- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Fixed Bin concept in SAP WM vs EWM

Supply Chain Management Blogs by Members

Learn about SAP SCM software from firsthand experiences of community members. Share your own post and join the conversation about supply chain management.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

former_member24

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

06-27-2018

5:38 AM

This document is to give the brief overview on the fixed bin concept of SAP Warehouse Management and SAP Extended Warehouse Management.

Most of warehouses prefer to keep the stock in constant storage bins , so that they can have some ease in doing the physical transactions especially for the warehouse users who are working in the warehouses since long time.

In general fixed bin concept or fixed bin put away is nothing but every material is mapped with unique storage bin , so that when put away is happening , system will suggest the respective bin to storage that particular material.

In SAP WM , to achieve the fixed bin we need to follow the below steps

As a first step we need to assign the put away strategy "F- Fixed bin" to the storage type where we are going to store the materials

Configuration path : IMG --> Logistics Execution --> Warehouse Management --> Master data --> Define Storage type

Once we assign the fixed bin strategy to the storage type , then we have make sure that every material is assigned with the storage bins of that particular storage type . This can be done in assigning the storage bin in material master - warehouse management 2 view

T.Code : MM02 / MM01

by having these two settings we can activate the fixed bin strategy in SAP ERP WM.

With proper "Activate storage type search" configuration, and stock placement indicator in material type helps to identify the storage type . Once the storage type identified then Fixed bin put away strategy will play a role to identify the storage bin.

Here in SAP WM ,there is a limitation of assigning only one storage bin to the material master. we can only assign one bin to the material master. If the bin is occupied , then system will suggest reserve storage type based on our configuration . Some times "Near picking bin -K " put away strategy helps in those conditions like if system could not place the stock in fixed bins.

This limitation has overcame in EWM , we can manage multiple storage bins for single material in EWM.

In EWM we need to configure the storage type to deal with fixed bin storage. check boxes "Use Fixed bins" and "Check max no. bins" will influence the fixed bin storage.

In customizing for SCM Extended Warehouse Management, go to Extended Warehouse Management → Master Data → Define Storage Type.

after having this check boxes marked , we need to adopt the storage type data and maintain the maximum number of bins in warehouse product

/SCWM/MAT1

After this we need to assign the fixed storage bins to the product by using following path

From the EWM Index screen, choose Extended Warehouse Management → Master Data → Storage Bin → Assign Fixed Storage Bins to Products

or

/SCWM/FBINASN

enter the product number , warehouse and storage type and No.of storage bins to be maintained for that product . With this transaction , system automatically assigns the storage bins based on the sequence.

or else fixed storage bins can be maintained manually using the below transaction or path

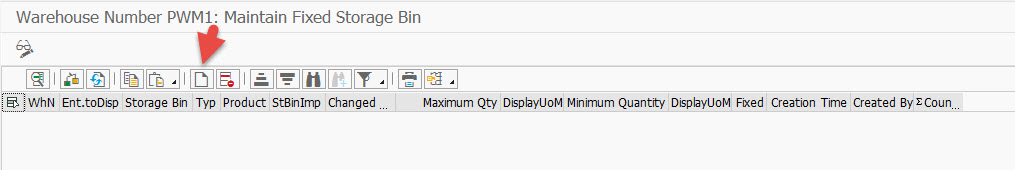

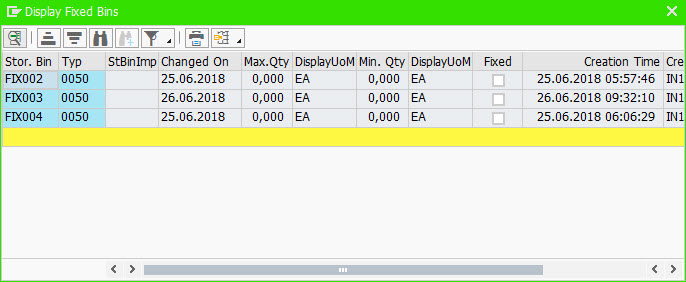

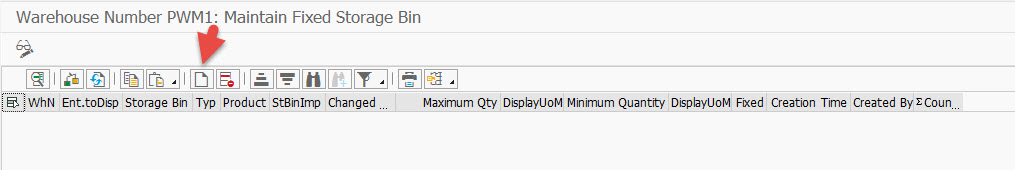

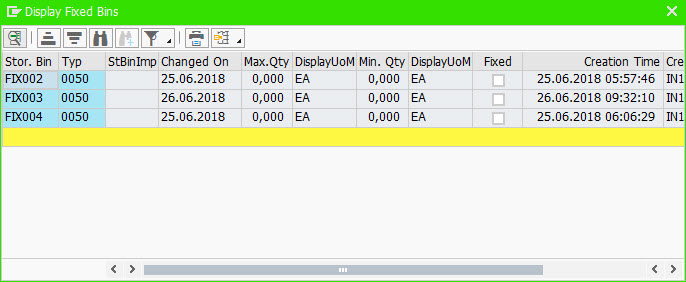

From the EWM Index screen, choose Extended Warehouse Management → Master Data → Storage Bin → Maintain Fixed Storage bin

By clicking on new entry button , we can maintain the storage bin to warehouse product.

Once all this master data settings done , with the put away control indicator , Storage type search sequence configuration will helps to identify the right storage type to put away the goods . Once storage type identified system will suggest fixed bins based on our settings.

fixed bins can be seen from the product master as well

/SCWM/MAT1

Thanks

Santhosh Surata

Most of warehouses prefer to keep the stock in constant storage bins , so that they can have some ease in doing the physical transactions especially for the warehouse users who are working in the warehouses since long time.

In general fixed bin concept or fixed bin put away is nothing but every material is mapped with unique storage bin , so that when put away is happening , system will suggest the respective bin to storage that particular material.

In SAP WM , to achieve the fixed bin we need to follow the below steps

As a first step we need to assign the put away strategy "F- Fixed bin" to the storage type where we are going to store the materials

Configuration path : IMG --> Logistics Execution --> Warehouse Management --> Master data --> Define Storage type

Once we assign the fixed bin strategy to the storage type , then we have make sure that every material is assigned with the storage bins of that particular storage type . This can be done in assigning the storage bin in material master - warehouse management 2 view

T.Code : MM02 / MM01

by having these two settings we can activate the fixed bin strategy in SAP ERP WM.

With proper "Activate storage type search" configuration, and stock placement indicator in material type helps to identify the storage type . Once the storage type identified then Fixed bin put away strategy will play a role to identify the storage bin.

Here in SAP WM ,there is a limitation of assigning only one storage bin to the material master. we can only assign one bin to the material master. If the bin is occupied , then system will suggest reserve storage type based on our configuration . Some times "Near picking bin -K " put away strategy helps in those conditions like if system could not place the stock in fixed bins.

This limitation has overcame in EWM , we can manage multiple storage bins for single material in EWM.

In EWM we need to configure the storage type to deal with fixed bin storage. check boxes "Use Fixed bins" and "Check max no. bins" will influence the fixed bin storage.

In customizing for SCM Extended Warehouse Management, go to Extended Warehouse Management → Master Data → Define Storage Type.

after having this check boxes marked , we need to adopt the storage type data and maintain the maximum number of bins in warehouse product

/SCWM/MAT1

After this we need to assign the fixed storage bins to the product by using following path

From the EWM Index screen, choose Extended Warehouse Management → Master Data → Storage Bin → Assign Fixed Storage Bins to Products

or

/SCWM/FBINASN

enter the product number , warehouse and storage type and No.of storage bins to be maintained for that product . With this transaction , system automatically assigns the storage bins based on the sequence.

or else fixed storage bins can be maintained manually using the below transaction or path

From the EWM Index screen, choose Extended Warehouse Management → Master Data → Storage Bin → Maintain Fixed Storage bin

By clicking on new entry button , we can maintain the storage bin to warehouse product.

Once all this master data settings done , with the put away control indicator , Storage type search sequence configuration will helps to identify the right storage type to put away the goods . Once storage type identified system will suggest fixed bins based on our settings.

fixed bins can be seen from the product master as well

/SCWM/MAT1

Thanks

Santhosh Surata

- SAP Managed Tags:

- SAP Extended Warehouse Management

8 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

Related Content

- RISE with SAP advanced PLM package in Supply Chain Management Blogs by SAP

- 5 Reasons why Planners Should Consider the RISE with SAP Advanced Supply Chain Planning Package in Supply Chain Management Blogs by SAP

- EWM Putaway Storage Section Indicator Defaulting to Incorrect Putaway Bin in Supply Chain Management Q&A

- Advanced Shipping and Receiving – Go-live support insights in bgRFC based EWM-TM integration in Supply Chain Management Blogs by SAP

- HU and Packaging Material Type in EWM S/4 in Supply Chain Management Q&A

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |