- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- #S4HANA 1709 use case series: 5b – Transportation ...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Advisor

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

10-12-2017

3:25 PM

Welcome to our next stop of our use case series. It is designed to offer a closer look at business value acceleration – driven by the design principles of SAP S/4HANA. The technology-induced implications of the digital economy are huge, though the technology itself is only a catalyst to achieve a fundamentally different business outcome.

The selected use cases, related to SAP S/4HANA Release 1709 are designed to emphasize and visualize the value behind this technological shift, that can be activated by you.

Now that we have seen what are the functional aspects of Transportation Management delivered with the SAP S/4HANA 1709 release in the last blog, we will today dive into the technical aspects.

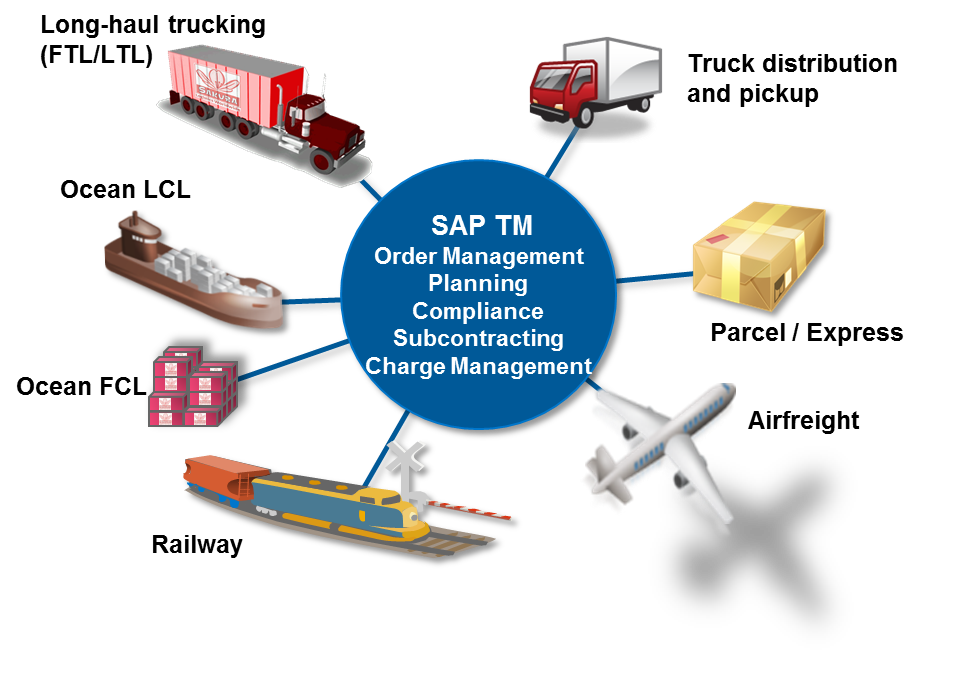

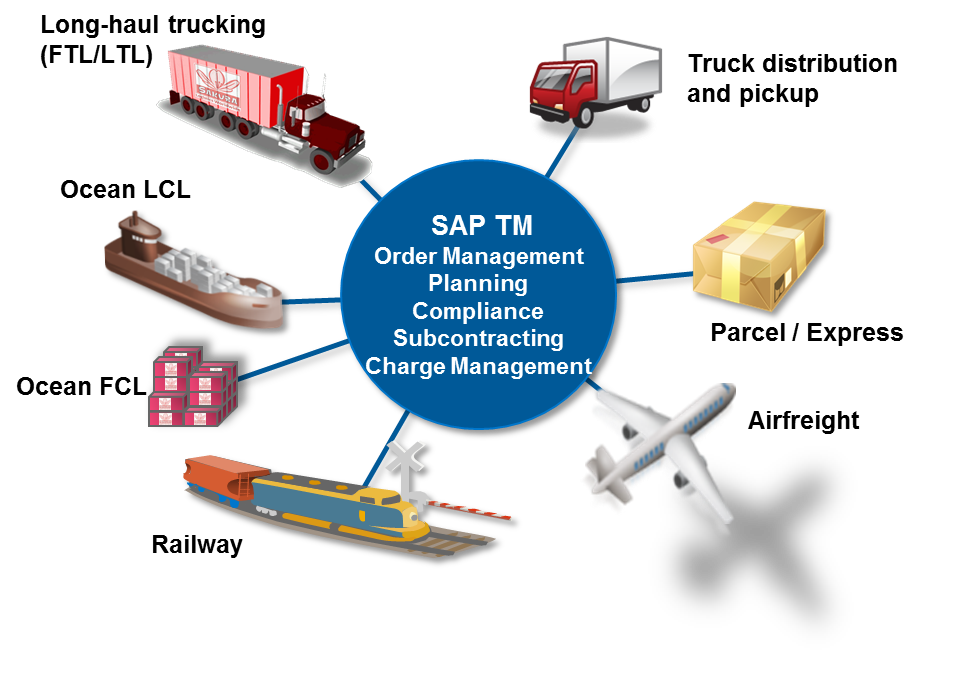

With the Transportation Management in SAP S/4HANA 1709 we deliver end to end processes for Shippers

With the 1709 release, we now have Transportation Management embedded in SAP S/4HANA based on feature scope contained in SAP TM 9.5 but focused on shippers. We provide system and process integration in SAP S/4HANA Enterprise Management, harmonize Business Partner, Locations and Product master data and provide user interface for SAP S/4HANA. Additionally, we can now work with real-time embedded analytics through the end to end process.

SAP Transportation Management embedded in SAP S/4HANA, offers modern transportation management to our customers, who want to leverage basic shipping functionality. The new deployment option also allows to run advanced transportation management processes embedded in SAP S/4HANA removing the necessity for costly data replication and additional hardware. Customer leveraging SAP TM in a hub scenario can of course continue to use the solution as “sidecar” as well.

As part of basic shipping, we have the processes for basic inventory, warehousing, and transportation. The following functionality is delivered as a result of this:

It is planned that all main shipper processes can be implemented with SAP S/4HANA Supply Chain for transportation management. As part of the embedded Transportation Management, we have advanced inventory, warehousing, and transportation*

