- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- iPPE- implementation considerations in S/4 HANA

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

KrishnaPrasadKa

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

08-27-2019

9:53 AM

iPPE is a specialized master data, but less explored unlike other master data in SAP. iPPE functionality was available in ECC and its integration with APO. iPPE functionality is also available in S/4 HANA and can be used with PPDS in S/4 HANA.

iPPE in S/4HANA is available as standard solution and does not require any additional activation or license. However if iPPE is used with PPDS then activation of PPDS requires separate license in S/4 HANA.

Even though certain transactions in iPPE has been removed (Refer SAP note 2226431) as a part of simplifications in S/4 HANA, almost all functionality of iPPE (in both ECC and APO) is still available in S/4 HANA.

Application of iPPE:

iPPE(integrated Product and Process Engineering) is meant for highly variable products.

iPPE is mostly used in automotive industries, where from product design concept, till production execution process can be integrated using iPPE data. In case of model-mix planning & Rapid Planning Matrix(RPM) in APO-PPDS or S/4HANA PPDS, iPPE is mandatory.

Overview

iPPE supports both Configurable(KMAT) material and Material Variant. Hence Variant Configuration data is required to setup iPPE. iPPE also supports change management. In case of complex configuration especially in automotive sectors, iPPE is recommended.

Components of iPPE

iPPE typically consists of below objects.

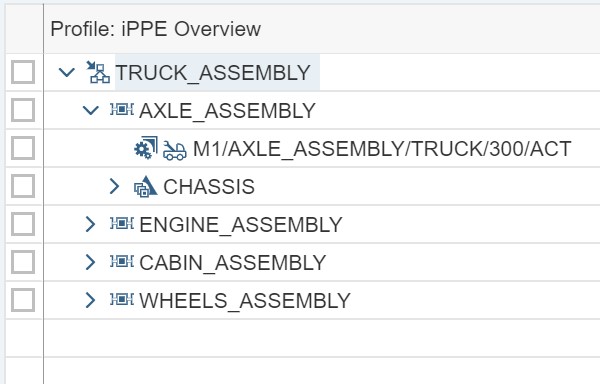

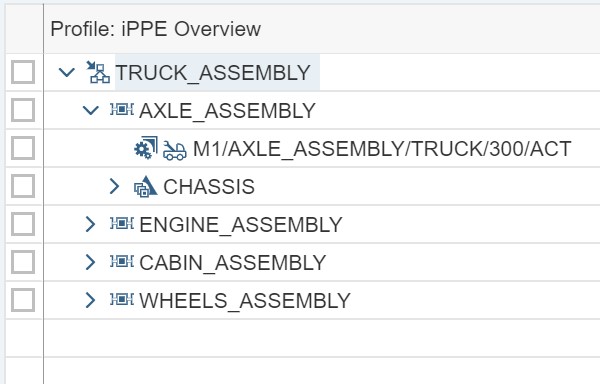

Product Structure:

Typical product structure consists of Access node, Structure node & Assembly.

iPPE also supports other nodes such as color node and PVS. Refer SAP help for more details

https://help.sap.com/viewer/2b37de3188714044ae00efda7583a428/1709%20000/en-US/ce09c4530b29b44ce10000...

Process Structure:

Typical product structure consists of Routing Header & Activity.

iPPE also supports other nodes such as grouping activities or operations. Refer SAP help for more details

https://help.sap.com/viewer/2b37de3188714044ae00efda7583a428/1709%20000/en-US/46f5c353fad0b44ce10000...

