- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Production Planning in a cross plant set-up

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

hammadulhaq

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

06-26-2017

5:06 PM

Hello everyone,

This document explains the steps required to configure a system for Production planning in a cross plant set-up. Many members post questions with a bit of variation regarding this scenario. Hopefully this blog will address any current and future queries regarding this topic.

Scenario:

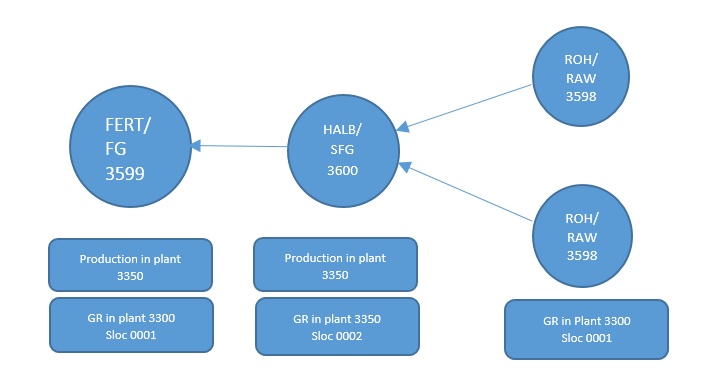

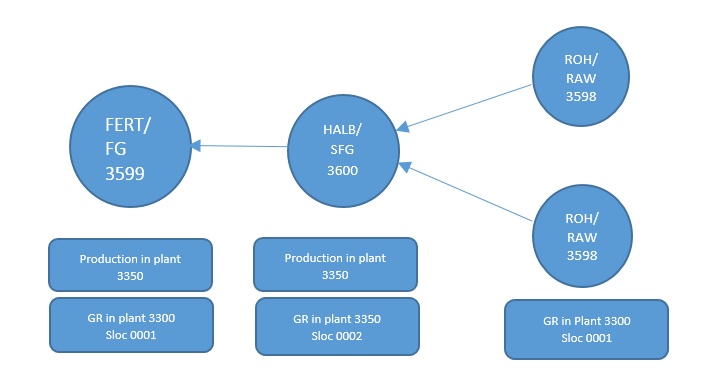

Cross plant production is one of the key parts of SAP – Production Planning. It is also know as production in an alternative plant. In this document we will use Special procurement types 70 and 80 to address this scenario, thus eliminating the need of doing any transfer postings.

Prerequisites – Create Master Data i.e.

Material Master (FERT, HALB and ROH)

BOM (FERT and HALB)

Routing (FERT and HALB)

Work Centers

HALB will be created in 3350 plant, while FERT and ROH will exist in both plants(3350 and 3300) by extending them through MM01.

We will be working on MTS – Make to Stock strategy.

Only configuration required in this scenario is to configure special procurement types 70 and 80.

