- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- DDMRP: Buffer Positioning in SAP S/4HANA

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

When we talk about Demand Driven MRP, one of the key aspects is to position the DDMRP buffer correctly: if we buffer too many materials, we will end um with excess inventory, while not buffering enough materials or buffering the wrong materials may lead to material shortages and longer lead times.

To position a buffer for a material in SAP S/4HANA basically means to choose a DDMRP MRP type for a material, so that MRP uses the DDMRP logic and the buffer calculated to plan a material.

The first S/4HANA release to support DDMRP was 1709, and it was launched with the basic tools for DDMRP planning, such as the product classification and buffer calculation. In release 1709 buffer positioning had to be done through the Fiori App Mass Maintenance of Products (DD), which was effective, allowing a DDMRP MRP type to be set for several materials at the same time, but it was not exactly intuitive, as we could not see the whole picture when choosing to buffer a material.

In summary, a visual and intuitive tool to support the user on choosing which materials within the product structure should be actually buffered was missing in S/4HANA 1709.

As of SAP S/4HANA 1809, we have a Fiori App called Buffer Posiitioning, which supports the user on choosing which specific materials within the product structure should be buffered.

In this blog we will explore this new Fiori App in detail and understand how can it help us to choose during the DDMRP buffer positioning.

Launching the Buffer Positioning app

We we open the buffer positioning app, we can apply filters and select one or several materials work with. By marking one or several materials from the list, we immediately see the options to calculate the Decoupled Lead Time, Buffer (set a DDMRP MRP type) or Unbuffer, as we can see in Figure 1.

Figure 1: Buffer Positioning initial screen

Buffer Analysis

Besides these options immediately available in the initial screen, we also have the option to click one a specific line and branch into a detailed view for the selected material, called Buffer Analysis, as shown in Figure 2.

In the Buffer Analysis screen, we see the sections Upstream an Downstream, with details about child and parent materials. By default, in the Upstream section, we see the Longest Path within the product structure. Please observe that this is not the longest path within the whole product structure, but the longest path until reaching the next buffered material (with a DDMRP MRP Type).

Figure 2: Buffer Analysis

In the Downstream section we will see by default the Immediate Parent material. In both cases, however, we have options to switch between different views. In the Upstream view we can see the whole bill of material, while in the Downstream view we can see the next buffers or the finished products above the selected material. Figure 3 shows the BOM in the Upstream view.

Figure 3: BOM in the upstream view.

