- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Monday Knowledge Snippet (MKS) – 88 Detailed Packa...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member18

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

04-15-2019

7:45 AM

One important aspect of detailed package building is the consideration of product (group) stacking constraints. For the definitions it is possible to distinguish between settings that restrict the behavior for a single product (group) and settings restricting product (group) relations when combining them. So far the Supply Chain Execution Package Builder (SCE PB) did only support stacking factors (see MKS77) covering the single product (group) settings. As soon as product combinations come into play, it can get complicated pretty quickly. Basically such settings tell the Package Building Optimizer how to handle heterogeneous product sets. What can be on top of something else? What not? What are the tolerances when some space is required (non-flat stacking, overhang)?

When designing a solution for this, we had in mind to support easy-to-define, but yet powerful constraints. This means:

As a consequence, the definitions are spread over multiple spots.

Package Building Profile

The package building profile has been enhanced with 2 new settings. The 'Stacking Sequence' allows to switch the priority between density and weight. The 'Stable Overhang Threshold [%]' enables to define the tolerance when an item can only be stacked when a certain overhang is required.

Product Definitions

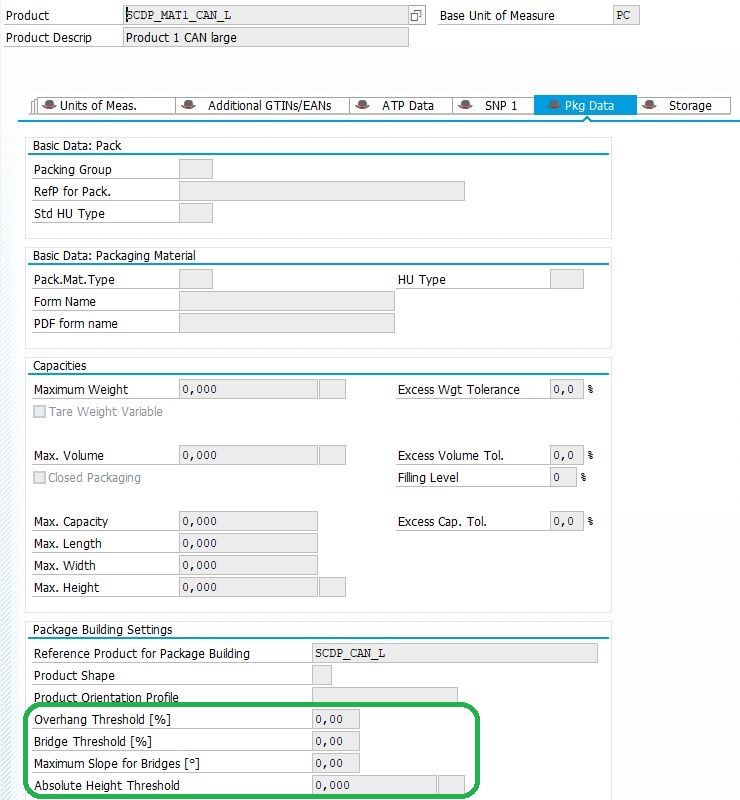

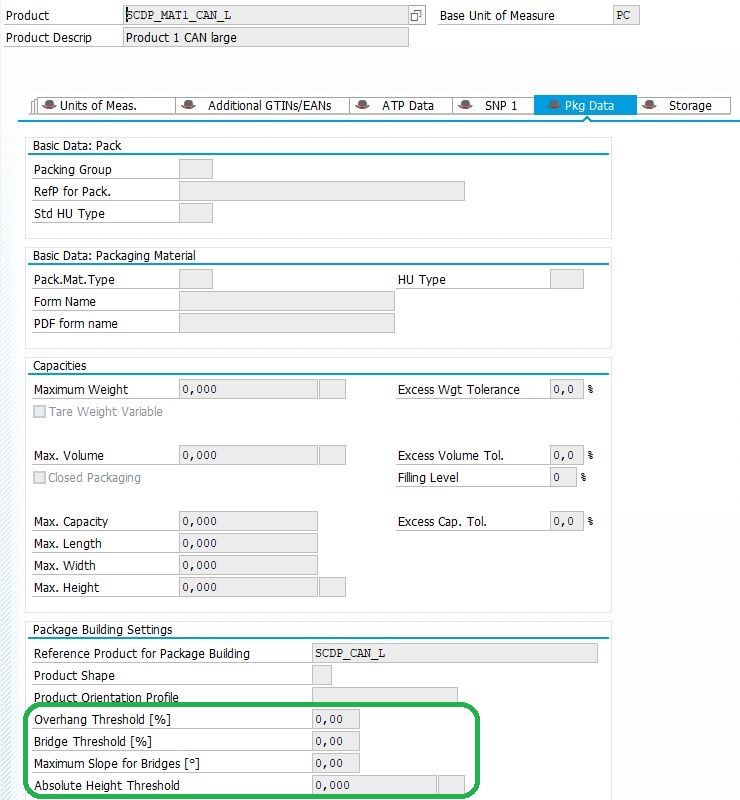

In the product master the packaging data has been enhanced with Package Building Settings. There new settings for overhang, bridge, and non-flat stacking can be found.

In the S4 version, the packaging definitions can be found under 'WM Packaging':

Product Relationship Profile

The final spot for definitions is the new Product Relationship Profile offering stacking settings. Here it is possible to define which product (group) can be on top of another. Note that settings here should only be made in case they are not covered by the Stacking Sequence in the package building profile.

To make it a bit more transparent how the definitions are used by the PBO, I would like to explain the use cases.

What is non-flat stacking?

Depending on the product dimensions, it is possible that a mixed layer forms a non-flat area on top. If no tolerance would be allowed when trying to put something on top, only smaller items could fit.

Default behavior is that no non-flat stacking is allowed.

