- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Map cure time / quarantine time of Mfg. Products w...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member59

Member

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

11-22-2018

5:31 AM

Requirements-

Quarantine/Cure time - Often in industries like food, paper, steel, building products, chemicals and many more , you need to hold products in quarantine to allow it to get it cured before it can be sold to customers just because of the physical and chemical nature of these products. As these materials are being cooled down and being cured, you cannot yet ship to customer. SAP does not offer a standard solution for this scenario in ECC. Below blog explains how quality inspection can be used to map this scenario in standard SAP.

Solution Steps-

Below enhancements are needed to make above process work-

2.Enable editing of cure time for specific production run for the materials in individual inspection lots in QA02/QA03 transactions-

Inspection start date and end date are available on inspection lot change screen in transaction QA02 as standard SAP.

Inspection start time and end time can be enabled on QA02 screen with below enhancement.

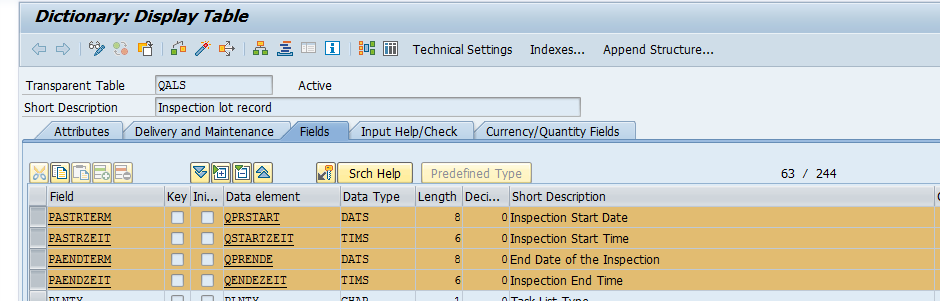

Insp. Start date: - QALS- PASTRTERM Insp. Start time: - QALS-PASTRZEIT Insp. End date: - QALS- PAENDTERM Insp. End time: - QALS-PAENDZEIT

Enhancement QPL10004 can only update fields from customer include structure CI_QALS and cannot directly display or edit QALS original table fields from this user exit.

Below solution approach would be used to meet our requirement of this enhancement

Implicit enhancement-Program- SAPLQP1 /LQPL1F3X

Update QALS table time fields with time fields from customer include structure I_QALS_CUST.Form-GET_CI_QALS

As a result of this enhancement cure time start and end dates along with times are enabled in QA02 as shown below-

3) Enhancement – Auto Usage Decision batch job set up with QA10/QA19We can automate process of releasing quality inspection stock under quarantine to unrestricted inventory upon completing the cure time. QA10/QA19 transactions can be used to perform automatic usage decisions with usage decision codes that are capable of moving inventory from QI to unrestricted stock. These usage decision codes will need to be configured in QS41 and QS51 transactions separately and to be stored in variant for QA10/QA19

QA10/QA19 transactions can also be set up as background job. We will need to enhance and add custom criterion to select only those inspection lots for Usage Decision for which Inspection end date and end time both have been reached by comparing it with current system date and time.

Implicit enhancement in program- RQEVAI30

Business benefits-

Quarantine/Cure time - Often in industries like food, paper, steel, building products, chemicals and many more , you need to hold products in quarantine to allow it to get it cured before it can be sold to customers just because of the physical and chemical nature of these products. As these materials are being cooled down and being cured, you cannot yet ship to customer. SAP does not offer a standard solution for this scenario in ECC. Below blog explains how quality inspection can be used to map this scenario in standard SAP.

Solution Steps-

- This requirement can be met by activating goods receipt inspection for cure time relevanmaterials. You will need to activate 04 inspection type in material master for these products.

- Key settings in material master QM view is ’Average inspection duration’ which can be mapped as cure time of material. As a standard SAP this field stores duration in number of days. Enhancement can be activated to map this average inspection duration in hours instead of days as explained later. You can maintain cure time up to 999 hours max which should be enough for most industry standard products.

- If you need final inspection with quality attributes to be done for these materials then activate and set up additional master data like MIC's, Sampling procedure and inspection plans otherwise set up material master QM view in such a way that inspection lots created during goods receipt will be not relevant for inspection with task list and can be closed with automated usage decisions.

- Once you have activated cure times in hours with enhancement then you can also track exact start and end of cure times stamps by enabling inspection start time and end time fields from QALS table on inspection lot screen of QA02/QA03 which can be done with another enhancement as explained later. This will also allow you to change cure time for specific batch of production inside inspection lot on as needed basis.

- At the time of production goods receipts, an inspection lot will be created with inspection lot start date and time as time of goods receipt and scheduled inspection lot end date and time based on material master cure time, material will be placed in inventory as stock under quality Inspection stock type.

- A background program will be scheduled to run periodically throughout the day to release stock quantity held in quality Inspection stock type to unrestricted stock type based on Inspection Lot processing end date and end time. Only the quantities held under the inspection lots meeting the end date/time selection parameters will be released by comparing it with current date and time.

- If stock needs to be made available prior to the quarantine/cure expiration time, or if the quarantine/cure time needs to be extended for the specific stock quantity held under the inspection lot, an operator with the proper authority can manually release the stock quantity to available stock or extend the quarantine/cure day for the specific inspection lot quantity.

- Integration with planning systems- With enhancement, you can CIF these cure times from material master to planning systems like APO and add this duration to lead time offset of materials planning in APO which will make sure planned duration of production/ process orders have cure time built into the order durations for planning purposes.

- Integration with ATP- Activate QI stock in ATP scope of planning in ECC or GATP in APO. This will ensure materials receipts that are under curing is still relevant for shipping and can be committed at the end of its cure time for sales to customers.

- If you operate and have Mfg. plants across geographical regions with different time zones, then all dates and time for inspection lot processing will be in time zone of SAP server to keep the design simple and consistent.

Below enhancements are needed to make above process work-

- Mapping cure time in hours instead of days in inspection lot creation process-When Inspection lot end date is calculated by standard SAP, it would consider average inspection duration from material master as duration in days and calculate end date accordingly. This enhancement will change this standard behavior to consider the average inspection duration from material master as hours instead of days. When a goods receipt is posted, SAP will create an Inspection lot. The inspection start date is the system date at the time of goods receipt and set by the system automatically. SAP Inspection lot header table QALS have Inspection start time and end time fields but these are not used currently in standard SAP functionality. They are set to 00:00:00 when inspection lot is created in standard SAP. These can be utilized to store exact start and end times of quarantine times for material.

Enhancement QAPL1001 allows changing inspection lot details – This will get called from goods receipt transaction of process/production order and will allow us to change the date / time on inspection lot.Inspection lot start date: - SAP current system date (GR date)Inspection lot start time: - SAP current system time.Inspection lot end date: - system should have calculated it with Average inspection duration from material master, overwrite it with new end date calculated based on curing time in hours.

Enhancement QAPL1001 allows changing inspection lot details – This will get called from goods receipt transaction of process/production order and will allow us to change the date / time on inspection lot.Inspection lot start date: - SAP current system date (GR date)Inspection lot start time: - SAP current system time.Inspection lot end date: - system should have calculated it with Average inspection duration from material master, overwrite it with new end date calculated based on curing time in hours.

Inspection lot end time: - Calculate end time along with end date by adding curing time in hours to start date and start time.

QPL10001 QM: Inspection lot creation - editing work area on creation

2.Enable editing of cure time for specific production run for the materials in individual inspection lots in QA02/QA03 transactions-

Inspection start date and end date are available on inspection lot change screen in transaction QA02 as standard SAP.

Inspection start time and end time can be enabled on QA02 screen with below enhancement.

Insp. Start date: - QALS- PASTRTERM Insp. Start time: - QALS-PASTRZEIT Insp. End date: - QALS- PAENDTERM Insp. End time: - QALS-PAENDZEIT

Enhancement QPL10004 can only update fields from customer include structure CI_QALS and cannot directly display or edit QALS original table fields from this user exit.

Below solution approach would be used to meet our requirement of this enhancement

- Enhancement QPL10004 will be enabled which will add a sub screen to inspection lot change display transaction. Customer include structure CI_QALS will be activated Z fields and start time and end time will be added to them.

- Enhancement QPL100001 will be used to populate 2 custom fields for start time and end times of cure time. QALS-CI_QALS-ZZPASTRZEIT QALS- CI_QALS-ZZPASTRZEIT

- QA02/QA03 Will show time on new sub screen should be added based on ZZ fields from QALS with enhancement QPL10004.

- Users will be able to change these times as required and below Implicit enhancement will be used to update back changed end time on original QALS time fields QALS-PASTRZEIT & QALS-PAENDZEIT

Implicit enhancement-Program- SAPLQP1 /LQPL1F3X

Update QALS table time fields with time fields from customer include structure I_QALS_CUST.Form-GET_CI_QALS

As a result of this enhancement cure time start and end dates along with times are enabled in QA02 as shown below-

3) Enhancement – Auto Usage Decision batch job set up with QA10/QA19We can automate process of releasing quality inspection stock under quarantine to unrestricted inventory upon completing the cure time. QA10/QA19 transactions can be used to perform automatic usage decisions with usage decision codes that are capable of moving inventory from QI to unrestricted stock. These usage decision codes will need to be configured in QS41 and QS51 transactions separately and to be stored in variant for QA10/QA19

QA10/QA19 transactions can also be set up as background job. We will need to enhance and add custom criterion to select only those inspection lots for Usage Decision for which Inspection end date and end time both have been reached by comparing it with current system date and time.

Implicit enhancement in program- RQEVAI30

Business benefits-

- This process will allow you to avoid shipping materials that are not ready yet to customers and avoid penalties and unnecessary customer returns.

- You can still commit these materials under quarantine in ATP based on cure times of material for orders and demand in future.

- This can also be integrated with final quality inspection with quality attributes.

- SAP Managed Tags:

- Automotive,

- Chemicals,

- PLM Quality Management (QM)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

learning content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- How to add custom field to production order output in Enterprise Resource Planning Q&A

- Posting Journal Entries with Tax Using SOAP Posting APIs in Enterprise Resource Planning Blogs by SAP

- Differences between SAP MRS , FSM and RSH in Enterprise Resource Planning Q&A

- Revision level on products- different per plant ? in Enterprise Resource Planning Q&A

- SAP S/4HANA Cloud, public edition, ABAP Environment Case 8: Material Shelf Life Management in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |