- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- Monday Knowledge Snippet (MKS) – 87 Detailed Packa...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member18

Active Contributor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

04-08-2019

9:21 AM

With today's MKS I will finally introduce the key improvement of the SCE Package Builder - the Package Building Optimizer. Having kicked-off the topic of detailed package building with MKS79, already spent 7 blogs on parts of the scope and not even touched the core of the feature shows the magnitude of the developments that went into SAP Transportation Management 9.6 (and of course the S4 version).

I already explained a bit of it in MKS79, but here is what comes out of the new Package Builder:

Each to be packaged item has a exact position determined by the PB Optimizer considering constraints like orientation (MKS80), stacking rules, and much more.

With the previous version of the SCE PB, the result looked like this:

The way the PB creates packages that can be built in the warehouse and loaded into a resource follows this sequence (of course respecting package hierarchy aspects - to be cartonized products come first, then the palletization happens):

For step 3 the PB so far applied sequentially two approaches to create mixed pallets:

While for the layer based approach theoretically the PB could have determined physical positions, the volume based approach did not take into account anything in addition to the volume and weight.

It was clear that to become competitive in this area, a huge step forward was required. What looks simple on the pictures above includes many additional definitions and much optimization. It was also clear that we would follow our standard to not tackle this with an ABAP component, but a C++ optimizer (like for the routing and load planning in SAP TM). What's new here is the fact that the SCE PB can also be used in other SAP applications, that might not have had used C++ optimizer engines before. Check the installation guides and the available documentation for this. If there is interest I can also spend an MKS on the basics of this setup.

How can detailed package building be activated?

This can be done in the enhanced Package Building Profile.

As default, the Mixed Package Building uses the volume based approach (to be compatible during upgrade). When selecting 'Detailed Mixed Package Building', the section below also becomes relevant. Here it is possible to:

The new Profiles (Profile for Package Builder Optimizer and Rule Profile for PB Optimizer) can be found in the customizing next to the PB Profile:

Note that if those activities are NOT available, the required business function is not activated. Remember, all of the described new features are in standard only available in SAP TM 9.6, but technically there starting with TM 9.4 as the SCM Basis is the very same. Officially the usage of those features is NOT supported.

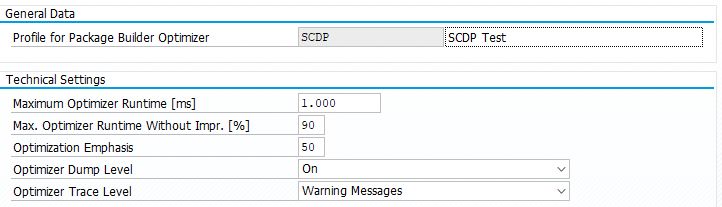

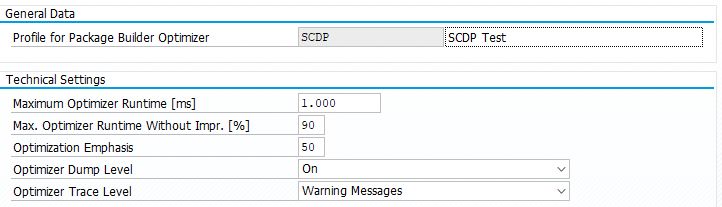

Technical settings in Profile for Package Builder Optimizer

As the integration between the application and the optimizer server is critical, this profile can be used to steer the behavior. Carefully read the documentation and field helps here as the settings can have a massive effect on runtime and result quality!

Functional Settings in Rule Profile for PB Optimizer

The functional behavior is steered by rules to be defined in the Rule Profile.

Those rules are optional. If not defined, the PBO will apply internal default settings. As soon as a single rule is defined, no defaults are applied. Also important here: Carefully read the documentation and field helps! So far the number of supported rules is still limited and very special.

Summary

With the new function available, SAP logistics applications become interesting for customers having the requirement to plan based on realistic packages and pallets. Transportation planning can happen now on pallets that can really be built like this in the warehouse as both applications can use the very same definitions and optimizer. The real physical positions could be used not only for manual instructions, but also for automated mixed pallet building.

I already explained a bit of it in MKS79, but here is what comes out of the new Package Builder:

Each to be packaged item has a exact position determined by the PB Optimizer considering constraints like orientation (MKS80), stacking rules, and much more.