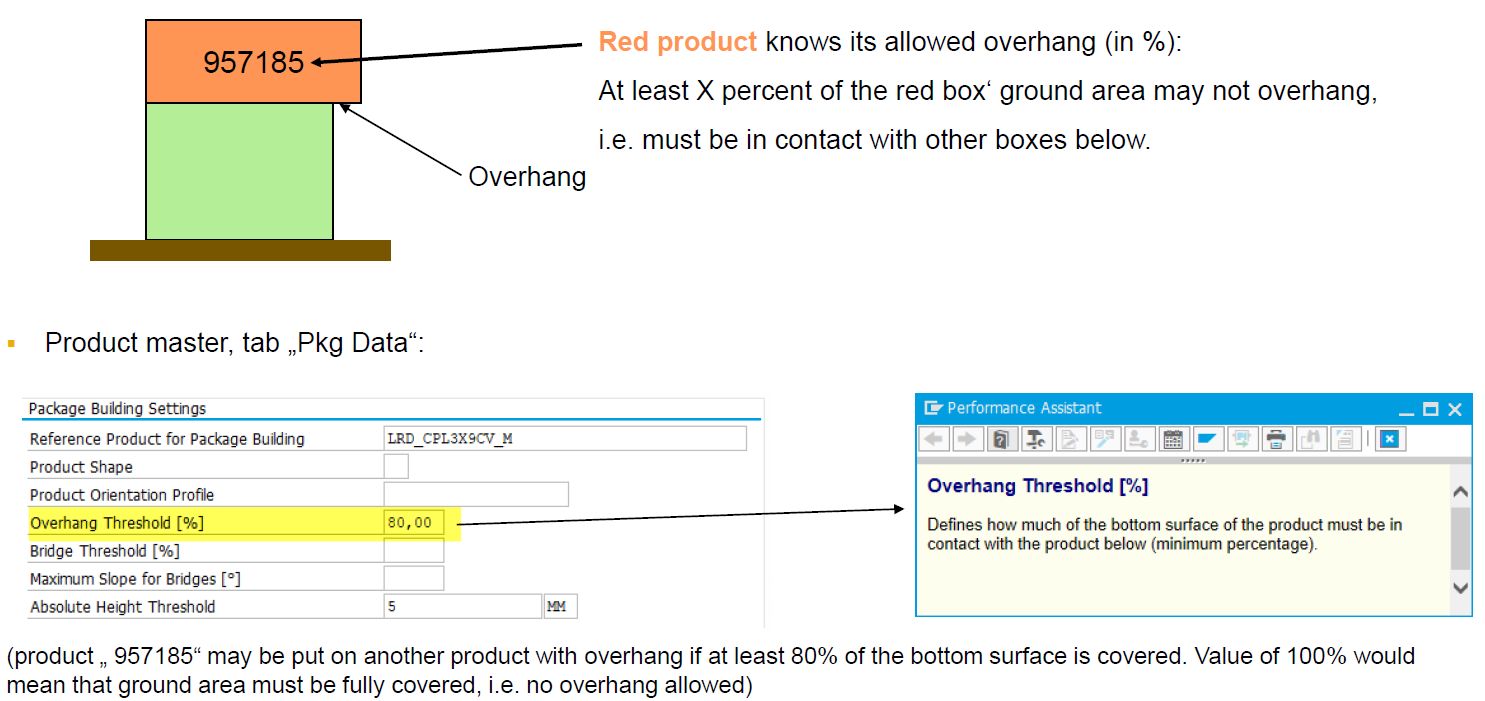

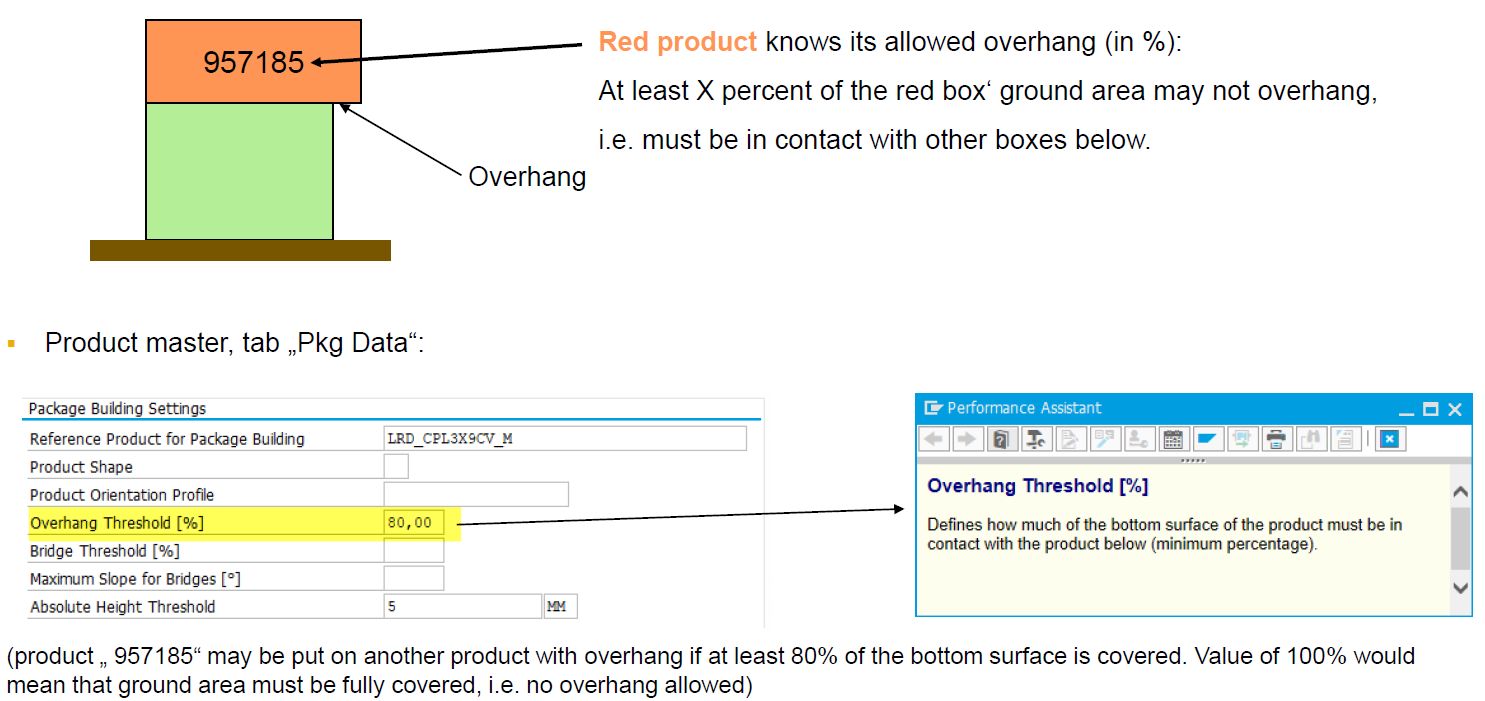

What is overhang stacking?

When creating mixed pallets situations can occur where a for example a lighter product that must be on top of another product, but has a bigger size. This leads to an overhang like shown below. If this is not supported (or correctly defined in the product settings), the PBO will have to use more pallets (of course depending on the product quantities - as long as it can it would place them on the floor next to each other; but as soon as the floor is filled in the example with the green product the setting applies).

Default behavior is that no overhang is allowed. Only when either in the PB profile or for a specific product settings in the threshold are made, this options exists. Note that when a customer has such a scenario it is required to test this very carefully. It is not so easy to setup stable test cases for this. Internally this is mainly done with pretty artificial products and package materials (like in the picture above, where only a single item fits per layer; PBO either finds a solution using a single pallet or not).

Bridge Stacking

Carefully checking the screenshots above one will recognize the additional settings for bridge stacking. This is a master data preparation for the standard as the PBO currently does not support this. It can also be used in custom projects.

Summary

Major piece to get physical. When starting to tackle this, I see the urgent need to start simple to understand the behavior. This is nothing that comes out of the box, is easy to test and understand! Pick simple scenarios, involve business and warehouse people early and increase complexity step by step. Main effect of no having this right is an increased number of required pallets and consequently resources (trucks, trailers, containers). So whenever the situation occurs when warehouse comes back saying more stuff could fit onto a mixed pallet, this is something to check.

Load Plan with detailed packages including stacking constraints

When designing a solution for this, we had in mind to support easy-to-define, but yet powerful constraints. This means:

- Enable default behavior definitions

- Support reference material hierarchy (define each setting on highest possible reference product)

As a consequence, the definitions are spread over multiple spots.

Package Building Profile

The package building profile has been enhanced with 2 new settings. The 'Stacking Sequence' allows to switch the priority between density and weight. The 'Stable Overhang Threshold [%]' enables to define the tolerance when an item can only be stacked when a certain overhang is required.

Enhanced Package Building Profile

Product Definitions

In the product master the packaging data has been enhanced with Package Building Settings. There new settings for overhang, bridge, and non-flat stacking can be found.

TM 9.6 Product master

In the S4 version, the packaging definitions can be found under 'WM Packaging':

S4 Material master

Product Relationship Profile

The final spot for definitions is the new Product Relationship Profile offering stacking settings. Here it is possible to define which product (group) can be on top of another. Note that settings here should only be made in case they are not covered by the Stacking Sequence in the package building profile.

To make it a bit more transparent how the definitions are used by the PBO, I would like to explain the use cases.

What is non-flat stacking?

Depending on the product dimensions, it is possible that a mixed layer forms a non-flat area on top. If no tolerance would be allowed when trying to put something on top, only smaller items could fit.

Overview Non-Flat Stacking

Default behavior is that no non-flat stacking is allowed.

What is overhang stacking?

When creating mixed pallets situations can occur where a for example a lighter product that must be on top of another product, but has a bigger size. This leads to an overhang like shown below. If this is not supported (or correctly defined in the product settings), the PBO will have to use more pallets (of course depending on the product quantities - as long as it can it would place them on the floor next to each other; but as soon as the floor is filled in the example with the green product the setting applies).

Overview Overhang Stacking

Default behavior is that no overhang is allowed. Only when either in the PB profile or for a specific product settings in the threshold are made, this options exists. Note that when a customer has such a scenario it is required to test this very carefully. It is not so easy to setup stable test cases for this. Internally this is mainly done with pretty artificial products and package materials (like in the picture above, where only a single item fits per layer; PBO either finds a solution using a single pallet or not).

Bridge Stacking

Carefully checking the screenshots above one will recognize the additional settings for bridge stacking. This is a master data preparation for the standard as the PBO currently does not support this. It can also be used in custom projects.

Summary

Major piece to get physical. When starting to tackle this, I see the urgent need to start simple to understand the behavior. This is nothing that comes out of the box, is easy to test and understand! Pick simple scenarios, involve business and warehouse people early and increase complexity step by step. Main effect of no having this right is an increased number of required pallets and consequently resources (trucks, trailers, containers). So whenever the situation occurs when warehouse comes back saying more stuff could fit onto a mixed pallet, this is something to check.

- SAP Managed Tags:

- SAP Transportation Management

Labels:

7 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

23 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

37 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

62 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

16

Related Content

- Zamora Company Is Helping Create a Better World by Reducing Packaging with SAP Responsible Design and Production in Supply Chain Management Blogs by SAP

- How To Make PPF Action Configurations Technically for TM Module in Supply Chain Management Blogs by Members

- About Default Credit Limit for new Business Partner in Supply Chain Management Blogs by Members

- SAP IBP (Integrated Business Planning for Supply Chain) – What’s New? (2023) in Supply Chain Management Blogs by Members

- Integrate SAP IBP - Key Figure Delta Δ Data with External Systems in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 10 | |

| 8 | |

| 8 | |

| 5 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 2 |