A few foundation aspects enable real time transparency over information. You can create and use the central master data for transportation related processes as well. By embedding transportation management, product master and business partner can now be directly read without effort of integration. Additionally, you can use transportation specific data like transportation networks (for e.g. location, transportation lanes and default routes).

In the last blog I talked about automation and user experience. Let us deep dive further into the automation that bring effectiveness into the planning.

The main key features are order based transportation planning with subsequent creation of deliveries based on the transportation plan and automatic planning(optimization).

In planning, freight orders are created based on business documents, for example, forwarding orders. To do this, first freight units are created from the inbound business documents. Capacities are then assigned to these freight units. Various constraints are taken into account, for example, requested delivery dates. Freight orders are the result of the planning.

You can perform planning either manually or automatically based on profiles and settings. Several profiles and settings are available to make it easier to start interactive planning. With this, you can group planning relevant settings like capacities and planning costs. You can set time related or geographic selection attributes or set up optimizer, capacity selection, planning costs and settings for carrier selection or incompatibilities. Additional Freight Unit Building (FUB) rules help to consolidate freight units using FUB strategies. You can also set up ability to create Freight Orders automatically without a freight unit directly or through conditions. For the automatic Creation of Freight Units, the system groups all business document items under consideration of the following parameters:

You can use Manual planning or automate based on vehicle scheduling and routing (VSR) Optimization to generate optimized freight orders or you can generate multiple alternative transportation proposals for each freight unit and select the appropriate one. You initiate this from the interactive planning where you can assign freight units different capacities like Vehicle resources, Trailers (passive vehicle resource), Schedules or Freight bookings.

You can also perform VSR optimization in the background. Planning strategies enable you to control whether the system is to select a carrier immediately after VSR optimization, for example. You can also use planning strategies to define the planning steps that the system is to perform and the sequence in which it is to perform them (via customizing). Each planning strategy comprises one or more methods that represent the individual planning steps.

The aim of VSR optimization (VSR = vehicle scheduling and routing) is to assign freight units to capacities (for example, vehicle resources) in a cost-effective way while adhering to constraints, and to determine the sequence of deliveries and transportation dates/times. You can differentiate between hard and soft constraints. VSR optimization always adheres to hard constraints. You model soft constraints using penalty costs, for example, lateness costs that are part of the total costs.

VSR optimization generates a transportation plan consisting of planned freight orders from the optimization data (freight units and capacities). When doing this, it processes freight orders already available from a previous VSR optimization run or manual planning. VSR optimization inserts the freight units step-by-step into the transportation plan. Then VSR optimization modifies these initial solutions step-by-step, for example, by loading a freight unit on to another capacity or by changing the delivery sequence of a capacity. When doing this, the optimizer tries to minimize the total costs while adhering to the constraints. At the end of the planning run, VSR optimization returns the best solution found. For example, if the costs defined for non-delivery of a freight unit are lower than the costs for transporting the freight unit, the freight unit is not delivered.

Furthermore, you can generate multiple alternative transportation proposals, in other words, transportation plans, for each freight unit and can then choose to use one of them.

With this level of automation, the empowered user can focus on really strategic decisions allowing the system to automate based on pre-set conditions.

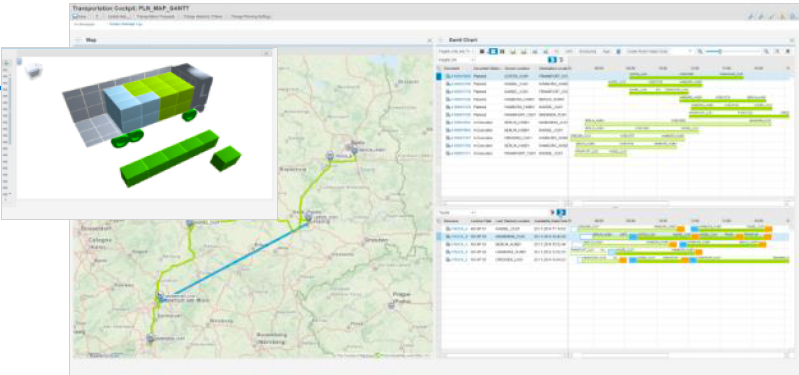

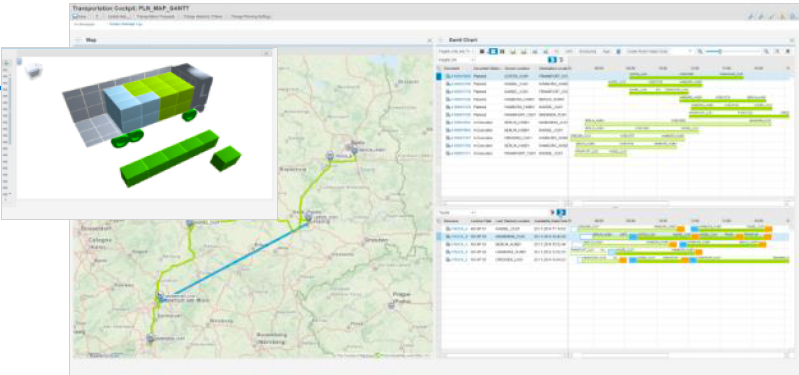

Finally, from a user experience perspective, the transportation cockpit enables you to trigger planning and provides interactive freight planning capabilities and status visibility. Additionally, Gantt chart provides a visual platform for performing interactive transportation planning and monitoring.

The Gantt chart, integrated into the transportation cockpit, interacts well with other existing functions. With this you have:

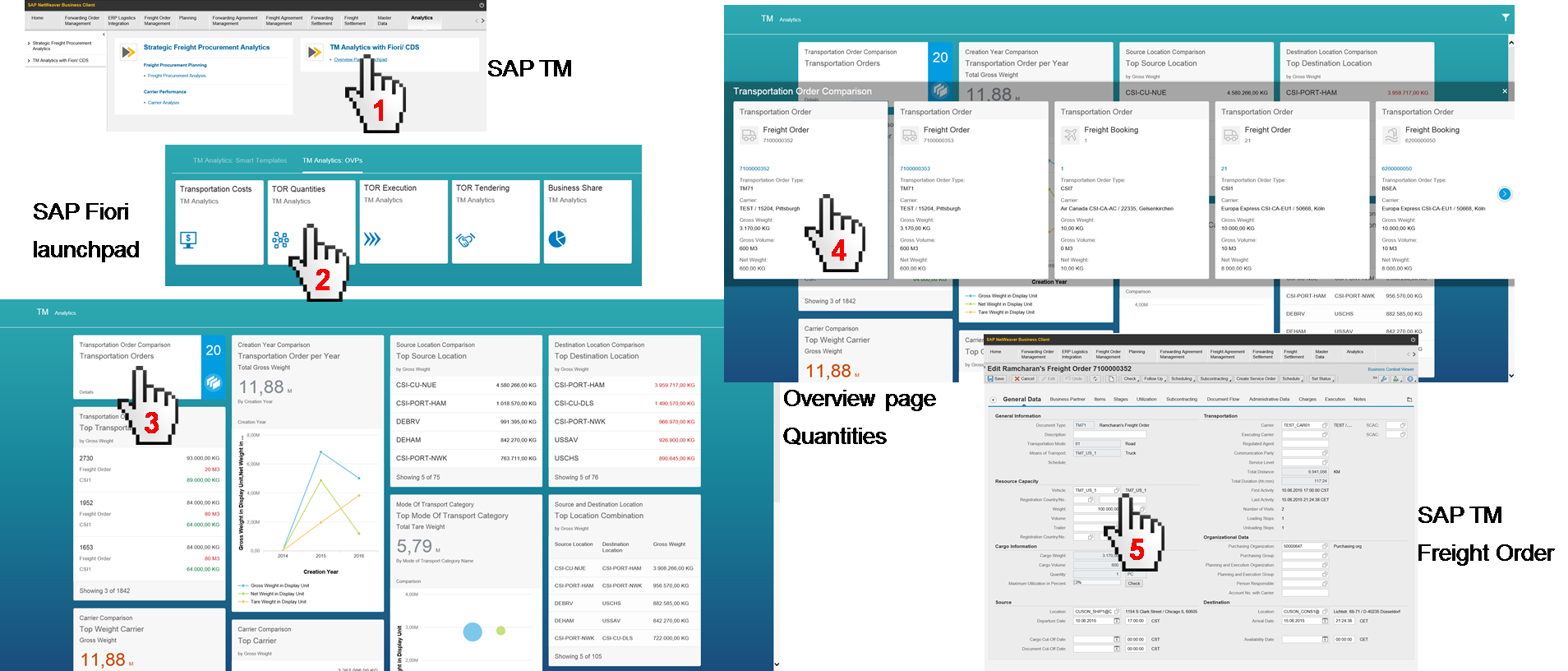

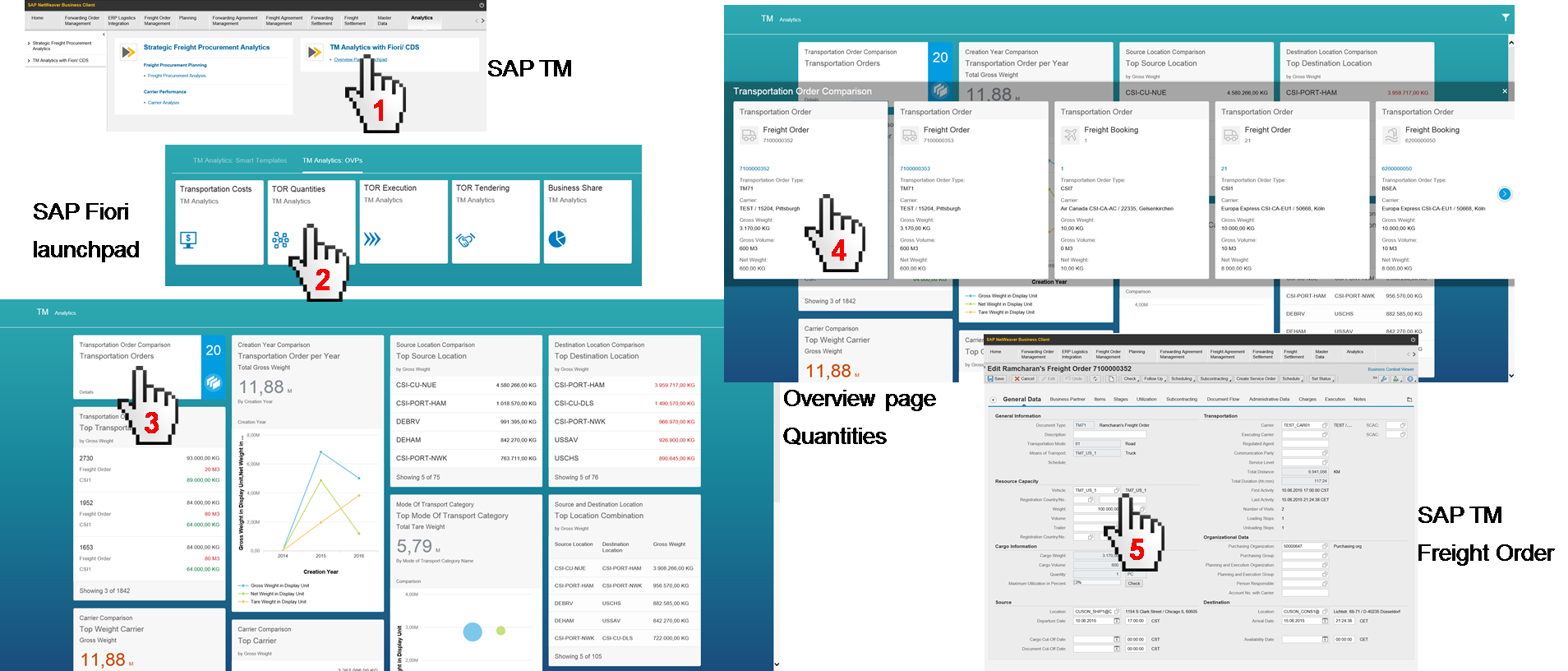

Finally, embedded Transportation Management analytics are provided with Core Data Services in SAP S/4HANA 1709.

What is the business value driven by this technology enablers?

With this automation using advanced planning algorithms, we can ensure that shippers can now have a cost-effective planning while keeping constraints under check. The optimized generation of transportation planning ensures consistency, lower risk while at the same time keeping the flexibility by enabling modifications. This not only builds up the trust of the customer but takes the shipper to a new level of service delivery with real time and seamless end to end process assured throughout the buying and selling cycle of the customer. The flexibility in planning optimized ensures intelligent, data-driven process delivering a very cost effective cross country transportation capabilities that also ensure lower costs of holding inventory.

With that we are at the end of this blog. I hope you liked today´s insights, watch out for the next use case soon.

All blog posts of this series can be found here

For more information on SAP S/4HANA, check out the following links:

SAP S/4HANA release info: www.sap.com/s4hana

And follow us via @SAP and #S4HANA or myself via @BeSchulze

The selected use cases, related to SAP S/4HANA Release 1709 are designed to emphasize and visualize the value behind this technological shift, that can be activated by you.

Now that we have seen what are the functional aspects of Transportation Management delivered with the SAP S/4HANA 1709 release in the last blog, we will today dive into the technical aspects.

With the Transportation Management in SAP S/4HANA 1709 we deliver end to end processes for Shippers

With the 1709 release, we now have Transportation Management embedded in SAP S/4HANA based on feature scope contained in SAP TM 9.5 but focused on shippers. We provide system and process integration in SAP S/4HANA Enterprise Management, harmonize Business Partner, Locations and Product master data and provide user interface for SAP S/4HANA. Additionally, we can now work with real-time embedded analytics through the end to end process.

SAP Transportation Management embedded in SAP S/4HANA, offers modern transportation management to our customers, who want to leverage basic shipping functionality. The new deployment option also allows to run advanced transportation management processes embedded in SAP S/4HANA removing the necessity for costly data replication and additional hardware. Customer leveraging SAP TM in a hub scenario can of course continue to use the solution as “sidecar” as well.

As part of basic shipping, we have the processes for basic inventory, warehousing, and transportation. The following functionality is delivered as a result of this:

- Main parts of the transportation network (except e.g. trade lane, allocations, business shares)

- Freight agreements

- Charge management (except e.g. air specific charges, event based chares, consolidated charge calculation)

- Separated inbound / Outbound freight order / Booking management based on deliveries

- Basic transportation planning (POWLs / manual freight unit selection)

- Transportation execution without event management

- Freight settlement management

- Basic agency billing

- Direct tendering for service agents (subcontracting)

- Dangerous goods management (except TM specific enhancements)

- TM output management

It is planned that all main shipper processes can be implemented with SAP S/4HANA Supply Chain for transportation management. As part of the embedded Transportation Management, we have advanced inventory, warehousing, and transportation*

- Strategic freight management

- Service product catalog (future topic)

- Service order management (future topic)

- Forwarding management / Settlement (future topic)

- Inbound and outbound freight management based on sales orders, purchase orders, deliveries, stock transfer orders and returns

- Planning

- Driver management

- Advanced charge calculation

- Carrier / Service billing

- Group logistics management (future topic)

- Harmonized transportation scheduling (future topic)

- SAP EWM integration (via services)

- TM analytics

A few foundation aspects enable real time transparency over information. You can create and use the central master data for transportation related processes as well. By embedding transportation management, product master and business partner can now be directly read without effort of integration. Additionally, you can use transportation specific data like transportation networks (for e.g. location, transportation lanes and default routes).

In the last blog I talked about automation and user experience. Let us deep dive further into the automation that bring effectiveness into the planning.

The main key features are order based transportation planning with subsequent creation of deliveries based on the transportation plan and automatic planning(optimization).

In planning, freight orders are created based on business documents, for example, forwarding orders. To do this, first freight units are created from the inbound business documents. Capacities are then assigned to these freight units. Various constraints are taken into account, for example, requested delivery dates. Freight orders are the result of the planning.

You can perform planning either manually or automatically based on profiles and settings. Several profiles and settings are available to make it easier to start interactive planning. With this, you can group planning relevant settings like capacities and planning costs. You can set time related or geographic selection attributes or set up optimizer, capacity selection, planning costs and settings for carrier selection or incompatibilities. Additional Freight Unit Building (FUB) rules help to consolidate freight units using FUB strategies. You can also set up ability to create Freight Orders automatically without a freight unit directly or through conditions. For the automatic Creation of Freight Units, the system groups all business document items under consideration of the following parameters:

- Hard constraints (source location and destination location as well as pick-up and delivery dates)

- Business document attributes and packaging information

- Incompatibilities

- FUB rules

You can use Manual planning or automate based on vehicle scheduling and routing (VSR) Optimization to generate optimized freight orders or you can generate multiple alternative transportation proposals for each freight unit and select the appropriate one. You initiate this from the interactive planning where you can assign freight units different capacities like Vehicle resources, Trailers (passive vehicle resource), Schedules or Freight bookings.

You can also perform VSR optimization in the background. Planning strategies enable you to control whether the system is to select a carrier immediately after VSR optimization, for example. You can also use planning strategies to define the planning steps that the system is to perform and the sequence in which it is to perform them (via customizing). Each planning strategy comprises one or more methods that represent the individual planning steps.

The aim of VSR optimization (VSR = vehicle scheduling and routing) is to assign freight units to capacities (for example, vehicle resources) in a cost-effective way while adhering to constraints, and to determine the sequence of deliveries and transportation dates/times. You can differentiate between hard and soft constraints. VSR optimization always adheres to hard constraints. You model soft constraints using penalty costs, for example, lateness costs that are part of the total costs.

VSR optimization generates a transportation plan consisting of planned freight orders from the optimization data (freight units and capacities). When doing this, it processes freight orders already available from a previous VSR optimization run or manual planning. VSR optimization inserts the freight units step-by-step into the transportation plan. Then VSR optimization modifies these initial solutions step-by-step, for example, by loading a freight unit on to another capacity or by changing the delivery sequence of a capacity. When doing this, the optimizer tries to minimize the total costs while adhering to the constraints. At the end of the planning run, VSR optimization returns the best solution found. For example, if the costs defined for non-delivery of a freight unit are lower than the costs for transporting the freight unit, the freight unit is not delivered.

Furthermore, you can generate multiple alternative transportation proposals, in other words, transportation plans, for each freight unit and can then choose to use one of them.

With this level of automation, the empowered user can focus on really strategic decisions allowing the system to automate based on pre-set conditions.

Finally, from a user experience perspective, the transportation cockpit enables you to trigger planning and provides interactive freight planning capabilities and status visibility. Additionally, Gantt chart provides a visual platform for performing interactive transportation planning and monitoring.

The Gantt chart, integrated into the transportation cockpit, interacts well with other existing functions. With this you have:

- Transparent availability of resources and drivers and visibility of utilization of resources

- Option to display or hide document separators, time windows or display and solve warnings

- Insights into planning and execution status of documents and transportation activities

- Ability to have flexible and dynamic switch between different views, personalize table area appearance, configure visualization of notifications

- Interactive planning in the Gantt chart

Finally, embedded Transportation Management analytics are provided with Core Data Services in SAP S/4HANA 1709.

What is the business value driven by this technology enablers?

With this automation using advanced planning algorithms, we can ensure that shippers can now have a cost-effective planning while keeping constraints under check. The optimized generation of transportation planning ensures consistency, lower risk while at the same time keeping the flexibility by enabling modifications. This not only builds up the trust of the customer but takes the shipper to a new level of service delivery with real time and seamless end to end process assured throughout the buying and selling cycle of the customer. The flexibility in planning optimized ensures intelligent, data-driven process delivering a very cost effective cross country transportation capabilities that also ensure lower costs of holding inventory.

With that we are at the end of this blog. I hope you liked today´s insights, watch out for the next use case soon.

All blog posts of this series can be found here

For more information on SAP S/4HANA, check out the following links:

SAP S/4HANA release info: www.sap.com/s4hana

And follow us via @SAP and #S4HANA or myself via @BeSchulze

- SAP Managed Tags:

- SAP S/4HANA

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

20 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

23 -

Expert Insights

114 -

Expert Insights

150 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,687 -

Product Updates

202 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

85

Related Content

- SAP ERP Functionality for EDI Processing: UoMs Determination for Inbound Orders in Enterprise Resource Planning Blogs by Members

- How to Create Outbound Delivery With order reference in SAP VL01N in Enterprise Resource Planning Blogs by Members

- Creation of Outbound Delivery using VL01N in SAP in Enterprise Resource Planning Q&A

- SAP S/4HANA Cloud Extensions with SAP Build Best Practices: An Expert Roundtable in Enterprise Resource Planning Blogs by SAP

- Deep Dive into SAP Build Process Automation with SAP S/4HANA Cloud Public Edition - Retail in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 5 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 3 | |

| 2 |