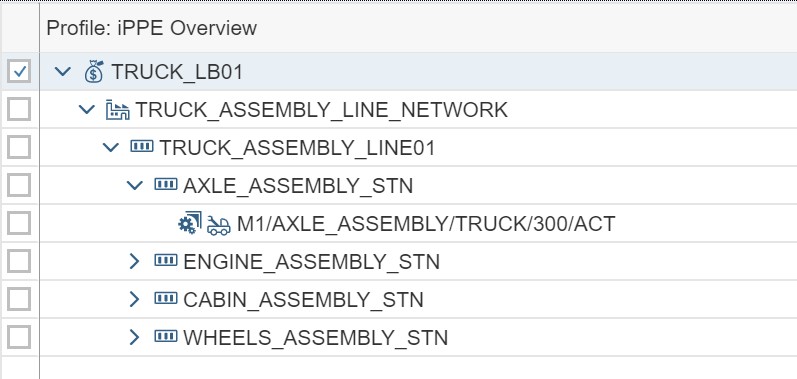

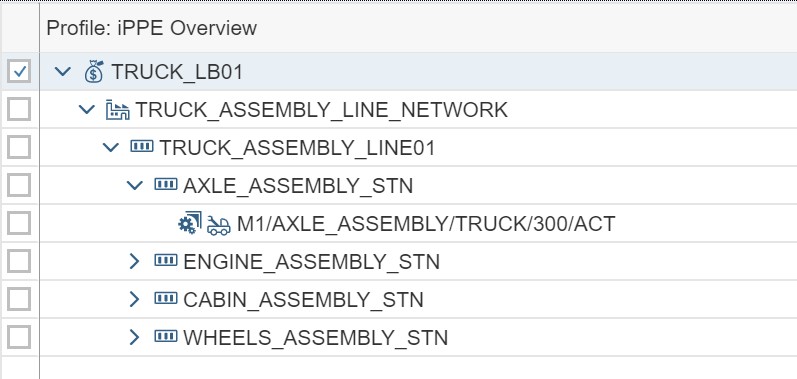

Factory Layout:

Typical product structure consists of Line Network, Line and Line Segments.

iPPE also supports other nodes such as Line Area, Work Area and Buffers. Refer SAP help for more details

https://help.sap.com/viewer/2b37de3188714044ae00efda7583a428/1709%20000/en-US/c809c4530b29b44ce10000...

Components of iPPE (product structure, Process Structure and Factory Layout) is integrated by line balance, which helps in calculating the Takt time at each stage of production in an assembly line.

Refer SAP help for more details on line balance and Takt based scheduling.

https://help.sap.com/viewer/2b37de3188714044ae00efda7583a428/1709%20000/en-US/759ec453f57eb44ce10000...

Integration of iPPE with Warehouse management data.

iPPE supports IM/WM or EWM location to be used as receiving location in production version. However if S2L(Automatic Supply-to-production) process is used with integration of PPDS, then limitations of EWM & PPDS does apply for JIT. Refer SAP note 2492542.

Integration of iPPE with PPDS(in S/4 HANA)

iPPE master data created in S/4 HANA has to be transferred to PPDS as PDS in order to be used in PPDS planning such as model-mix planning.

However before transferring data, certain prerequisites needs to be ensured such as

Once iPPE production version is created in S/4 HANA, iPPE data has to be transferred to PPDS using the transaction PPEAPO. This will create iPPE data in PPDS in S/4 HANA and necessary line resource as mentioned in iPPE line.

It is necessary to run consistency check report to evaluate and fix the errors in iPPE before creating the PDS.

Further PDS in PPDS is can be created using transaction code /SAPAPO/GEN_PDS. This PDS is used for planning in PPDS using model-mix planning applications.

Advantages of iPPE:

In general, iPPE can be used for both MTS and MTO scenarios. Even though iPPE+PPDS is more generally used for REM, since PPDS supports REM execution. Which gives complete end-to-end functionality for Automotive OEMs.

iPPE is a better solution comparing with typical Variant Configuration BOM in S/4HANA(or ECC) especially in case of highly configurable products with high volumes.

References:

iPPE - https://help.sap.com/viewer/f899ce30af9044299d573ea30b533f1c/1809.002/en-US/66160651de86d406e1000000...

PP/DS REM - https://help.sap.com/viewer/f899ce30af9044299d573ea30b533f1c/1809.002/en-US/d630f9504a62eb5ee1000000...

iPPE in S/4HANA is available as standard solution and does not require any additional activation or license. However if iPPE is used with PPDS then activation of PPDS requires separate license in S/4 HANA.

Even though certain transactions in iPPE has been removed (Refer SAP note 2226431) as a part of simplifications in S/4 HANA, almost all functionality of iPPE (in both ECC and APO) is still available in S/4 HANA.

Application of iPPE:

iPPE(integrated Product and Process Engineering) is meant for highly variable products.

iPPE is mostly used in automotive industries, where from product design concept, till production execution process can be integrated using iPPE data. In case of model-mix planning & Rapid Planning Matrix(RPM) in APO-PPDS or S/4HANA PPDS, iPPE is mandatory.

Overview

iPPE supports both Configurable(KMAT) material and Material Variant. Hence Variant Configuration data is required to setup iPPE. iPPE also supports change management. In case of complex configuration especially in automotive sectors, iPPE is recommended.

Components of iPPE

iPPE typically consists of below objects.

Product Structure:

Typical product structure consists of Access node, Structure node & Assembly.

iPPE also supports other nodes such as color node and PVS. Refer SAP help for more details

https://help.sap.com/viewer/2b37de3188714044ae00efda7583a428/1709%20000/en-US/ce09c4530b29b44ce10000...

Process Structure:

Typical product structure consists of Routing Header & Activity.

iPPE also supports other nodes such as grouping activities or operations. Refer SAP help for more details

https://help.sap.com/viewer/2b37de3188714044ae00efda7583a428/1709%20000/en-US/46f5c353fad0b44ce10000...

Factory Layout:

Typical product structure consists of Line Network, Line and Line Segments.

iPPE also supports other nodes such as Line Area, Work Area and Buffers. Refer SAP help for more details

https://help.sap.com/viewer/2b37de3188714044ae00efda7583a428/1709%20000/en-US/c809c4530b29b44ce10000...

Components of iPPE (product structure, Process Structure and Factory Layout) is integrated by line balance, which helps in calculating the Takt time at each stage of production in an assembly line.

Refer SAP help for more details on line balance and Takt based scheduling.

https://help.sap.com/viewer/2b37de3188714044ae00efda7583a428/1709%20000/en-US/759ec453f57eb44ce10000...

Integration of iPPE with Warehouse management data.

iPPE supports IM/WM or EWM location to be used as receiving location in production version. However if S2L(Automatic Supply-to-production) process is used with integration of PPDS, then limitations of EWM & PPDS does apply for JIT. Refer SAP note 2492542.

Integration of iPPE with PPDS(in S/4 HANA)

iPPE master data created in S/4 HANA has to be transferred to PPDS as PDS in order to be used in PPDS planning such as model-mix planning.

However before transferring data, certain prerequisites needs to be ensured such as

- CIF Change pointer for message type “CIF_PPE_PRM” is activated using BD50.

- Supply areas used need to be integrated to PPDS.

- All material master which needs to be planned using PPDS, needs to be set with ‘Advanced Planning’ flag. However it is also possible plan higher level material masters in PPDS, and keeping lower assembly planning with MRP in S/4 HANA.

- In S/4 PPDS the iPPE integration model is not needed any longer. Hence CFM1 & CFM2 is not required.

Once iPPE production version is created in S/4 HANA, iPPE data has to be transferred to PPDS using the transaction PPEAPO. This will create iPPE data in PPDS in S/4 HANA and necessary line resource as mentioned in iPPE line.

It is necessary to run consistency check report to evaluate and fix the errors in iPPE before creating the PDS.

Further PDS in PPDS is can be created using transaction code /SAPAPO/GEN_PDS. This PDS is used for planning in PPDS using model-mix planning applications.

Advantages of iPPE:

In general, iPPE can be used for both MTS and MTO scenarios. Even though iPPE+PPDS is more generally used for REM, since PPDS supports REM execution. Which gives complete end-to-end functionality for Automotive OEMs.

iPPE is a better solution comparing with typical Variant Configuration BOM in S/4HANA(or ECC) especially in case of highly configurable products with high volumes.

References:

iPPE - https://help.sap.com/viewer/f899ce30af9044299d573ea30b533f1c/1809.002/en-US/66160651de86d406e1000000...

PP/DS REM - https://help.sap.com/viewer/f899ce30af9044299d573ea30b533f1c/1809.002/en-US/d630f9504a62eb5ee1000000...

- SAP Managed Tags:

- SAP S/4HANA,

- SCM APO Production Planning and Detailed Scheduling (PP/DS)

12 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Manage Supply Shortage and Excess Supply with MRP Material Coverage Apps in Enterprise Resource Planning Blogs by SAP

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- AMDP – Error with Customer Namespaces and joined CDS View with Parameters in Enterprise Resource Planning Q&A

- FAQ on Upgrading SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Blogs by SAP

- FAQ: S/4HANA Cloud, public edition - Sales in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |