- SAP Community

- Products and Technology

- Technology

- Technology Blogs by SAP

- New IoT-Based Services for Manufacturing leveragin...

Technology Blogs by SAP

Learn how to extend and personalize SAP applications. Follow the SAP technology blog for insights into SAP BTP, ABAP, SAP Analytics Cloud, SAP HANA, and more.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

08-11-2017

12:13 PM

Introduction

You might have seen the press announcement about the new IoT-based services for manufacturing leveraging the SAP Cloud Platf... by Mitsubishi Electric and SAP, which has been published already earlier this year during the industrial trade show Hannover Messe 2017. Since these IoT-based services for manufacturing running on top of the SAP Cloud Platform Internet of Things (IoT) are currently being extended, e. g. by building further common IoT scenarios and preparing for the next Hannover Messe 2018, I would like to take the opportunity to provide you here further details about the technical foundation of these IoT-based services and what are some of the upcoming milestones.

SAP Cloud Platform IoT

IoT is one of the hot topics at SAP, and there have been published several announcements around the strategic importance of IoT at SAP, such as how SAP IoT connects the world to enable live business as well as the introduction of the SAP Leonardo IoT Portfolio. In this context to support customers in their journey towards IoT SAP has made already mid of 2016 the acquisition of the IoT company PLAT.ONE. The enterprise-grade IoT platform of PLAT.ONE has been fully integrated into the SAP Cloud Platform and is generally available since May 2017 as SAP Cloud Platform IoT for the Cloud Foundry Environment. Some of the key capabilities of this next generation SAP Cloud Platform IoT are the following:

- Lifecycle management at scale for IoT devices from onboarding to decommissioning

- Secure and reliable connection to remote devices over a broad variety of IoT protocols

- Collect and process sensor data at scale already at the edge or in the cloud and store it on SAP Cloud Platform for the use by other applications

- Unique multi-tenant model as well as a semantic data model with dynamic properties and role-based views and authorizations

- Enterprise grade edge processing capabilities including guaranteed delivery from edge to cloud, buffering of data at the edge when not connected, scheduled / on-demand / batched delivery, remote software / device firmware upgrades, complex rules to define threshold values and trigger alarms when threshold values are exceeded

- Bi-directional communication of sensor data or commands from device over the edge to the cloud and vice versa

You can read further details about the key functions and benefits of SAP Cloud Platform IoT for example on the SAP Internet of Things Community, the user documentation, and the Q3 / 2017 update of the SAP Cloud Platform Essentials.

Mitsubishi Electric Automation Solutions

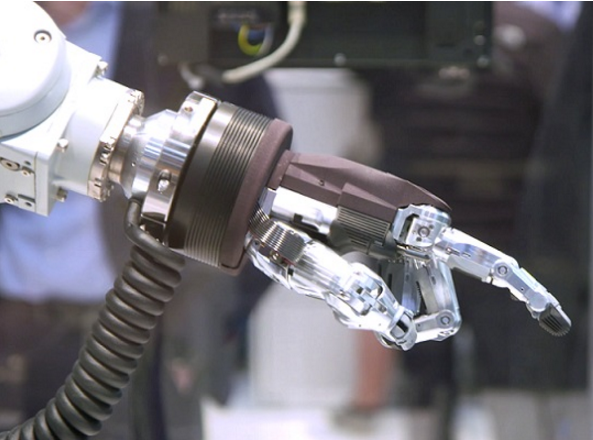

Mitsubishi Electric is one of the world’s leading manufactures of electrical and electronic products used in a broad range of fields and applications. The products of Mitsubishi Electric are for example in the area of automotive equipment, building systems, such as photovoltaic systems and elevators (see for example the Mitsubishi Electric-owned Solae Test Tower as the world’s tallest elevator testing tower) , power generation systems, large-scale visual information systems (e. g. huge LCD screens), space systems, such as satellite components, optical and radio telescopes (see Atacama Large Millimeter Array observatory, one of the world’s most advanced telescopes, equipped wi...), factory automation systems, such as industrial robots, and many more.

One of the key challenges for Mitsubishi Electric is how to transfer sensor data from its automation solutions to the SAP systems of their customers. And more and more customers require a tighter integration of Mitsubishi Electric's e‑F@ctory solutions with their SAP applications, e. g. to have live insights into the connected automation systems with up to date information about the health status & usage, as well as predictive analytics in order to trigger alerts and maintenance request in case threshold values are exceeded.

Cooperation between Mitsubishi Electric and SAP

In order to solve the challenges described above Mitsubishi Electric and SAP collaborated with each other and evaluated how SAP Cloud Platform IoT can be leveraged to provide a solution to both of our customers. Within this cooperation Mitsubishi Electric and SAP build an end-to-end use case scenario, in which one of the automation systems of Mitsubishi Electric is connected to the SAP Cloud Platform IoT in order to send sensor data from the robot via SAP Cloud Platform IoT to SAP applications, such as SAP PdMS (SAP Predictive Maintenance and Service) and SAP AIN (SAP Asset Intelligence Network). One of the key focus areas of this show case is the “After Sales Market”, i. e. everything around maintenance requests, ordering of spare parts, up & cross selling, field services, support etc. In the demo scenario a Mitsubishi Electric automation system is connected to the SAP Cloud Platform IoT for a bi-directional integration between the robot and the SAP Cloud Platform IoT. The Mitsubishi automation system is connected to the SAP Cloud Platform IoT via the communication protocol HTTP / REST, and integrated with SAP PdMS via SAP Cloud Platform Integration. Based on rules and alarms, which can be flexibly configured within the SAP Cloud Platform IoT, e. g. the remaining grease time is too low or belt is broken, a maintenance request can be triggered in SAP PdMS. The ticket number from SAP PdMS is sent back to the Mitsubishi automation equipment and can be viewed in a display on the device. In the demo show case up to 1000 different sensor data per second are sent from the Mitsubishi automation system to SAP Cloud Platform IoT, and also up to 1000 different data / commands per second are sent from SAP Cloud Platform IoT back to the Mitsubishi equipment. During the entire set up of this show case the SAP Cloud Platform IoT proofed to be highly reliable and performant, so that sensor data of 100000 per second and more could have been handled easily by the platform as well. The sensor data, that are sent from the Mitsubishi automation system to SAP Cloud Platform IoT, contain for example remaining grease time, amperage values, remaining belt time or error codes at different points on the device. The data, that are sent from the SAP Cloud Platform IoT to the Mitsubishi equipment, contain for example ticket number, order number, information about the service status from SAP PdMS etc.

The successful implementation of this end-to-end use case laid the foundation for the above mentioned press announcement about the new IoT-based services for manufacturing leveraging the SAP Cloud Platf... by Mitsubishi Electric and SAP. The demo scenario was shown for the first time in public at the Hannover Messe 2017 , for example right away on the first day of the event to board members of both Mitsubishi Electric as well as SAP.. Mr. Thomas Lantermann, Senior Solution Consultant FA EMEA, Factory Automation, European Business Group, Mitsubishi Electric, was one of the key contact persons during the implementation of the demo scenario and also one of the key presenters of this use case at the Hannover Fair. One of the quotes from Mr. Lantermann about the key benefits of this partnership is: "With the help of SAP Cloud Platform IoT we can on-board and manage our automation systems from Mitsubishi Electric in a fast and efficient way. In particular the immediate visualization of the sensor data without any coding, the secure communication from devices to the cloud, and also tight and smooth integration of relevant data into any backend application are key advantages of the SAP Cloud Platform". The end-to-end use case was shown after the Hannover Fair also at multiple other conferences, such as the SAP Leonardo Live Event in July 2017 Frankfurt.

Leveraging the SAP Cloud Platform IoT Mitsubishi Electric can transfer data from its automation solutions to the SAP Cloud Platform , and from here to any SAP and non-SAP system. With this Mitsubishi Electric is now able to extend its solutions to lay the foundation for partners and customers to offer value-added IoT-based services in the manufacturing and process industry sectors. The integration of Mitsubishi Electric automation equipment with SAP Cloud Platform IoT enables Mitsubishi Electric for new IoT-based services, including remote device and connectivity management, monitoring of production status and asset availability, as well as predictive maintenance, to allow operators to benefit from long-term analysis of factory data.

