Transfer posting for performing Production/pgi process for the execution plant.

All sales order document flow will be verified and validated before proceeding with OBD and Invoice.

Wherever inventory check is required in this whole process call standard MB52 through submit and get the result and write required validations.

a) For regular product system will suggest for Transfer posting from existing Plant to required plant

b) For combi product – BOM will be explored and inventory will be verified if available push to next step, not available step 5) 1. will be triggered for the existing BOM components required quantity.

followed by this IT_MAST will have complete component list and required quantity for a sales order, before proceeding to production order Inventory check initiated and availability check executed.

Through BAPI BAPI_PRODORD_GET_DETAIL production order will be read, and Finished goods will be added to prod. ord. as a co-product.

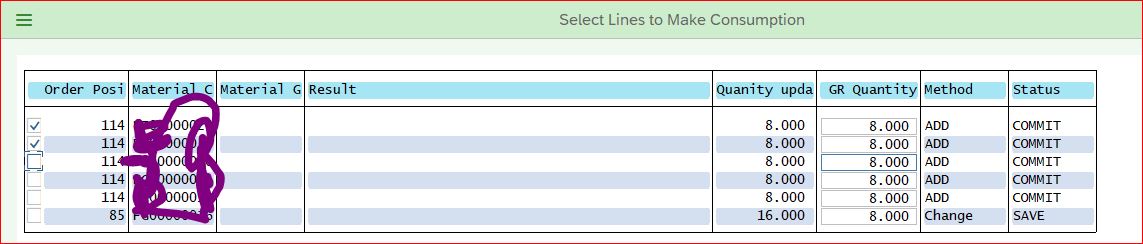

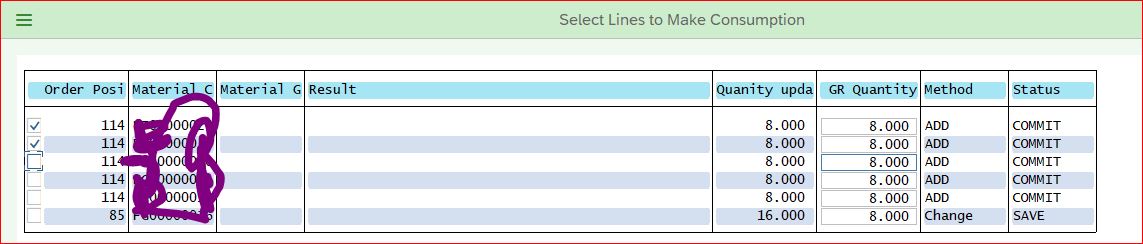

Component for the above mentioned Finished Good added into the same prd.ord. followed by GRN consumption entry posted based on selection.

8. Repetition of step 4 for inventory check and proceed as mentioned.

based on availability flag end user can select the Sales order to proceed for OBD.

List of all BAPI's and FM used to achieve above process :

Though most of the FM and BAPI's are known to most of the SAP consultants like to list for ease of understanding.

ALSM_EXCEL_TO_INTERNAL_TABLE - loading data from excel to internal table.

CS_BOM_EXPL_MAT_V2 - for BOM exploration.

BAPI_SALESORDER_CREATEFROMDAT2 - for Sales order creation with all condition types.

REUSE_ALV_POPUP_TO_SELECT - for all line selection option provided to users

BAPI_PRODORD_GET_DETAIL - for reading the production order data.

HR_JP_MONTH_BEGIN_END_DATE - to validate the production order in posting date's period.

CO_XT_COMPONENT_ADD - to add components to existing production order if the Finished goods are new to the production in the month. For both co-product or consumption product.

CO_XT_COMPONENT_CHANGE - this is to change the component which already present in the production order. For both co-product or consumption product.

BAPI_DELIVERYPROCESSING_EXEC & WS_DELIVERY_UPDATE - OBD/PGI positing after inventory check.

BAPI_BILLINGDOC_CREATEMULTIPLE - for the creating Invoice based on OBD/PGI

GUI_DOWNLOAD - Output / error file download to specified location for end user verification.

above listed BAPI's / FM is for present Industrial requirement, If industrial requirement is to create individual production for all Combo product or for any fresh regular finished goods through production order, which also can be addressed through production order creation BAPI, and Production order Post BAPI.