Network Graph View

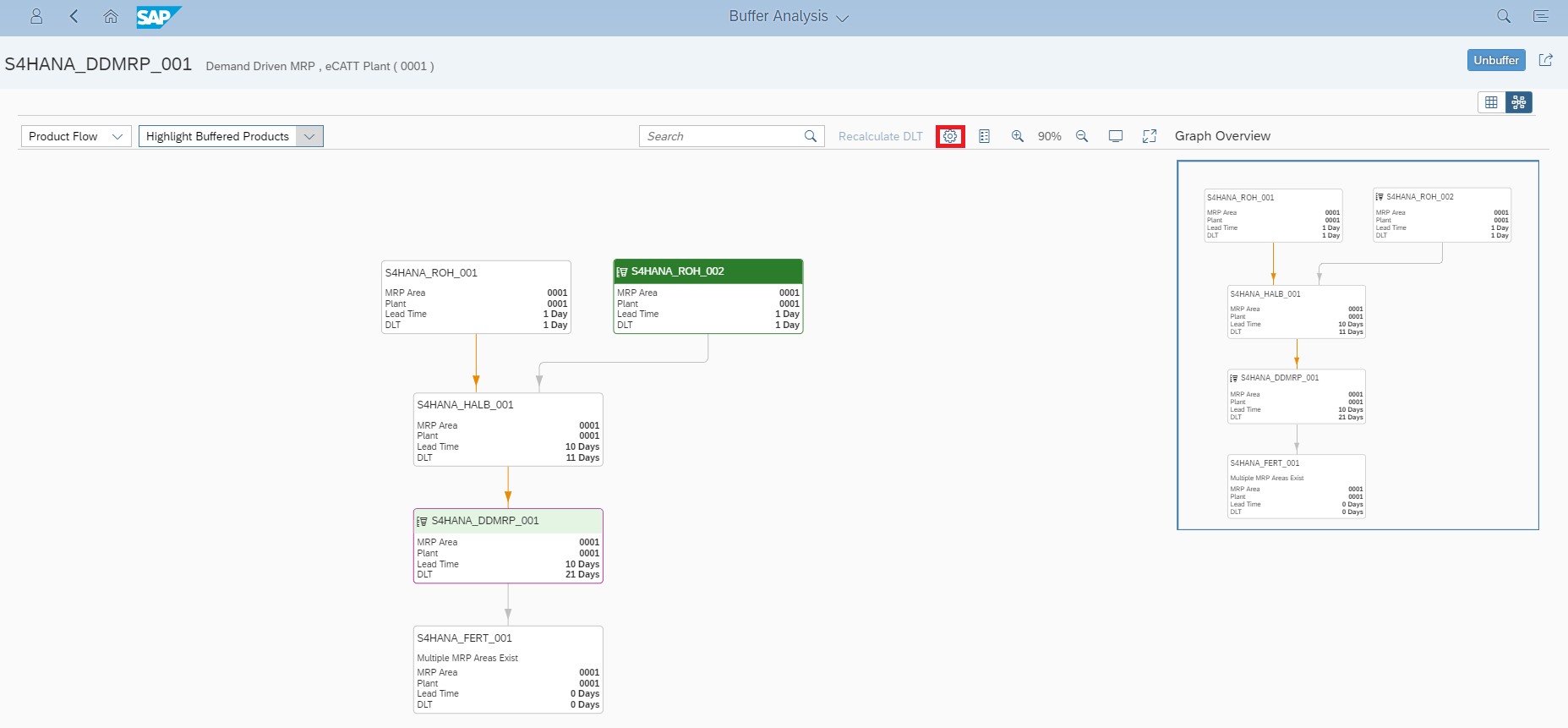

Things get really interesting when we change to the Network Graph analysis, as shows in Figure 4. Here, we have a graphical view of the whole product structure and we can easily identify decoupling points to position the DDMRP buffer.

Figure 4: Network Graph

There are many options to improve visualization, such as Highlighting specific materials within the product structure. In Figure 5 we can see all the buffered materials within the complete product flow.

For products with a larger bill of material, we can also switch to a Top-Down visualization, by clicking the settings button.

Figure 6: Top-Down view

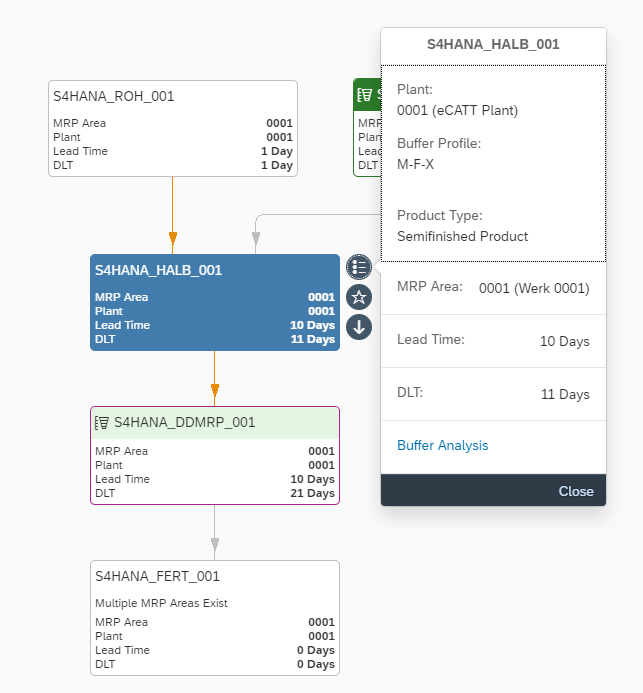

In the Network Graph we can also have details about any specific material and even switch to the Buffer Analysis of a different material.

With this kind of graphical display of the product structure we can identify what is the best point to add a buffer within the product structure, reducing the total product lead time. It also allows us to avoid unnecessary buffers, which would eventually increase inventory and the associated costs. In summary, it a great tool for buffer positioning, with a great and intuitive user interface.

- SAP Managed Tags:

- SAP S/4HANA,

- MAN Production Planning (PP),

- MM (Materials Management),

- SAP S/4HANA Public Cloud

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

22 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

157 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

217 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

- SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release – Part 2 in Enterprise Resource Planning Blogs by SAP

- Foundational Elements for Harnessing the Power of Business AI in Your SAP S/4HANA Cloud Public Ed. in Enterprise Resource Planning Blogs by SAP

- Sustainability with SAP S/4HANA Cloud Public Edition 2402 in Enterprise Resource Planning Blogs by SAP

- Manufacturing in SAP S/4HANA Cloud Public Edition 2402 in Enterprise Resource Planning Blogs by SAP

- Environment, Health and Safety in SAP S/4HANA Cloud, Private Edition 2023 in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 13 | |

| 11 | |

| 10 | |

| 8 | |

| 7 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 3 |