- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- What´s new in IBP Response and Supply 1808 - Order...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Employee

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

08-12-2018

5:11 AM

Hi everyone

With Release 1808 in IBP for Response and Supply a lot of new features and functions for the order-based planning process were offered.

Highlights in 1808:

- Component lead-time offset – Enables the ability to plan component requirements so they are defined by activity start date, giving a more accurate representation of when they’re needed in the order-based model.

- Version-specific master data – Allows for different simulation capabilities, with the ability to change master data field values in non-base versions via Excel Master Data Maintenance in the order-based model.

Component lead-time offset:

When planned orders have long lead times, companies have the need to schedule component requirements different from the planned order start date. Otherwise it can result in components being procured much earlier than they are actually needed in the production process.

To avoid this situation planners want to be able to maintain component lead-time offset for the components in relation to the start date for production of the superior material.

With IBP1808 you are able to model component lead-time offset. Activities are the means to model component lead-time offset for the IBP planning runs.

Activities are considered in all IBP OBP planning runs that create planned orders. For the job template “Constrained Forecast Run using Optimizer” there is a restriction to one activity (activity needs a duration > 0).

Note: IBP OBP does not support the lead-time offset defined for components in the Change Material BOM transaction of SAP ERP or SAP S/4 HANA.

System example:

Activities and component assignment:

Planning result:

For more information, see documentation of Component Lead-Time Offset.

Or watch the video (4:51min): Component Offset/multi Activities in Order-based Planning SAP IBP for Response and Supply 1808

Version specific master data

Set up a version with version-specific master data for order-based planning:

A version in a planning area can be defined to have version-specific master data. With this what-if scenarios with alternative master data can be executed and planned.

If the planning area is used in order-based planning, such a version can be defined in the settings for order-based planning to have a planning version with

- either version-specific master data (what-if)

- or use the operative master data (no versioning for external MDTs)

Copy master data and generate planning objects:

If the planning version is defined to have version-specific master data, the master data can initially be copied from a source planning version using the application job ‘Order-Based Planning: Copy Version Data’. This job is able to copy order and master data if required.

Regeneration of planning objects is required for versions with version-specific master data. This enables visibility of external key figures for the planning area version in Excel.

Adjust master data from excel:

In 1808 it is possible to edit external master data types via EXCEL when the version of the planning area is defined to have version-specific master data in order-based planning

It is possible to change a certain list of attributes of the different master data types enabled for change. Create and delete of master data type is yet not in scope.

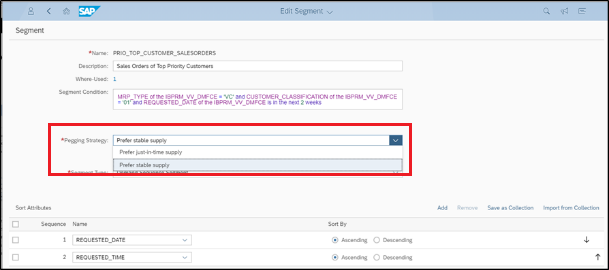

Pegging Strategy “Prefer stable supply”

“Prefer just-in-time supply”

- Use fixed supply like stock, purchase orders or other fixed supply from execution that could fulfill the demand in-time if available. If there are multiple fixed supply elements available to fulfill the demand in time use the latest one.

- If there is no fixed supply available create new planned supply like planned orders and purchase requisitions as late as possible.

- If a lower prioritized demand can only be fulfilled by fixed supply, that is already consumed by higher prioritized demands with a planned date further in the future, then free up the fixed supply if the higher prioritized can be fulfilled by new planned supply.

“Prefer stable supply”

- Use fixed supply like stock, purchase orders or other fixed supply from execution that could fulfill the demand in-time if available. If there are multiple fixed supply elements available to fulfill the demand in time use the earliest one.

- If there is no fixed supply available create new planned supply like planned orders and purchase requisitions as late as possible.

- Lower prioritized demands are not allowed to use fixed supply, that is already consumed by higher prioritized demands even if the higher prioritized can be fulfilled by new planned supply.

Pegging strategy “Prefer just-in-time supply” provides goods results with relation to service levels (fulfillment of primary demands) and projected stock levels

Pegging strategy “Prefer stable early supply” guaranties, that stable supply is allocated to high prioritized orders, even though missing components lead to a late confirmation. This avoids unrealistic confirmations for lower prioritized orders and provides the planner the possibility to improve the supply situation for the missing components.

Define pegging strategy in Rules for Demand Prioritization:

Define pegging strategy for the pre-allocation segment on rules header for

- Deliveries

- Dependent demands of fixed elements

- Supply elements within the freeze horizon (considered as fixed)

Define pegging strategy for all demands covered by the segment condition within the segment

Demands for Safety Stock and Adjusted Quantities will always be planned using pegging strategy „Prefer just-in-time supply“.

Typically if a segment uses pegging strategy „Prefer just-in-time supply“, all following segments should use pegging strategy „Prefer just-in-time supply“, as well.

Analyze pegging results in Analyze Supply Usage:

Analyze Supply Usage provides information about the pegging strategy that was used by last planning for each demand element.

Together with the information about stable (fixed) supply it is possible to filter for demands that are planned with pegging strategy “Prefer stable supply” consuming not fixed supply and vice versa

Find additional information about the Pegging Strategies in Comparison

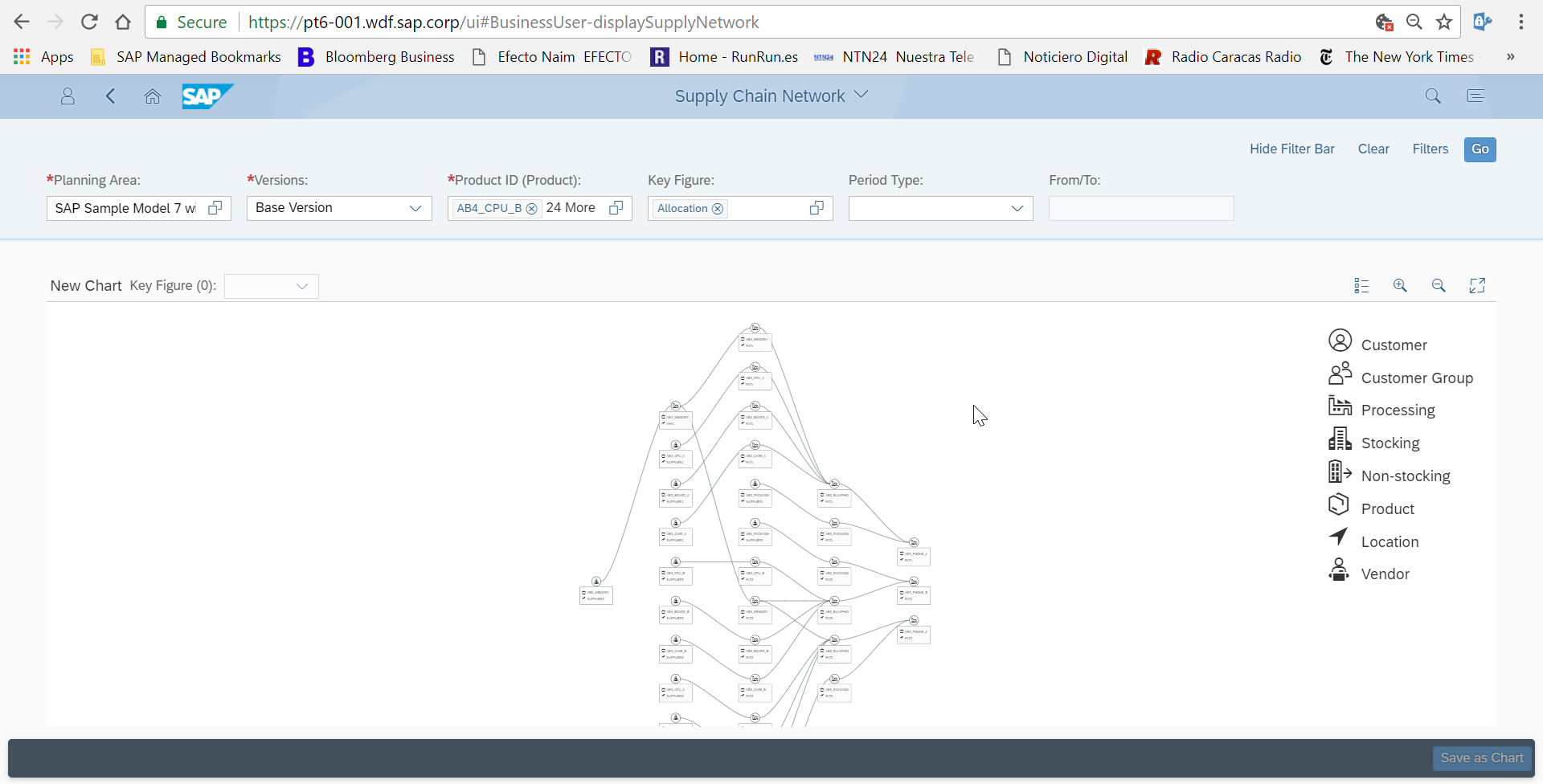

Enhancements to Fiori Supply Chain Network Application

Render networks for IBP for response (SAP7) and IBP for response & supply (SAP74) sample models.

Planning in multiple planning area

From 1808 on it is possible to define multiple planning areas for use in order-based planning.

For further details please watch this video (8:15min):

Multiple Planning Areas in Order-based Planning SAP IBP for Response and Supply 1808

Deletion of order-based master data in IBP

- Up to IBP 1805 the deletion of order-based master data was only possible with the usage of the option “Erase Prev. Integrated Data” during the inbound integration

- With IBP 1808 during the inbound integration of the order-based data, the master data which can be deleted in IBP are marked for deletion

- Master data can be deleted only, when no dependent master- and transactional data exists within an order-based planning area/version exists

- The new application job “Order-based Planning: Delete Master Data” is introduced. The job collects all master data which are marked per planning area/version and removes them from the system. It is recommended to execute this application job periodically. The application job can also be executed in simulation mode

Find additional information for all topics in the help documentation

Try it out!

- SAP Managed Tags:

- SAP Integrated Business Planning for Supply Chain,

- SAP Supply Chain Management

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

23 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

38 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

65 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

- 5 Reasons why Planners Should Consider the RISE with SAP Advanced Supply Chain Planning Package in Supply Chain Management Blogs by SAP

- Integrating SAP Datasphere with SAP Integrated Business Planning, using SAP CI - Part 2 in Supply Chain Management Blogs by SAP

- Integrating SAP Datasphere with SAP Integrated Business Planning, using SAP CI - Part 1 in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 9 | |

| 8 | |

| 6 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 |