Conclusion:

Would like to conclude the above steps and functionality to achieve integration with real time challenges in this process automation are listed with the validation and implemented by futuristic thought of all statutory condition, inventory process, accounting entry, etc., further based on UAT and process flaws more number of validation may require to bring into the process as of now which ever considered as a requirements has been addressed and moved to production environment and given to users.

In this blog would like to share the process of E-commerce sales integration with SAP. E-comm site like Amazon / Flipkart / Paytm etc., will provide the data through API or flat file output in Excel / CSV format.

Exact Industry Requirement:

Most of the orders in Third party site will be having a combo product (combo product), if combo product is in order, we have two options

- Creation of Sales BOM and proceeding for PGI and Invoice.

- Creating a combo product through Production order by consuming components and output Materials will be a sale-able Item.

The industry opts for option 2. In this sales order requirement should flow through production order process.

Steps involved for this Automation:

Brief process flow as intro

Prerequisites to follow below mentioned steps:

Create a customer as onetime customer since industrial requirement does not have multiple customers for online sales (i.e., web/ e-comm sales). And check box of complete delivery should be enabled.

In order to have a control on Inventory activities, suggested to go ahead with single production order for a period (i.e., one Production Order for month) based on this all required output material will be created as co-product and output will be picked through 101 movement type.

Note: Though creation of production order also can be automated recommended creating production order manually since it’s a onetime activity.

- Orders received from third party website and downloaded to Excel or read through API provided by Service Provider.

- Consider this automated program basically executed through flat file, by reading flat file and this will create a Sales Order.

Since every Third-party site has unique format of output file upload, individual radio buttons been provided of user to select and upload the required Orders.

Validations are in place with Purchase order reference and Purchase order date reference to avoid duplicate Sales order upload.

- Sales order will be verified and triggered for second stage automation.

Verified Sales orders will be given as input to another program as follows for ease of approach program written with different performs based on activities.

START-OF-SELECTION.

*&---------- Reading Sales Order Data -------------------

PERFORM read_so_data.

*&---------- Inventory Check for Sales Order Qty --------

PERFORM inventory_check.

*&---------- Trans Post creation for L008 - L009 --------

PERFORM trans_post_suggestion.

*&---------- Migo of Trans. Posting ---------------------

PERFORM trans_post_posting.

*&----------- OBD / PGI --------------------------------

PERFORM obd_pgi.

*&----------- Invoice Posting --------------------------

PERFORM invoice_post.

And the selection screen for end user shown as follows :

here alternate plant is finding inventory available in alternate plant and proceed with Transfer posting for performing Production/pgi process for the execution plant.

All sales order document flow will be verified and validated before proceeding with OBD and Invoice.

- A sales order will be picked line item wise and inventory will be verified if inventory available then move to step 9.

SUBMIT rm07mlbs EXPORTING LIST TO MEMORY WITH matnr IN it_mat " Material Number

WITH werks EQ p_rplant " Plant

WITH bukrs EQ p_bukrs " Company Code

WITH kzlso EQ 'X' " Also Select Special Stocks

* WITH sobkz EQ 'E' "Special Stock Indicator

WITH kznul EQ 'X' " No zero stock lines

WITH mb52_noval EQ 'X' "Do not display values

WITH mb52_alv_flt EQ 'X' "Generate Non-Hierarchical List

AND RETURN.Wherever inventory check is required in this whole process call standard MB52 through submit and get the result and write required validations.

- If required inventory is not available, then as already said we have both Regular product (one finished good material) and combi product (having combination of multiple finished goods)

a) For regular product system will suggest for Transfer posting from existing Plant to required plant

CALL FUNCTION 'BAPI_GOODSMVT_CREATE'

EXPORTING

goodsmvt_header = wa_gmvt_header_tp

goodsmvt_code = *respective movement Code is required

* TESTRUN = ' '

* GOODSMVT_REF_EWM =

IMPORTING

goodsmvt_headret = gmvt_headret_tp

* MATERIALDOCUMENT = gmvt_retmtd

* MATDOCUMENTYEAR =

TABLES

goodsmvt_item = gmvt_item_tp[]

* GOODSMVT_SERIALNUMBER =

return = rt_bapiret_tp[]

* GOODSMVT_SERV_PART_DATA =

* EXTENSIONIN =

.b) For combi product – BOM will be explored and inventory will be verified if available push to next step, not available step 5) 1. will be triggered for the existing BOM components required quantity.

- Explore the BOM for the Combo product and checking the inventory for the components required for the Combo product.

SELECT z~matnr

z~werks

z~stlan

z~stlnr

v~idnrk

v~menge

v~meins FROM mast AS z

INNER JOIN stpo AS v ON v~stlnr EQ z~stlnr

INTO CORRESPONDING FIELDS OF TABLE it_mast

FOR ALL ENTRIES IN it_read_so_data

WHERE z~matnr EQ it_read_so_data-matnr

AND z~werks EQ it_read_so_data-werks

AND z~stlan EQ '1'.followed by this IT_MAST will have complete component list and required quantity for a sales order, before proceeding to production order Inventory check initiated and availability check executed.

- Required BOM quantity available in production plant then production order will be called, and output material will be identified in production order and updated with new required quantity or will be added as a new line item if it’s new material for that production order.

Through BAPI BAPI_PRODORD_GET_DETAIL production order will be read, and Finished goods will be added to prod. ord. as a co-product.

- Consumption entry of all component of a combi product will be posted with 261 movement type followed by this action GRN of Finished Goods will be proceed with 101 movement type.

Component for the above mentioned Finished Good added into the same prd.ord. followed by GRN consumption entry posted based on selection.

8. Repetition of step 4 for inventory check and proceed as mentioned.

based on availability flag end user can select the Sales order to proceed for OBD.

- OBD/PGI – BAPI to post the PGI called and committed followed by this Invoice posting and accounting entry posted.

List of all BAPI's and FM used to achieve above process :

Though most of the FM and BAPI's are known to most of the SAP consultants like to list for ease of understanding.

ALSM_EXCEL_TO_INTERNAL_TABLE - loading data from excel to internal table.

CS_BOM_EXPL_MAT_V2 - for BOM exploration.

BAPI_SALESORDER_CREATEFROMDAT2 - for Sales order creation with all condition types.

REUSE_ALV_POPUP_TO_SELECT - for all line selection option provided to users

BAPI_PRODORD_GET_DETAIL - for reading the production order data.

HR_JP_MONTH_BEGIN_END_DATE - to validate the production order in posting date's period.

CO_XT_COMPONENT_ADD - to add components to existing production order if the Finished goods are new to the production in the month. For both co-product or consumption product.

CO_XT_COMPONENT_CHANGE - this is to change the component which already present in the production order. For both co-product or consumption product.

BAPI_DELIVERYPROCESSING_EXEC & WS_DELIVERY_UPDATE - OBD/PGI positing after inventory check.

BAPI_BILLINGDOC_CREATEMULTIPLE - for the creating Invoice based on OBD/PGI

GUI_DOWNLOAD - Output / error file download to specified location for end user verification.

above listed BAPI's / FM is for present Industrial requirement, If industrial requirement is to create individual production for all Combo product or for any fresh regular finished goods through production order, which also can be addressed through production order creation BAPI, and Production order Post BAPI.

Conclusion:

Would like to conclude the above steps and functionality to achieve integration with real time challenges in this process automation are listed with the validation and implemented by futuristic thought of all statutory condition, inventory process, accounting entry, etc., further based on UAT and process flaws more number of validation may require to bring into the process as of now which ever considered as a requirements has been addressed and moved to production environment and given to users.

- SAP Managed Tags:

- MAN (Manufacturing),

- SD (Sales and Distribution),

- SD Sales

2 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Portfolio Management – Enhanced Financial Planning integration in Enterprise Resource Planning Blogs by SAP

- Enterprise Portfolio and Project Management in SAP S/4HANA Cloud, Private Edition 2023 FPS1 in Enterprise Resource Planning Blogs by SAP

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- Business Rule Framework Plus(BRF+) in Enterprise Resource Planning Blogs by Members

- SAP ERP Functionality for EDI Processing: UoMs Determination for Inbound Orders in Enterprise Resource Planning Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |