- SAP Community

- Products and Technology

- CRM and Customer Experience

- CRM and CX Blogs by Members

- SAP IS-Retail: Replenishment VS Multi-step repleni...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

In IS-Retail new type of MRP/RP procedure has been introduced W - Replenishment (IS Retail) . At the beginning it’s worth to mention that it can be used only for stores and Customers and not for distribution centers. The solution is quite similar to MRP with reorder point or time phase planning but I leave it for you to decide at the end of this article.

Configuration starts with setting in article master. First decision is how inventory management is going to be used for replenishment.

Setting for type of inventory management to use.

In Replenishment, you have the option of using the detailed inventory management in Materials Management (MM). Alternatively, you can use Replenishment-Based Inventory Management, which is designed for a more simplified system. Recommended approach is to use as much as possible full MM oriented setting which is more accurate and allow more options (like ATP influence) in calculation of required quantity. On the other hand it has some limitations like the fact it can only be used on articles with value and quantity update. Second option is mandatory in case if you have articles managed on merchandise category basis (value-only article). Calculation of required quantity is much simpler comparing to MM option. Calculation logic is based only on stock on-hand (anticipated goods receipts might be taken into account if parameter Correct RS is set in article master data), which by simplifying means expected stock is equal to stock on-hand. In this article only MM oriented approach is presented.

Second step of configuration is setting up configuration data for store. As in Sap Manufacturing outcome of MRP is either internal production (production/process orders ) or external procurement (purchase requisition/schedule line for schedule agreement). In SAP Retail logic is a bit different and it’s important to decide what type of document is created as result of run of planning. This information comes from Store Order control parameters which is part of POS Inbound profile.

Store Order profile

As shown on the screenshot above, system decides what type of document to create based on source of processing (replenishment or store order) and type of source of supply assigned in article ( 1 – standard, external, 2 – internal, from distribution center). As mentioned before, Store Order profile is included in setting of POS inbound profile which is assigned to the site. If no assignment exist then system by default creates Sales Order type TAV (Standard Order (VMI)).

Assignment of POS Inbound profile to site

Additionally different POS Inbound profile can be assigned per merchandise category

Assignment of POS Inbound profile to site/merchandise category

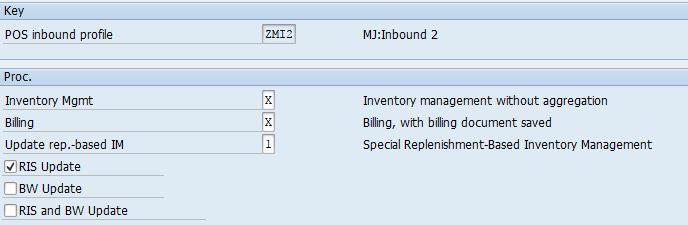

As mentioned POS Inbound profile consists of several settings including beside Store Order profile as well: Aggregated sales, Sales as per receipts which are used for inbound sales Idoc communication from POS systems (respectively Idocs: WPUUMS01, WPUBON01). Even if these settings are not so much important for “classic” replenishment but are very important for multi step replenishment.

POS Inbound profile - aggregated sales configuration

POS Inbound profile - sales per receipt configuration

In order to exclude articles that use Replenishment from standard requirements planning, the articles must be assigned RP procedure W (Replenishment (IS Retail)) via replenishment type.

Following replenishment (RP) types are used in SAP Retail.

- RP (replenishment)

- RF (replenishment with dynamic target stock)

- RS (time-phased replenishment)

- RR (time-phased replenishment with dynamic target stock)

Replenishment types RS and RR are same as respectively RP and RF beside they are used in Multi-step replenishment which is described later on.

The major difference between RP and RF is how target stock is calculated. RP type use static calculation and target stock value is set in logistic view of store in article master data. Future GR/GI or forecasted sales can be taken into account as an option. This approach is very similar to MRP procedure reorder point used in for example V1 or V2 MRP types. RF type use dynamic calculation by automatically calculating the target stock by totaling the predicted consumption values for the period today plus target range (replenishment parameter set in article master data in logistic view) of article and store concerned. Target stocks are determined on the basis of forecasted sales means, a forecast run is a prerequisite for this method.

Calculation example:

Article 906 has RP type RF(dynamic target stock) with target coverage 7 days. Current stock is 10EA. Forecast is done on weekly base for next 3 periods. Based on consumption following values forecast were calculated:

Forecasted values for article 906

Selection screen for replenishment program WRP1 :

- Rcpts/Issues (via ATP) – as name indicate and check rule is always set by system to RP.

- Include forecasted issues – valid only for static target stock determination, while dynamic always use it for calculations.

Replenishment run without determination of ATP and forecasted issues

Replenishment run with determination of ATP and without forecasted issues

Planning is run on 07/01 (Sunday) for next 7 days. Forecast for the article for whole week is 21EA. In this case target coverage period is 7 days means is equal to whole week but if coverage period would be 3 days then system should forecast quantity as 21EA (total forecast for period)/5 (number of working days) * 3 (number of working days to cover) = 12,6 EA (rounded to 13EA).

Based on settings in Store Order profile and source of supply of article, STO Purchase Order should be created as follow-on document.

Multi-Step Replenishment

Special form of Replenishment is multi-step replenishment where whole process has been divided into two or three steps. The purpose for it is mainly to increase performance by split of work as limitation it can only be used for stores. Replenishment includes a program for

- determining requirements calculation data - compile and save the master data required for requirements calculation.

- requirements calculations – determine requirements.

- generate follow-on documents – follow-on documents are generated.

Within multistep replenishment, the two-step procedure only uses the programs for requirements calculation and follow-on document creation. The program for determining the requirements calculation data is not used in the two-step procedure. The three-step procedure uses all three of the programs in multistep replenishment.

Following replenishment (RP) types are used in multi-step replenishment

- RS - time-phased replenishment with static target stock – reorder point

- RR - time-phased replenishment with dynamic target stock – target coverage

As in non multi-step replenishment for dynamic target stock, forecast is mandatory. Unlike for “classic” replenishment, multi-step uses its own sales forecast (POS history + sales forecast values) that is calculated using transaction WFCS01.

To be able to use multi-step replenishment POS Inbound profile needs to be update. This profile is assigned on site master data or in site/merchandise category level. For both Aggregated sales, Sales as per receipts field “Update replenishment-based inventory management” must be set to 1 – Special Replenishment-Based Inventory Management.

Process with example of calculation:

Article 906 for store ZSK4 is created.

- RP type RR is assigned.

- Planned delivery time is 1 day

- Source of supply 2 – stock transfer order

- Forecast period indication W- week

- Forecast historical periods 6

- Forecast period 3

- Target coverage 7 days

- Current stock 100EA

Sales data are sent from POS system via Idocs: aggregated transactions - WPUUMS01, Individual transactions: WPUBON0 1. (Tables WRPL,WRPT are updated).

POS Inbound monitor. GI not yet posted but available for sales forecast calculation

Calculation of forecasted sales (no goods issue is posted yet).

Display of consumption data and forecasted values. Sum of not posted consumption is 91EA

Inbound Idocs are reprocessed and GI is posted. Requirements calculation is run.

Results of requirements calculation run

Logic for determining target stock is the same as described above. Due to current stock is 9EA (Initially 100EA – 91 EA posted from POS Inbound Idocs) system calculated required quantity to 11 EA. In second (or third depending on approach) step transaction (WRSO) for generation of follow-on document is run. Based on settings in Store Order profile and source of supply of article, STO Purchase Order should be created as follow-on document.

Technical information:

- Tables WRPL, WRPT, WRPP

- Dynamic target quantity calculation

- SAP Managed Tags:

- Retail,

- SAP Retail Execution,

- MAN Material Requirements Planning

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

ABAP

1 -

API Rules

1 -

CRM

1 -

Custom Key Metrics

1 -

Customer Data

1 -

Determination

1 -

Determinations

1 -

Introduction

1 -

KYMA

1 -

Kyma Functions

1 -

open SAP

1 -

Sales and Service Cloud Version 2

1 -

Sales Cloud v2

1 -

SAP

1 -

SAP Community

1 -

SAP CPQ

1 -

SAP CRM Web UI

1 -

SAP Customer Data Cloud

1 -

SAP Customer Experience

1 -

SAP Integration Suite

1 -

SAP Sales Cloud v2

1 -

SAP Service Cloud v2

1 -

SAP Service Cloud Version 2

1 -

Service Cloud v2

1 -

Validation

1 -

Validations

1

- SAP Commerce Cloud Updates in 2023: A Not-So-Brief Summary for Technical Users in CRM and CX Blogs by SAP

- What's New in SAP Commerce Cloud - A Business User’s Perspective from Version 2211.0 Onward and Study Guide for the Stay Current Program in CRM and CX Blogs by SAP

- SAP Commerce Cloud’s Accelerated Innovation: The year in review and way forward in CRM and CX Blogs by SAP

- SAP Commerce Cloud Q3 ’23 Release Highlights in CRM and CX Blogs by SAP

- SAP DBM Module Intro in CRM and CX Blogs by Members