With the previous version of the SCE PB, the result looked like this:

The way the PB creates packages that can be built in the warehouse and loaded into a resource follows this sequence (of course respecting package hierarchy aspects - to be cartonized products come first, then the palletization happens):

- Apply full package quantity for each product (100 pieces of same product make a full pallet)

- Apply full package quantity for homogeneous products (100 pieces of similar products make a full pallet)

- Create mixed packages / pallets for remaining quantities

For step 3 the PB so far applied sequentially two approaches to create mixed pallets:

- Layer based: For each product create homogeneous layers (10 pieces form a stable layer) first. Then try to consolidate products together into homogeneous layers (same height, target fill rate reached). Combine those layers together until the limits are reached.

- Volume based: For items that could not be packaged successfully using layers, the PB applied a volume fill up logic considering the target fill rate of the package material. First it tried to fill up layer based packages that did not reach their limits yet. Then it started new packages until all items were packaged.

While for the layer based approach theoretically the PB could have determined physical positions, the volume based approach did not take into account anything in addition to the volume and weight.

It was clear that to become competitive in this area, a huge step forward was required. What looks simple on the pictures above includes many additional definitions and much optimization. It was also clear that we would follow our standard to not tackle this with an ABAP component, but a C++ optimizer (like for the routing and load planning in SAP TM). What's new here is the fact that the SCE PB can also be used in other SAP applications, that might not have had used C++ optimizer engines before. Check the installation guides and the available documentation for this. If there is interest I can also spend an MKS on the basics of this setup.

How can detailed package building be activated?

This can be done in the enhanced Package Building Profile.

As default, the Mixed Package Building uses the volume based approach (to be compatible during upgrade). When selecting 'Detailed Mixed Package Building', the section below also becomes relevant. Here it is possible to:

- set the default product orientation profile

- decide if mixed pallets shall be built using layers or towers

- how products shall be stacked

- define the technical behavior of the PB Optimizer

- define the functional behavior of the PB Optimizer using Rules

The new Profiles (Profile for Package Builder Optimizer and Rule Profile for PB Optimizer) can be found in the customizing next to the PB Profile:

Note that if those activities are NOT available, the required business function is not activated. Remember, all of the described new features are in standard only available in SAP TM 9.6, but technically there starting with TM 9.4 as the SCM Basis is the very same. Officially the usage of those features is NOT supported.

Technical settings in Profile for Package Builder Optimizer

As the integration between the application and the optimizer server is critical, this profile can be used to steer the behavior. Carefully read the documentation and field helps here as the settings can have a massive effect on runtime and result quality!

Profile for Package Builder Optimizer

Functional Settings in Rule Profile for PB Optimizer

The functional behavior is steered by rules to be defined in the Rule Profile.

Rule Profile

Those rules are optional. If not defined, the PBO will apply internal default settings. As soon as a single rule is defined, no defaults are applied. Also important here: Carefully read the documentation and field helps! So far the number of supported rules is still limited and very special.

Summary

With the new function available, SAP logistics applications become interesting for customers having the requirement to plan based on realistic packages and pallets. Transportation planning can happen now on pallets that can really be built like this in the warehouse as both applications can use the very same definitions and optimizer. The real physical positions could be used not only for manual instructions, but also for automated mixed pallet building.

- SAP Managed Tags:

- SAP Transportation Management

Labels:

3 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

22 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

3 -

Expert Insights

12 -

Expert Insights

35 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

59 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

14

Related Content

- SAP S/4HANA TM Load Optimization – Tricks and Trips for different use-cases – Prioritized truckloads in Supply Chain Management Blogs by SAP

- SAP S/4HANA TM Load Optimization – Tricks and Trips for different use-cases – Dead-stack Loading in Supply Chain Management Blogs by SAP

- S/4 TM Load Optimization - Tricks and Trips for different use-cases - Minimize Product Spread in Supply Chain Management Blogs by SAP

- The 2023 SAP Logistics Private Cloud Advent Calendar Week 1: Release Highlights Rewind in Supply Chain Management Blogs by SAP

- From Chaos to Clarity: Master Data Management (MDM) role in Digital Transformation success in Supply Chain Management Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 9 | |

| 7 | |

| 4 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 |