- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Embedded IoT in Business Processes: SAP Leonardo I...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member25

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

07-17-2019

9:00 AM

Summary

SAP C/4HANA Field Service Management (FSM) optimise scheduling, planning, and dispatching in real time with AI-based tools. It manages and automates comprehensive field service processes, including service order planning, resource scheduling, on-site service execution, and billing. It offers the network of field engineers, mobile access to information to increase productivity.

This blog post will give details about IoT Embedded C/4 Field Service Management (FSM), its benefits, scenarios where it is helpful and process steps to achieve the same using SAP Leonardo IOT.

Example Scenario

Let us consider a scenario where a company, Robofabric Inc., manufacturers industrial robots. Their popular models are Robot4000 and Robot4100. These are special self-driving and self-charging robots to move components from one section of an industrial plant to the other. Following are the robot models:

Robofabric Inc has multiple customers worldwide that use these robots on a daily basis and in North America alone they have more than 45 customers that have bought more than 10000 such robots.

As a special agreement Robofabric Inc has extended service level agreements with several of its customers to ensure timely repair and maintenance of these robots, so that there is minimal downtime.

Let us consider a scenario where Robofabric has installed Field Service Management (FSM) to monitor and track Service calls and following issue occurs with one of its customers.

Say, there is a power issue with a robot of model type Robot4100 and it stops working.

At this point, customer calls Robofabric to inform about the malfunctioning robot. The Robofabric executive creates a service call and assigns it to a Field Engineer. The field engineer can access the services calls assigned to him/her via a mobile application (as shown below).

The assigned field technician does not know what exactly happened with the device (robot). He/she will travel to the site, have a look and will try to repair or come back to base work station to collect some parts and again go to try fixing the issue. In this particular scenario, the field technician realizes that there is a problem with the battery. He/she then makes another trip to collect the spares and then returns to fix the issue. Hence, this involved multiple trips for the field technician and issue resolution took more time which lead to loss of business hours for all those who were involved. This impacts customer satisfaction as well.

Scenario: IoT embedded Field Services Management

Let us consider if Robofarbic implements IOT along with C/4 HANA Field Service Management for service execution capabilities. They first connect relevant sensors to the robots and use SAP Leonardo IoT to collect IoT data from the connected robots. The sensors present on the robots are the battery temperature monitoring sensor and the battery level indicator.

Now customer’s robots are connected, and users can monitor key operational parameters at real time. Rules are configured to detect anomalies early to provide proactive service.

Let us consider same scenario (sudden decrease in voltage in Robot4100 at a customer).

Based on the configured rules, a Service call that would be created automatically in C/4 Field Service Management is then assigned to a field technician. This is where IoT plays a vital role. The field technician now has contextual data from IoT (illustrated in screenshots below). He/she can view KPIs and important historical time series data. He/she can also see a list of events that occurred which led to the failure. This enables the field technician to be prepared before he/she visits the customer.

Equipped with IoT data, the field technician already knows the reasons for robot failure. He/she can be prepared before visiting the customer. Not only does this reduce the number of trips a field technician makes (and consequently costs), it also improves customer satisfaction.

Process Steps in Leonardo IOT

This is the layer at which devices are registered, known as Onboarding.

Data is received from onboarded things.

Data is monitored and analysed for critical parameters like severe decrease in voltage when powered on.

Events can be generated as and when rules get triggered. These events can be used for integration scenarios with third party solutions.

Actions can be configured based to generate notifications, events and service calls through Service Integration Options.

Let us consider our scenario again to understand this layer.

We use Master data artefacts like Business Partner and Equipment in this scenario. Service call creation also require Business Partner assigned to that Equipment and this has been handled through IFlow(CPI) while creating Service Call.

In order to rectify the issues with respective equipment, a technician might require more information of the equipment data which is maintained in Leonardo IoT. This information can help him/her in understanding the frequent issues for the selected equipment and help him/her to speed up in providing solution as early as possible. This can be achieved by building an HTML5 application that visualizes IoT data and the same can be embedded into FSM Mobile Application using Web Containers Concept.

A sample code to realize parts of the C/4 FSM embedded scenario using SAP Leonardo IoT is published in the following GitHub (https://github.com/SAP-samples/leonardo-iot-c4fsm). This sample code can be used to quickly configure the scenario in SAP Leonardo IoT and further extended. The sample code focuses on thing modelling, custom master data, UI for data visualization, rules and automated creation of service calls.

Conclusion

Manufacturers need to adequately react to a customer call for service. Today customers demand more as they understand that equipment data is available with the manufacturer to provide proactive service in advance that ensures 24*7 operations of the equipment. Since IoT data is continuously collected from every deployed equipment centrally in the SAP Leonardo IoT Cloud to automatically create service calls in advance when anomalies are detected, this leads to increased customer satisfaction. Also, it provides technicians mobile access to faulty equipment data, hence it enables them to proactively monitor and be equipped to solve the issue even before reaching field.

SAP C/4HANA Field Service Management (FSM) optimise scheduling, planning, and dispatching in real time with AI-based tools. It manages and automates comprehensive field service processes, including service order planning, resource scheduling, on-site service execution, and billing. It offers the network of field engineers, mobile access to information to increase productivity.

This blog post will give details about IoT Embedded C/4 Field Service Management (FSM), its benefits, scenarios where it is helpful and process steps to achieve the same using SAP Leonardo IOT.

Example Scenario

Let us consider a scenario where a company, Robofabric Inc., manufacturers industrial robots. Their popular models are Robot4000 and Robot4100. These are special self-driving and self-charging robots to move components from one section of an industrial plant to the other. Following are the robot models:

- Robot4000: basic model that comes with only one power source – Main Battery.

- Robot4100: Is the advanced model that comes with 2 battery packs- Main Battery that powers the main components, and Auxiliary Battery that power the extra extended arm.

Robofabric Inc has multiple customers worldwide that use these robots on a daily basis and in North America alone they have more than 45 customers that have bought more than 10000 such robots.

As a special agreement Robofabric Inc has extended service level agreements with several of its customers to ensure timely repair and maintenance of these robots, so that there is minimal downtime.

Let us consider a scenario where Robofabric has installed Field Service Management (FSM) to monitor and track Service calls and following issue occurs with one of its customers.

Say, there is a power issue with a robot of model type Robot4100 and it stops working.

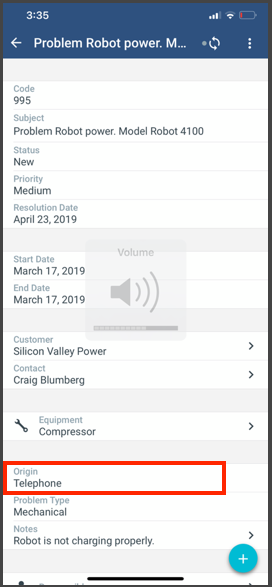

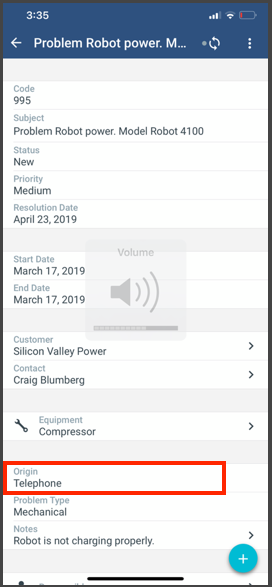

At this point, customer calls Robofabric to inform about the malfunctioning robot. The Robofabric executive creates a service call and assigns it to a Field Engineer. The field engineer can access the services calls assigned to him/her via a mobile application (as shown below).

The assigned field technician does not know what exactly happened with the device (robot). He/she will travel to the site, have a look and will try to repair or come back to base work station to collect some parts and again go to try fixing the issue. In this particular scenario, the field technician realizes that there is a problem with the battery. He/she then makes another trip to collect the spares and then returns to fix the issue. Hence, this involved multiple trips for the field technician and issue resolution took more time which lead to loss of business hours for all those who were involved. This impacts customer satisfaction as well.

Scenario: IoT embedded Field Services Management

Let us consider if Robofarbic implements IOT along with C/4 HANA Field Service Management for service execution capabilities. They first connect relevant sensors to the robots and use SAP Leonardo IoT to collect IoT data from the connected robots. The sensors present on the robots are the battery temperature monitoring sensor and the battery level indicator.

Now customer’s robots are connected, and users can monitor key operational parameters at real time. Rules are configured to detect anomalies early to provide proactive service.

Let us consider same scenario (sudden decrease in voltage in Robot4100 at a customer).

Based on the configured rules, a Service call that would be created automatically in C/4 Field Service Management is then assigned to a field technician. This is where IoT plays a vital role. The field technician now has contextual data from IoT (illustrated in screenshots below). He/she can view KPIs and important historical time series data. He/she can also see a list of events that occurred which led to the failure. This enables the field technician to be prepared before he/she visits the customer.

- Service call is created (the source here is IoT – which means that the service call was automatically created via IoT)

- Notes tab which gives summary of the issue.

- Below shown option – Equipment Data (can be any other name depending on what the user wants to call it), can be used by the field technician to view IoT data.

- Basic and critical parameters that the field technicians can visualize. This includes details that can be used to identify the device, sensor data, and event data. The event data here clearly shows that the battery temperature first reached critical levels, which then led to battery failure (sudden reduction in voltage).

Equipped with IoT data, the field technician already knows the reasons for robot failure. He/she can be prepared before visiting the customer. Not only does this reduce the number of trips a field technician makes (and consequently costs), it also improves customer satisfaction.

Process Steps in Leonardo IOT

- Product Registration

This is the layer at which devices are registered, known as Onboarding.

- Sensor data from Onboarded Things

Data is received from onboarded things.

- Rules on Time Series Data

Data is monitored and analysed for critical parameters like severe decrease in voltage when powered on.

- Event

Events can be generated as and when rules get triggered. These events can be used for integration scenarios with third party solutions.

- Action

Actions can be configured based to generate notifications, events and service calls through Service Integration Options.

- CPI: Cloud Platform Integrator

Let us consider our scenario again to understand this layer.

- It extracts equipment ID for which there is a sudden decrease in Voltage.

- It also extracts BP using Equipment Id for a particular Equipment.

- Checks system if Service Call already exists in Open status for the respective problem type

- If there is no Service call already, then it creates Service Call by calling FSM APIs.

- C4 FSM Backend

We use Master data artefacts like Business Partner and Equipment in this scenario. Service call creation also require Business Partner assigned to that Equipment and this has been handled through IFlow(CPI) while creating Service Call.

- Embedding IoT Content in FSM Mobile Application

In order to rectify the issues with respective equipment, a technician might require more information of the equipment data which is maintained in Leonardo IoT. This information can help him/her in understanding the frequent issues for the selected equipment and help him/her to speed up in providing solution as early as possible. This can be achieved by building an HTML5 application that visualizes IoT data and the same can be embedded into FSM Mobile Application using Web Containers Concept.

A sample code to realize parts of the C/4 FSM embedded scenario using SAP Leonardo IoT is published in the following GitHub (https://github.com/SAP-samples/leonardo-iot-c4fsm). This sample code can be used to quickly configure the scenario in SAP Leonardo IoT and further extended. The sample code focuses on thing modelling, custom master data, UI for data visualization, rules and automated creation of service calls.

Conclusion

Manufacturers need to adequately react to a customer call for service. Today customers demand more as they understand that equipment data is available with the manufacturer to provide proactive service in advance that ensures 24*7 operations of the equipment. Since IoT data is continuously collected from every deployed equipment centrally in the SAP Leonardo IoT Cloud to automatically create service calls in advance when anomalies are detected, this leads to increased customer satisfaction. Also, it provides technicians mobile access to faulty equipment data, hence it enables them to proactively monitor and be equipped to solve the issue even before reaching field.

- SAP Managed Tags:

- SAP Internet of Things,

- Customer Experience,

- Internet of Things

Labels:

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

38 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

66 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- SAP Named a Leader in the 2024 Gartner Magic Quadrant for Transportation Management Systems in Supply Chain Management Blogs by SAP

- Preferred Alternative UoM for Warehouse Operation in EWM in Supply Chain Management Blogs by Members

- Adverse Media Monitoring: How to improve overall Supply Chain Management in Supply Chain Management Blogs by Members

- Announcement: New integration platform in SAP Business Network for Logistics in Supply Chain Management Blogs by SAP

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 9 | |

| 8 | |

| 5 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |