- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Cartonization planning in EWM for waves based on p...

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

flmarcilio

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

09-06-2019

6:07 PM

Purpose:

In shipping, cartonization is a process that evaluates items in an order to determine the number and size of each carton needed to ship the order.

In traditional packing environments, employees choose the boxes themselves or use order-fulfillment software to select the boxes. Cartonization automates and improves traditional manual shipping methods by saving money and reducing waste. For example, using cartonization can reduce the need to fill voids in boxes, result in less damage because goods are packed and shipped more efficiently and reduce overall shipping costs because packaging weights are reduced.

You can use cartonization planning to improve the creation of shipping handling units (HUs) based on information from product master data and outbound delivery orders, such as quantities, volume, and weight. Cartonization planning results in the creation of planned shipping handling units (PSHUs) that you can use as templates for creating shipping HUs during picking or packing

Overview:

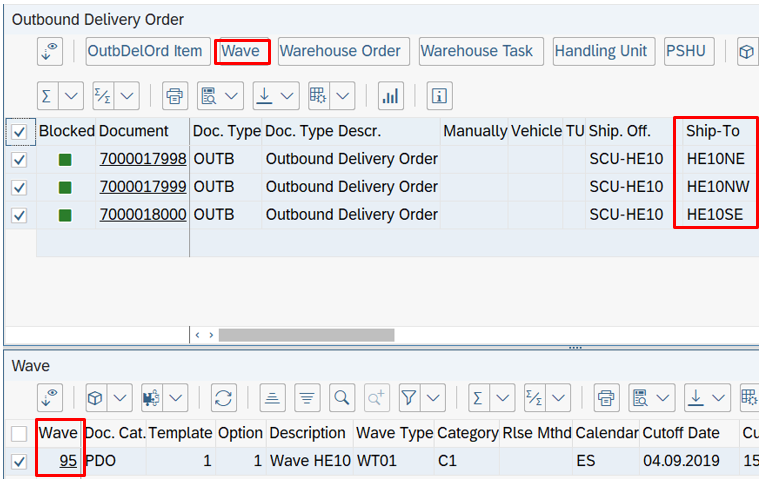

The scenario described below is covering three customers with the same route. There are also three products and three sizes of cartons which will be automatic defined according to the volume & weight capacity.

The EWM process steps starts with an automatic wave assignment based on the customer´s route as well as an outbound process oriented storage control with 2 steps (pick and pack).

Scenario 1:

- Customer HE10NE, products A,B and C with volume & weight capacity for large boxes.

Scenario 2:

- Customer HE10NW, products B and C with volume & weight capacity for medium boxes

Scenario 3:

- Customer HE10SE, product A with volume & weight capacity for small boxes

Step 1 : Customizing

Define package bulding profile

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define package bulding profile

Define number ranges for identification of PSHUs

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define number ranges for identification of PSHUs

Configure cartonization planning on warehouse number level

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Configure cartonization planning on warehouse number level

Define algorithm profiles for cartonization planning

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define algorithm profiles for cartonization planning

Define access sequence of algoriyhm profiles

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define access sequence of algoriyhm profiles

Define process profiles for cartonization planning

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define process profiles for cartonization planning

Note. This blog describe "Cartonization planning for waves"

Determine process profiles for cartonization planning

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Determine process profiles for cartonization planning

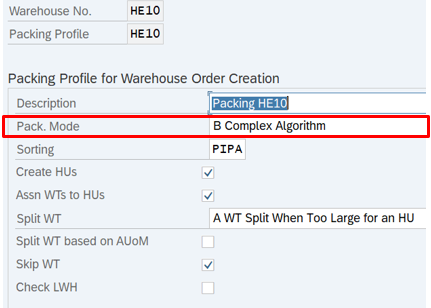

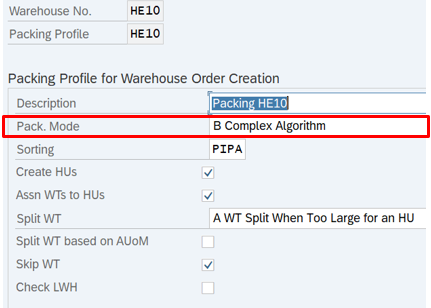

Define packing profile for warehouse order creation

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse order -> Define packing profile for warehouse order creation

Define creation rule for warehouse orders

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse order -> Define creation rule for warehouse orders

Define search sequence of creation rules for activity areas

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse order -> Define search sequence of creation rules for activity areas

Define process-oriented storage control

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Define process-oriented storage control

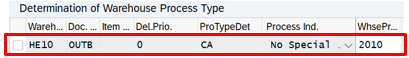

Define warehouse process type

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Define warehouse process type

Define control indicators for determining warehouse process types

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Define control indicators for determining warehouse process types

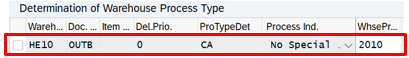

Determine warsehouse process type

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Determine warsehouse process type

Define work center

SPRO -> IMG -> EWM -> Mater data -> Work center -> Define work center

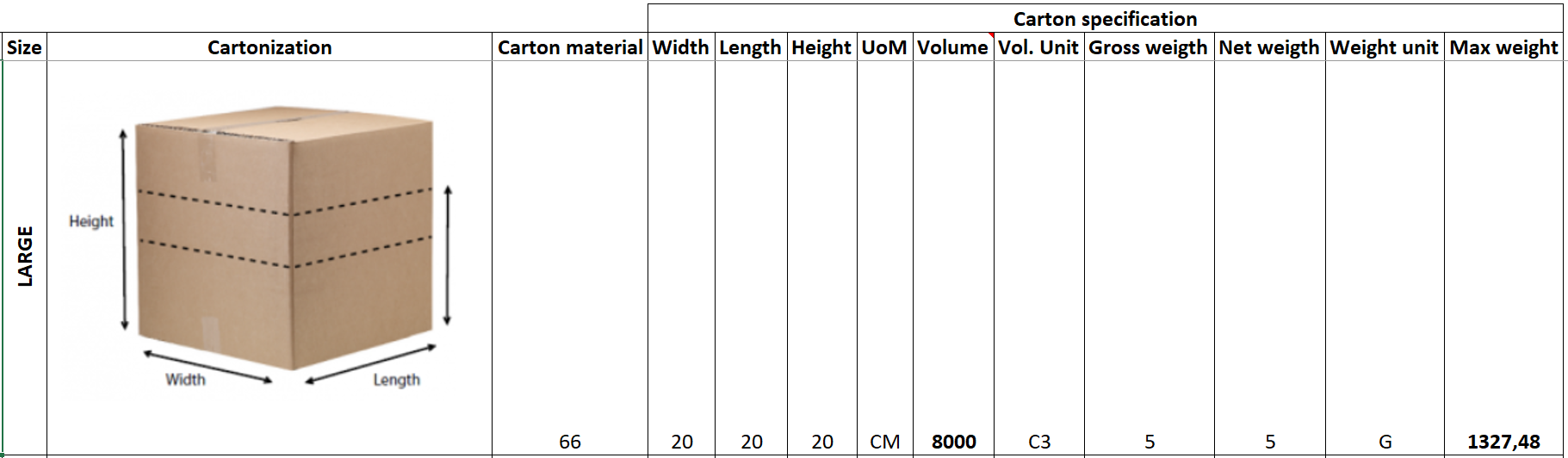

Step 2 : Master data

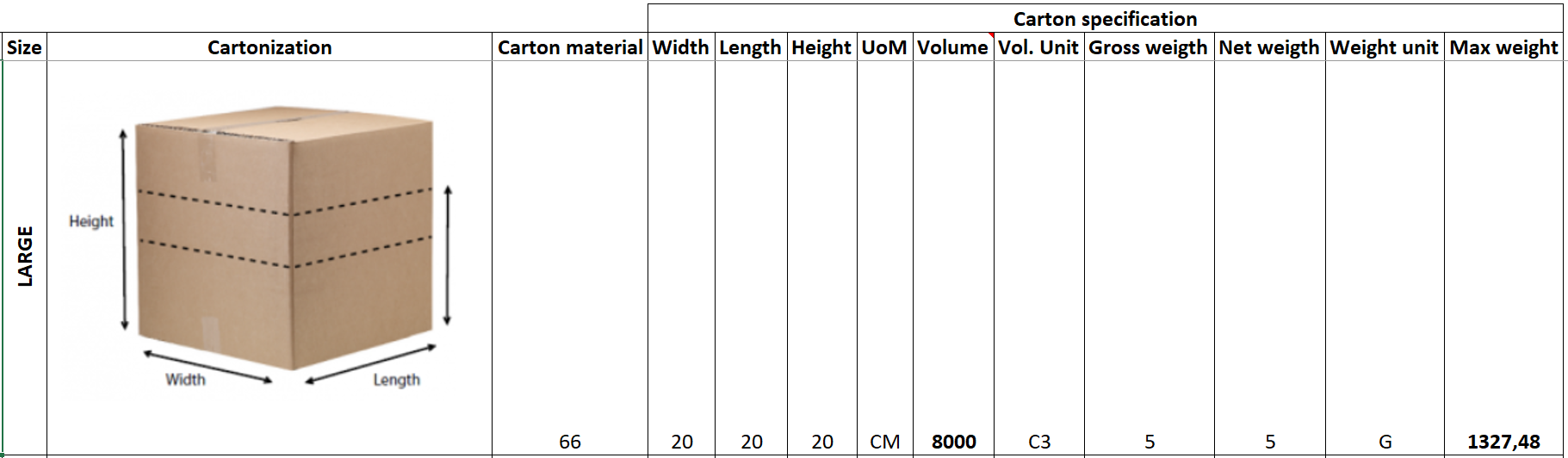

Maintain pack specification 3 times for each pack material described below.

t.code : /n/scwm/packspec

E.g. packspec “517“ assigned to pack material “66“

Determine algorithm profiles for cartonization planning

t.code : /n/scwm/cappdet

Assign start/end storage bin for activity area

t.code : /n/scwm/seba

Sort storage bins

t.code : /n/scwm/sbst

Maintain material master data

t.code : MM01 (ERP)

Maintain pack material (material type VERP)

t.code : MM01

Step 3 : E2E Process

Sales Order (ERP)

t.code : VA01

Outbound delivery (ERP)

t.code : VL02N

note. All of them is assigned to the same route.

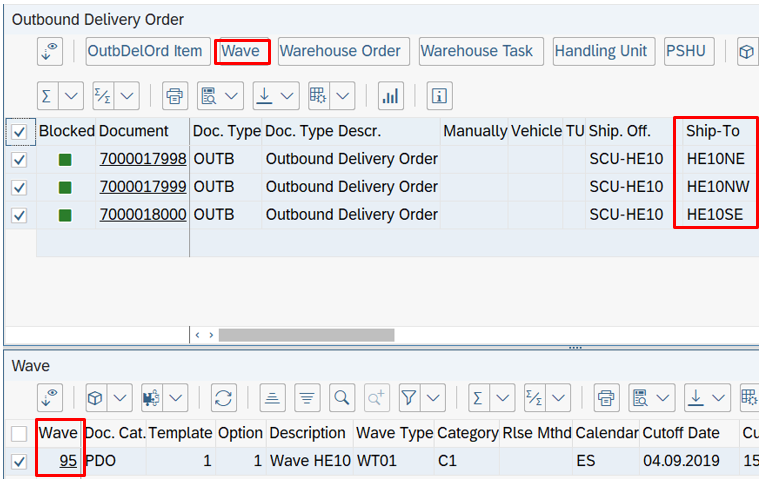

Automatic wave assignment

t.code : /n/scwm/mon

Cartonization planning for waves

t.code : /n/scwm/capwave

Note. You can also activate cartonization planning log, as follow:

Easy SAP menu -> EWM -> Settings -> Application log -> Active application log (/n/scwm/actlog)

Subobject : "CAP"

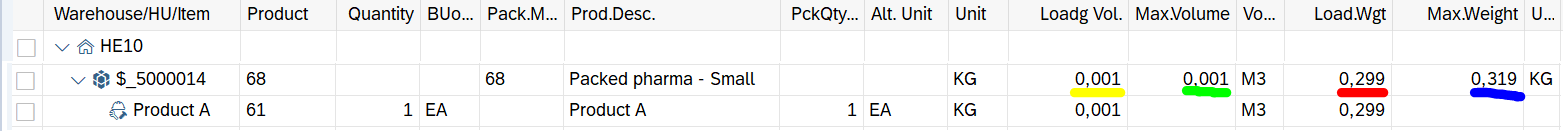

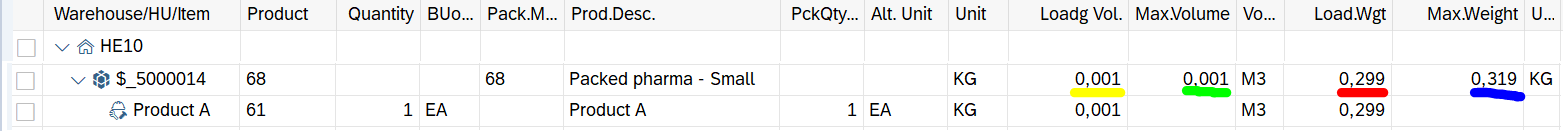

*** Cartonization planning results

T.code : /n/scwm/cap

Wave released and picking step (CAR1)

t.code : /n/scwm/mon

Packing step (CAR2)

t.code : /n/scwm/pack

Then, after the packing step it would follow the standard loading and goods issue processes.

References :

https://help.sap.com/saphelp_ewm900/helpdata/en/9a/9394774d164a4386c5a03124df9be4/frameset.htm

https://help.sap.com/saphelp_SCM700_ehp02/helpdata/en/36/17ca418c4e4bea96b304726d94231f/content.htm?...

https://searcherp.techtarget.com/definition/cartonization

In shipping, cartonization is a process that evaluates items in an order to determine the number and size of each carton needed to ship the order.

In traditional packing environments, employees choose the boxes themselves or use order-fulfillment software to select the boxes. Cartonization automates and improves traditional manual shipping methods by saving money and reducing waste. For example, using cartonization can reduce the need to fill voids in boxes, result in less damage because goods are packed and shipped more efficiently and reduce overall shipping costs because packaging weights are reduced.

You can use cartonization planning to improve the creation of shipping handling units (HUs) based on information from product master data and outbound delivery orders, such as quantities, volume, and weight. Cartonization planning results in the creation of planned shipping handling units (PSHUs) that you can use as templates for creating shipping HUs during picking or packing

Overview:

The scenario described below is covering three customers with the same route. There are also three products and three sizes of cartons which will be automatic defined according to the volume & weight capacity.

The EWM process steps starts with an automatic wave assignment based on the customer´s route as well as an outbound process oriented storage control with 2 steps (pick and pack).

Scenario 1:

- Customer HE10NE, products A,B and C with volume & weight capacity for large boxes.

Scenario 2:

- Customer HE10NW, products B and C with volume & weight capacity for medium boxes

Scenario 3:

- Customer HE10SE, product A with volume & weight capacity for small boxes

Step 1 : Customizing

Define package bulding profile

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define package bulding profile

Define number ranges for identification of PSHUs

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define number ranges for identification of PSHUs

Configure cartonization planning on warehouse number level

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Configure cartonization planning on warehouse number level

Define algorithm profiles for cartonization planning

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define algorithm profiles for cartonization planning

Define access sequence of algoriyhm profiles

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define access sequence of algoriyhm profiles

Define process profiles for cartonization planning

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define process profiles for cartonization planning

Note. This blog describe "Cartonization planning for waves"

Determine process profiles for cartonization planning

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Determine process profiles for cartonization planning

Define packing profile for warehouse order creation

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse order -> Define packing profile for warehouse order creation

Define creation rule for warehouse orders

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse order -> Define creation rule for warehouse orders

Define search sequence of creation rules for activity areas

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse order -> Define search sequence of creation rules for activity areas

Define process-oriented storage control

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Define process-oriented storage control

Define warehouse process type

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Define warehouse process type

Define control indicators for determining warehouse process types

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Define control indicators for determining warehouse process types

Determine warsehouse process type

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Determine warsehouse process type

Define work center

SPRO -> IMG -> EWM -> Mater data -> Work center -> Define work center

Step 2 : Master data

Maintain pack specification 3 times for each pack material described below.

- Material “66“ – cartonization large

- Material “67“ – cartonization medium

- Material “68“ – cartonization small

t.code : /n/scwm/packspec

E.g. packspec “517“ assigned to pack material “66“

Determine algorithm profiles for cartonization planning

t.code : /n/scwm/cappdet

Assign start/end storage bin for activity area

t.code : /n/scwm/seba

Sort storage bins

t.code : /n/scwm/sbst

Maintain material master data

t.code : MM01 (ERP)

- “Product A“

- “Product B“

- “Product C“

Maintain pack material (material type VERP)

t.code : MM01

- “ Packed pharma - Large“

- “ Packed pharma - Medium“

- “ Packed pharma - Small“

Step 3 : E2E Process

Sales Order (ERP)

t.code : VA01

Outbound delivery (ERP)

t.code : VL02N

note. All of them is assigned to the same route.

Automatic wave assignment

t.code : /n/scwm/mon

Cartonization planning for waves

t.code : /n/scwm/capwave

Note. You can also activate cartonization planning log, as follow:

Easy SAP menu -> EWM -> Settings -> Application log -> Active application log (/n/scwm/actlog)

Subobject : "CAP"

*** Cartonization planning results

T.code : /n/scwm/cap

Wave released and picking step (CAR1)

t.code : /n/scwm/mon

Packing step (CAR2)

t.code : /n/scwm/pack

Then, after the packing step it would follow the standard loading and goods issue processes.

References :

https://help.sap.com/saphelp_ewm900/helpdata/en/9a/9394774d164a4386c5a03124df9be4/frameset.htm

https://help.sap.com/saphelp_SCM700_ehp02/helpdata/en/36/17ca418c4e4bea96b304726d94231f/content.htm?...

https://searcherp.techtarget.com/definition/cartonization

- SAP Managed Tags:

- EWM - Delivery Processing

5 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

New Feature

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4 HANA 2022

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP TM

1 -

SAP Transportation Management

3 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- « Previous

- Next »

Related Content

- The Benefits of Applying Semantic Visions’ Screening and Monitoring Services in Supply Chain Management Blogs by Members

- AI-Based Scheduling in SAP Field Service Management in Supply Chain Management Blogs by SAP

- Unlock your supply chain potential with SAP Integrated Business Planning AI in Supply Chain Management Blogs by SAP

- Displaying Best Fit Forecast Algorithm in Planning View in Supply Chain Management Blogs by Members

- ABC of SAP IBP Licensing in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 4 | |

| 4 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |