- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- From Our Customers’ Perspective: New Paths Forward...

Supply Chain Management Blogs by SAP

Expand your SAP SCM knowledge and stay informed about supply chain management technology and solutions with blog posts by SAP. Follow and stay connected.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Advisor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

03-29-2018

1:56 PM

In a previous blog, I walked through some of the features in SAP Integrated Business Planning. But the question remains: how are customers actually using it? Let’s take a look.

Improving the customer experience

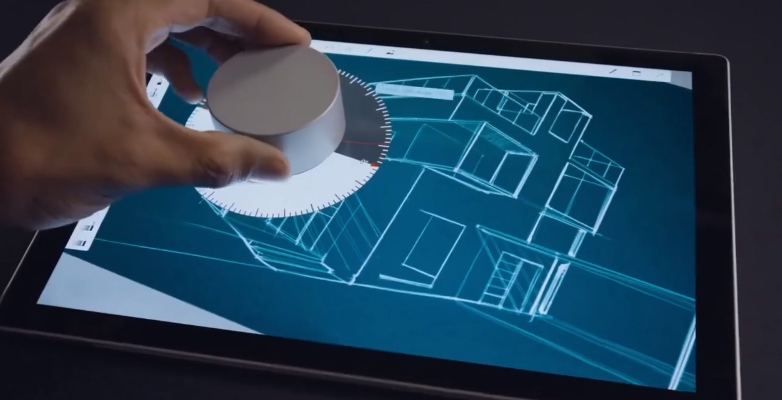

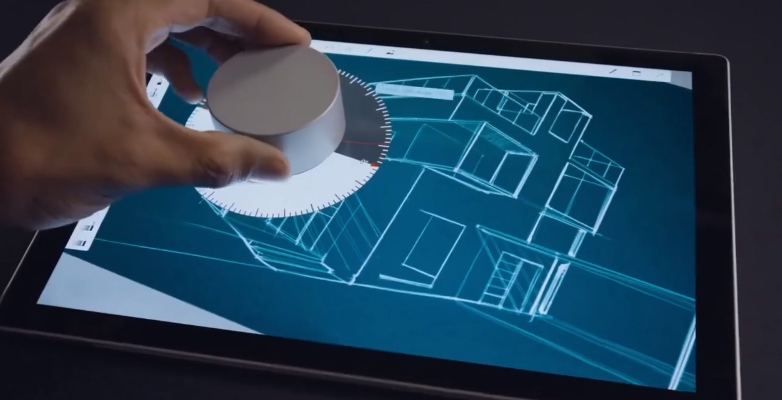

Some customers are using SAP IBP to deliver personalized products that improve experiences and outcomes for their customers. Take the software giant from Redmond, for instance.

When Microsoft launched the Surface – one of the most successful laptop/tablets out there today – the company also launched a new initiative it calls One Digital Supply Chain (One DSC). To deliver variations on the Surface that meet differentiated needs across markets, channels, and customers, Microsoft wanted a demand-driven supply chain platform that could be scalable, flexible, and adaptive to change.

Microsoft is realizing this vision with SAP IBP and SAP Ariba Supply Chain Collaboration, which has helped the company dramatically cut the time required to onboard new partners. Corey Hughes is Principal Program Manager for Supply Chain Business Technologies at Microsoft. According to Hughes, Microsoft can now “activate a very different supply chain in a matter of weeks, rather than months or years.”

This gives Microsoft the agility it needs to consistently deliver what customers want. In the past, “we didn't have a notion of what it means to assemble a product to order,” says Hughes. Now – with an understanding of where products and materials are at any point in time – Microsoft has the visibility and insight it needs to meet even individualized demand. And with a more efficient supply chain geared toward meeting customer needs, Microsoft has been able to see “$300 million of working capital improvement with a five percent increase in our on-time in-full measurement.”

Linking strategic objectives to execution

While improving the customer experience is critical for success in a digital economy, it is, admittedly, a high-level strategic objective. How then do you link such objectives to day-to-day operations and execution for supply chain pros in the trenches?

ArcelorMittal, a global leader in integrated steel production, did it by using SAP IBP to increase planning process transparency across sales, supply, manufacturing, and distribution. A familiar, easy-to-use, Excel-based interface has ensured wide-spread adoption while sophisticated simulation tools have helped to speed decision making. The result has been greater alignment across supply chain players leading to lower inventory levels, better quality of stock, and improved sales forecasts.

Similar results were achieved by Prestige Brands Holdings, a leading producer of personal and household wellness products. Prestige – which needed faster, easier access to business and supply chain data across sales, operations, and marketing teams – has been able to centralize planning data, improve collaboration, and even speed up business warehouse response times. “With SAP Integrated Business Planning,” says Matt Flood, Vice-President and CIO, at Prestige, “our sales VP can do annual sales quota planning in a few hours compared to days. All sales team members can collaborate and achieve consensus sales forecast numbers centrally and provide visibility to the management team instantaneously.”

A leading producer of antibiotics and other pharmaceuticals, DSM Sinochem Pharmaceuticals aimed to repurpose working capital tied up in manual supply chain processes. With SAP IBP deployed in the cloud, the company was able to develop a single version of the truth for planning. This has helped to ease the manual workload for DSM’s supply chain managers while increasing agility when it comes to plan changes. One key measure of success so far: a 20% improvement in forecast accuracy over 3 years.

The list goes on

As a tool for transforming supply chains into agile demand networks for success in a digital economy, SAP IBP is helping companies all over the world blaze new trails. Already, we’ve covered industries in high tech, consumer products, pharmaceuticals, and metal and mining. But the list goes on.

Take, for example, a handful of customers with “international” in their names. Blount International – a manufacturer in the forestry, agriculture, and construction industries – has used SAP IBP for better analysis and forecasting in support of a build-to-stock model that has helped enhance customer fill rates, increase inventory turns, and reduce stock levels. Mondelēz International – one of the world's largest snacks companies – has created a single version of the truth that facilitates a “One Number” plan to align the entire organization. And Lennox International – a leader in HVAC and refrigeration – has increased supply chain transparency and efficiency, with results such as 80% better forecast accuracy and 90% less time needed for data collection.

Yes, when it comes to SAP IBP, the list goes on. The question is: Are you on it?

If not, think about coming to the 2018 SAPPHIRE NOW conference – where you’ll learn more about what SAP IBP can do to help your company compete more effectively in the digital economy. Last, year, we had Colgate, Corning, Hewlett Packard Enterprise, and Monsanto discuss their transformation stories live on stage.

For more statistics and insight on competing in the digital age, check out the new IDC infobrief, sponsored by SAP, Digital Business Planning Is at the Heart of Supply Chain Transformation

Improving the customer experience

Some customers are using SAP IBP to deliver personalized products that improve experiences and outcomes for their customers. Take the software giant from Redmond, for instance.

When Microsoft launched the Surface – one of the most successful laptop/tablets out there today – the company also launched a new initiative it calls One Digital Supply Chain (One DSC). To deliver variations on the Surface that meet differentiated needs across markets, channels, and customers, Microsoft wanted a demand-driven supply chain platform that could be scalable, flexible, and adaptive to change.

Microsoft is realizing this vision with SAP IBP and SAP Ariba Supply Chain Collaboration, which has helped the company dramatically cut the time required to onboard new partners. Corey Hughes is Principal Program Manager for Supply Chain Business Technologies at Microsoft. According to Hughes, Microsoft can now “activate a very different supply chain in a matter of weeks, rather than months or years.”

This gives Microsoft the agility it needs to consistently deliver what customers want. In the past, “we didn't have a notion of what it means to assemble a product to order,” says Hughes. Now – with an understanding of where products and materials are at any point in time – Microsoft has the visibility and insight it needs to meet even individualized demand. And with a more efficient supply chain geared toward meeting customer needs, Microsoft has been able to see “$300 million of working capital improvement with a five percent increase in our on-time in-full measurement.”

Linking strategic objectives to execution

While improving the customer experience is critical for success in a digital economy, it is, admittedly, a high-level strategic objective. How then do you link such objectives to day-to-day operations and execution for supply chain pros in the trenches?

ArcelorMittal, a global leader in integrated steel production, did it by using SAP IBP to increase planning process transparency across sales, supply, manufacturing, and distribution. A familiar, easy-to-use, Excel-based interface has ensured wide-spread adoption while sophisticated simulation tools have helped to speed decision making. The result has been greater alignment across supply chain players leading to lower inventory levels, better quality of stock, and improved sales forecasts.

Similar results were achieved by Prestige Brands Holdings, a leading producer of personal and household wellness products. Prestige – which needed faster, easier access to business and supply chain data across sales, operations, and marketing teams – has been able to centralize planning data, improve collaboration, and even speed up business warehouse response times. “With SAP Integrated Business Planning,” says Matt Flood, Vice-President and CIO, at Prestige, “our sales VP can do annual sales quota planning in a few hours compared to days. All sales team members can collaborate and achieve consensus sales forecast numbers centrally and provide visibility to the management team instantaneously.”

A leading producer of antibiotics and other pharmaceuticals, DSM Sinochem Pharmaceuticals aimed to repurpose working capital tied up in manual supply chain processes. With SAP IBP deployed in the cloud, the company was able to develop a single version of the truth for planning. This has helped to ease the manual workload for DSM’s supply chain managers while increasing agility when it comes to plan changes. One key measure of success so far: a 20% improvement in forecast accuracy over 3 years.

The list goes on

As a tool for transforming supply chains into agile demand networks for success in a digital economy, SAP IBP is helping companies all over the world blaze new trails. Already, we’ve covered industries in high tech, consumer products, pharmaceuticals, and metal and mining. But the list goes on.

Take, for example, a handful of customers with “international” in their names. Blount International – a manufacturer in the forestry, agriculture, and construction industries – has used SAP IBP for better analysis and forecasting in support of a build-to-stock model that has helped enhance customer fill rates, increase inventory turns, and reduce stock levels. Mondelēz International – one of the world's largest snacks companies – has created a single version of the truth that facilitates a “One Number” plan to align the entire organization. And Lennox International – a leader in HVAC and refrigeration – has increased supply chain transparency and efficiency, with results such as 80% better forecast accuracy and 90% less time needed for data collection.

Yes, when it comes to SAP IBP, the list goes on. The question is: Are you on it?

If not, think about coming to the 2018 SAPPHIRE NOW conference – where you’ll learn more about what SAP IBP can do to help your company compete more effectively in the digital economy. Last, year, we had Colgate, Corning, Hewlett Packard Enterprise, and Monsanto discuss their transformation stories live on stage.

For more statistics and insight on competing in the digital age, check out the new IDC infobrief, sponsored by SAP, Digital Business Planning Is at the Heart of Supply Chain Transformation

Labels:

1 Comment

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Business Trends

169 -

Business Trends

24 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

4 -

Expert Insights

12 -

Expert Insights

38 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

66 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

17

Related Content

- SAP Business Network for Logistics 2404 Release – What’s New? in Supply Chain Management Blogs by SAP

- SAP Named a Leader in the 2024 Gartner Magic Quadrant for Transportation Management Systems in Supply Chain Management Blogs by SAP

- SAP IBP Real-Time Integration: Empowering Businesses for Smarter, Faster Decisions in Supply Chain Management Blogs by SAP

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

- What's new with Collaborative Maintenance? in Supply Chain Management Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 10 | |

| 8 | |

| 6 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 2 |