- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Product Serialization in Business ByDesign - Part ...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Advisor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

02-28-2018

8:35 AM

Overview

This is the final blog on three part series on the use of serial numbers in Business ByDesign. This blog focuses on the use of serial numbers in Order To Cash business process, describes serial number inventory visibility & genealogy and related data sources and reports

Serial Numbers in Business Scenarios

Order To Cash

A typical Order To Cash process goes through the following steps:

Sales Order -> Delivery Proposal -> Goods Issue -> Outbound Delivery -> Customer Invoice -> Registered Product

This section shows various steps and ways to capture serial number during Order To Cash process.

Sales Order

A sales order is created with the items to be sold to a customer. This step is the same as for non-serialized items.

Delivery Proposal

A released customer demand generates a Delivery Proposal. When the order is ready to be picked, the delivery proposal is released to the warehouse to generate a pick ticket. This step is similar to the non-serialized inventory

Goods Issue

For serialized products, serial numbers are mandatory and actual quantity is incremented by entering the serial numbers.

The serial numbers can be entered i) manually in “Next Serial Number” field ii) uploaded via excel using “Upload” button iii) input via bar code scanning in the “Bar Code Input” tab

i) Manually entering serial number in “Next Serial Number” field

ii) Upload via Excel

A simple excel file with serial number column (without header) is created

The file is uploaded using the “Upload” button. This upload is performed per line item basis.

Outbound Delivery

Outbound delivery which is used for shipments, shows the Serial Numbers being shipped

Serial Numbers are also visible on Delivery Note

Customer Invoice

Serial Numbers are also carried over to Customer Invoice and are visible in Invoice Request

Registered Product

A registered product is created when serial number is created/ gnerated in the system. This could be at Goods Receipt or Make Production Task. Registered Product is updated with customer information at the time of Goods Issue. Registered Product captures the product warranty informaton and serial number movement tracking history showing Sales Order, Outbound Delivery, Production Lot, Purchase Order information.

Serial Number Inventory Visibility & Genealogy

This section describes the serial number inventory & genealogy reporting within the system

Serial Inventory Overview

Serial Inventory overview shows the snapshot of serial number inventory by product and logistics area. This screen can be navigated directly via Common Tasks -> Serial inventory Overview in Inbound Logistics, Outbound Logistics, Internal Logistics, Physical Inventory and Outbound Logistics Control or via Stock Overview -> Open Serial Inventory. Open Serial Inventory button is only active for serialized products

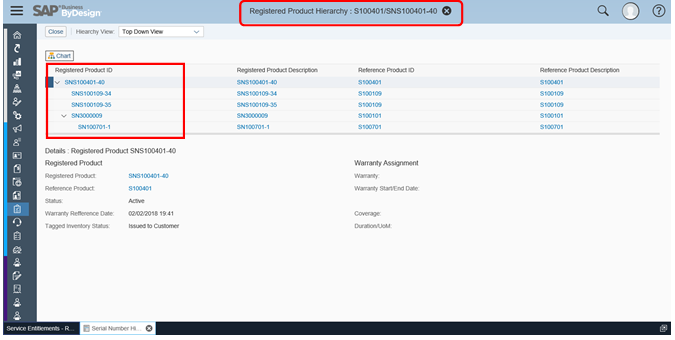

Registered Product Hierarchy (Genealogy)

Registered Product Hierarchy shows the hierarchy of serial numbers which have gone into making of parent serial number. Note this hierarchy only shows the serialized products.

Navigation: Service Entitlements -> Registered Products: Select the registered product -> Open Chart

Serial Number Data Sources & Reports

New data sources REG_PROD_GENERAL (Registered Product General Information) and REG_PROD_MH (Registered Product Movement History) are available to create serial number reports.

REG_PROD_GENERAL data source can be used to create flat parent- child serial number relationship report as shown below via Key User Tool.

REG_PROD_MH data source can be used to create serial number movement tracking report as shown below via Key User Tool.

Summary

In summary, this blog series serves as a quick start guide for using serial numbers in Business ByDesign. This blog series explained the required setup and configuration and showed the use of serial numbers in three major business process scenarios namely, Procure To Pay, Make To Stock and Order To Cash. As mentioned in Process Overview section serial number tracking is also supported in other scenarios like Over the Counter Sales, Third Party Delivery and Intra company stock transfer etc., which follow similar procedures. Lastly, it showed serial number tracking, tracing and reporting capabilities in Business ByDesign.

- SAP Managed Tags:

- SAP Business ByDesign

3 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

23 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

158 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,684 -

Product Updates

219 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

Related Content

- Cannot create a Single-date Order ECO using a custom OData service in Enterprise Resource Planning Q&A

- Define Bank Accounts to be Included in PEPPOL in Enterprise Resource Planning Q&A

- ISD (Input Service Distributer) GST registration in Enterprise Resource Planning Q&A

- Information about SAP Business ByDesign Partner Tenant Delivery in Enterprise Resource Planning Q&A

- SAP Business ByDesign 2023 year-end review and outlook 2024 in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 13 | |

| 11 | |

| 10 | |

| 7 | |

| 7 | |

| 6 | |

| 5 | |

| 5 | |

| 4 | |

| 4 |