The press announcement about the new IoT-based services for manufacturing leveraging the SAP Cloud Platf... also includes the following quote from Mr. Pütz, president of Factory Automation – European Business Group, Mitsubishi Electric Europe: “Mitsubishi Electric has long provided leading-edge technologies for the collection of production information, and now our partnership with SAP enables our customers to easily connect with SAP Cloud Platform. Here, our e-F@ctory Alliance partner, SAP, provides tools and applications to enable users to utilize production information to the fullest extent.”

SAP Cloud Platform IoT at your finger tips: Summary and next steps

The SAP Cloud Platform IoT technology provides companies, such as Mitsubishi Electric, the ability to integrate information from their machines and devices to basically any SAP and non-SAP system, which is a tremendous benefit for these companies and their clients. The main reason for this is that basically all the customers of companies, such as Mitsubishi Electric, use SAP applications and require a tighter integration of the sensors and machines for exactly those maintenance scenarios, for which the demo use case described in this blog was built.

Since the end-to-end demo scenario is great success with very good feedback and demand from so many customers, it will b continued to be presented at various events and conferences, such as the e-Factory Alliance Forum of Mitsubishi Electric in Ratingen, Germany. Furthermore it is planned to have this end-to-end use case permanently set up in one of the customer areas at one of the SAP office buildings in Walldorf, Germany. Last but not least, the planning for the Hannover Messe 2018 started already, and for this upcoming industrial trade show in Hannover it is planned to extend the end-to-end demo scenario by including the triggering of software updates on a device via SAP Cloud Platform IoT. This means that SAP Cloud Platform IoT will be leveraged in order to push software updates to a connected machine. SAP Cloud Platform IoT can receive the software update from for example a connected SAP application, such as the SAP Asset Intelligence Network; therefore it is also planned that the required configuration of software components in the SAP Asset Intelligence Network will be included into this system. So there are quite some exciting activities planned in the near future for this end-to-end use case leveraging SAP Cloud Platform IoT, kindly stay tuned!

- SAP Managed Tags:

- Cloud Integration,

- SAP Business Technology Platform

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

ABAP CDS Views - CDC (Change Data Capture)

2 -

AI

1 -

Analyze Workload Data

1 -

BTP

1 -

Business and IT Integration

2 -

Business application stu

1 -

Business Technology Platform

1 -

Business Trends

1,658 -

Business Trends

91 -

CAP

1 -

cf

1 -

Cloud Foundry

1 -

Confluent

1 -

Customer COE Basics and Fundamentals

1 -

Customer COE Latest and Greatest

3 -

Customer Data Browser app

1 -

Data Analysis Tool

1 -

data migration

1 -

data transfer

1 -

Datasphere

2 -

Event Information

1,400 -

Event Information

66 -

Expert

1 -

Expert Insights

177 -

Expert Insights

296 -

General

1 -

Google cloud

1 -

Google Next'24

1 -

Kafka

1 -

Life at SAP

780 -

Life at SAP

13 -

Migrate your Data App

1 -

MTA

1 -

Network Performance Analysis

1 -

NodeJS

1 -

PDF

1 -

POC

1 -

Product Updates

4,577 -

Product Updates

342 -

Replication Flow

1 -

RisewithSAP

1 -

SAP BTP

1 -

SAP BTP Cloud Foundry

1 -

SAP Cloud ALM

1 -

SAP Cloud Application Programming Model

1 -

SAP Datasphere

2 -

SAP S4HANA Cloud

1 -

SAP S4HANA Migration Cockpit

1 -

Technology Updates

6,873 -

Technology Updates

420 -

Workload Fluctuations

1

Related Content

- Support for API Business Hub Enterprise in Actions Project in Technology Blogs by SAP

- IoT - Ultimate Data Cyber Security - with Enterprise Blockchain and SAP BTP 🚀 in Technology Blogs by Members

- Partner-2-Partner Collaboration in Manufacturing in Technology Blogs by SAP

- SAP Datasphere - Space, Data Integration, and Data Modeling Best Practices in Technology Blogs by SAP

- Integrating with SAP Datasphere Consumption APIs using SAML Bearer Assertion in Technology Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 37 | |

| 25 | |

| 17 | |

| 13 | |

| 7 | |

| 7 | |

| 7 | |

| 6 | |

| 6 | |

| 6 |