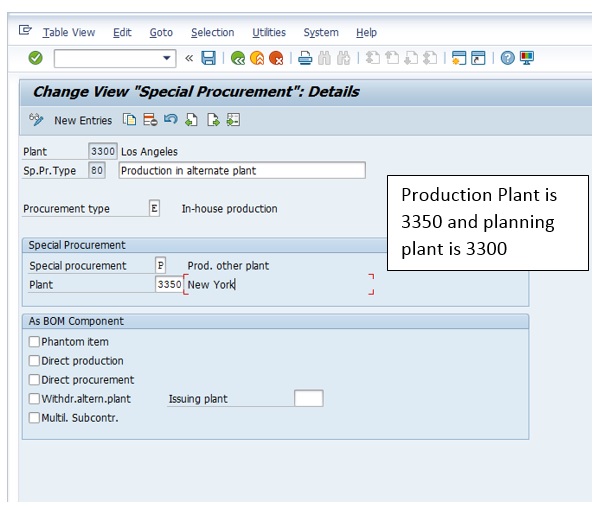

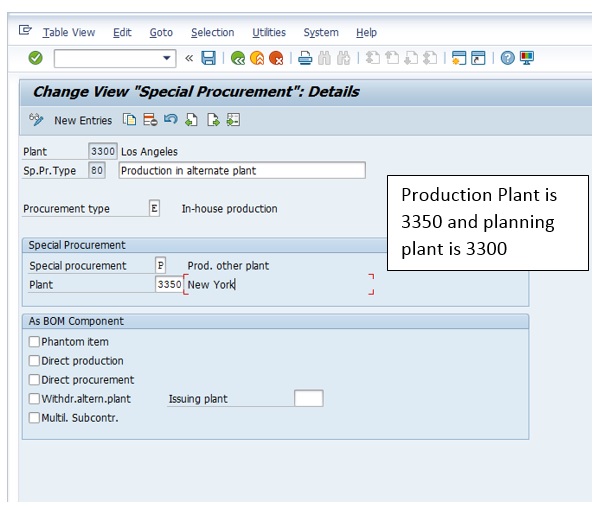

For plant 3300 we will use special procurement type 80. We will mention plant 3350 in special procurement section of [ Prod. Other plant ].

For plant 3350 we will use special procurement type 70. We will mention plant 3300 as issuing plant in the ‘As BOM component’ section. Make sure there’s a tick at the box of withdr.altern.plant (withdrawal from alternate plant).

Special procurement 70 will be assigned to HALB’s BOM component. We will select ROH material in the BOM and click on item (or press F7). T.Code CS02

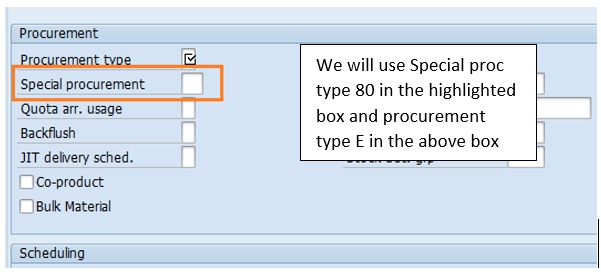

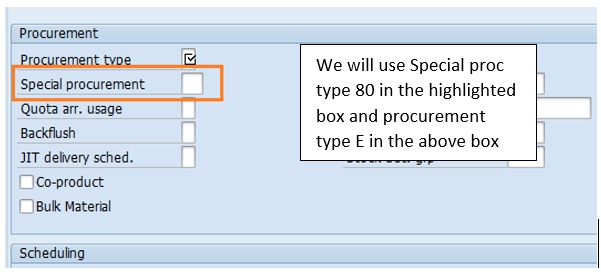

Special procurement 80 will be assigned in FERT’s MRP 2 view in plant 3300. T.Code MM02

After completing all of the above tasks we will proceed with a real time test. For FERT material, stock of 50 already exists thus we will have to add this in our future calculations.

Now we will go to PIR planning table T.code MD61, and enter the value of 100. Make sure the date is not on a holiday.

You can double check the planned qty and its date in Schedule lines tab.

After running the MRP (T.Code MD02) we will go to stock requirement list of FERT material. Here you can see IndReq of 100 and planned order of 50 quantity. Reason being that 50 qty of FERT is already available in unrestricted stock, so that stock will be consumed first. You can also see supplying plant as 3350 because FERT material will be manufactured in plant 3350.

For FERT Material in plant 3350 (T.code MD04) you can see Planned order for 50 qty while 3300 plant is showing as planning plant.

For HALB Material in plant 3350 you can see a planned order of quantity 50.

For ROH Material you can see DepReq of 100 and PurRqs of 100. That’s because in one HALB material 2 ROH materials are consumed.

Convert Purchase requisition of ROH to purchase order and do GR in plant 3300.

Convert planned order of HALB to production order.

In component overview of HALB’s production order you can see 3300 plant for ROH material.

Now we will do goods issuance (Movement type 261) on the production order of HALB material.

Before Goods issuance, ROH material stock is 100.

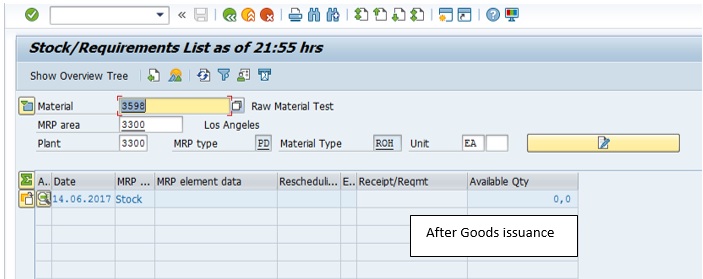

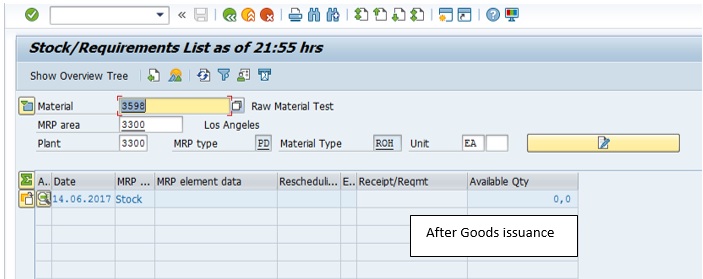

After Goods issuance, ROH material stock reduces to zero. Point to notice is that there were no transfer postings done.

After doing Confirmation of HALB’s production order we will do Goods Receipt of HALB material.

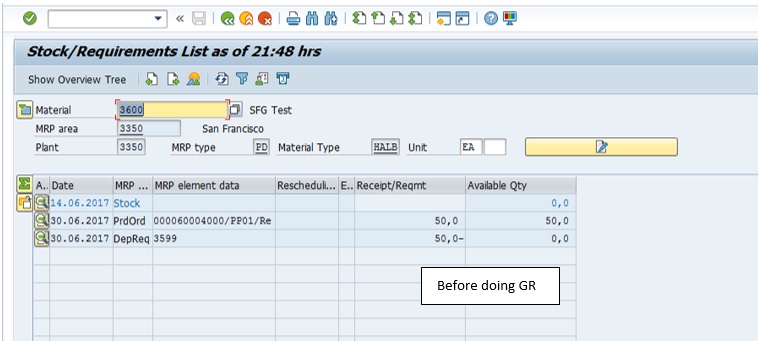

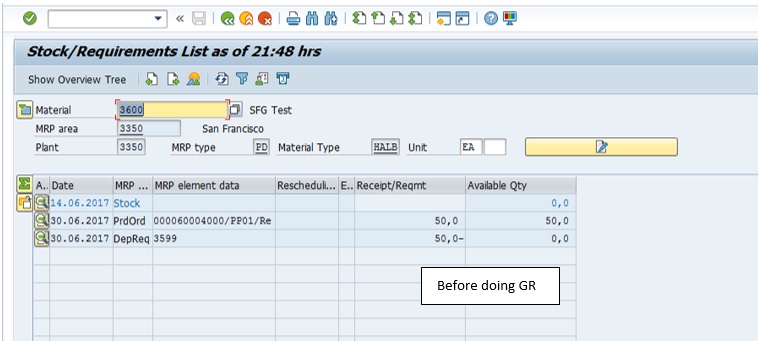

Before GR of HALB

After GR of HALB. 50 quantity has been added to stock.

After GR of HALB material, we will convert planned order of FERT to Production order. Note supplying plant is 3350.

Planning plant and MRP area for FERT’s production order is coming as 3300

Now we will do goods issuance to FERT’s production order. 261 movement type is done.

In stock/requirements list (T.Code MD04) for HALB you can see the effects of GI

In FERT material’s Production order HALB’s withdrawal quantity is coming as 50

After confirmation of production order we will do GR of FERT material.

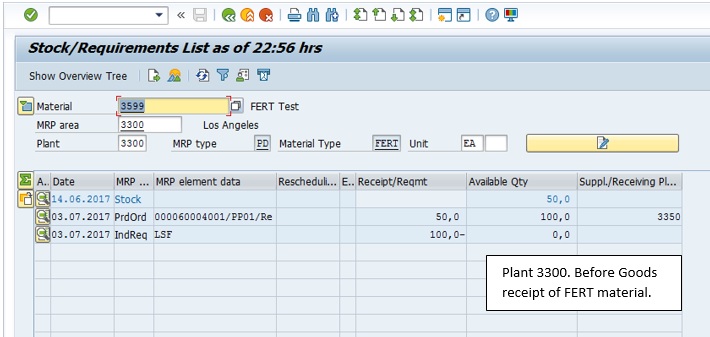

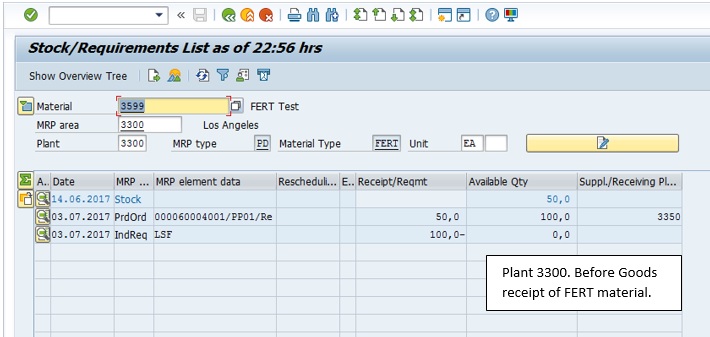

But before that you can see for plant 3300, FERT’s material Stock/requirement list is showing 3350 as supplying plant while for plant 3350 Stock/requirement list is showing 3300 as planning plant.

We will go to MIGO and do GR of FERT’s production order. It will be done directly to 3300 plant 0001 Sloc without the need of any transfer postings.

After GR, stock in 3300 plant has increased from 50 to 100

After GR, stock in 3350 plant has decreased to zero.

You can see in Stock overview list (T.Code MMBE) that stock in ‘unrestricted use’ is 100 for plant 3300 in 0001 Sloc, while stock is Zero for plant 3350. Production Cost will be collected in production plant 3350.

There are numerous scenarios for Multi Plant Planning, I hope this blog has established a baseline understanding of how Multi Plant Planning works.

If you have any queries please feel free to ask.

This document explains the steps required to configure a system for Production planning in a cross plant set-up. Many members post questions with a bit of variation regarding this scenario. Hopefully this blog will address any current and future queries regarding this topic.

Scenario:

Cross plant production is one of the key parts of SAP – Production Planning. It is also know as production in an alternative plant. In this document we will use Special procurement types 70 and 80 to address this scenario, thus eliminating the need of doing any transfer postings.

Prerequisites – Create Master Data i.e.

Material Master (FERT, HALB and ROH)

BOM (FERT and HALB)

Routing (FERT and HALB)

Work Centers

HALB will be created in 3350 plant, while FERT and ROH will exist in both plants(3350 and 3300) by extending them through MM01.

We will be working on MTS – Make to Stock strategy.

Only configuration required in this scenario is to configure special procurement types 70 and 80.

For plant 3300 we will use special procurement type 80. We will mention plant 3350 in special procurement section of [ Prod. Other plant ].

For plant 3350 we will use special procurement type 70. We will mention plant 3300 as issuing plant in the ‘As BOM component’ section. Make sure there’s a tick at the box of withdr.altern.plant (withdrawal from alternate plant).

Special procurement 70 will be assigned to HALB’s BOM component. We will select ROH material in the BOM and click on item (or press F7). T.Code CS02

Special procurement 80 will be assigned in FERT’s MRP 2 view in plant 3300. T.Code MM02

After completing all of the above tasks we will proceed with a real time test. For FERT material, stock of 50 already exists thus we will have to add this in our future calculations.

Now we will go to PIR planning table T.code MD61, and enter the value of 100. Make sure the date is not on a holiday.

You can double check the planned qty and its date in Schedule lines tab.

After running the MRP (T.Code MD02) we will go to stock requirement list of FERT material. Here you can see IndReq of 100 and planned order of 50 quantity. Reason being that 50 qty of FERT is already available in unrestricted stock, so that stock will be consumed first. You can also see supplying plant as 3350 because FERT material will be manufactured in plant 3350.

For FERT Material in plant 3350 (T.code MD04) you can see Planned order for 50 qty while 3300 plant is showing as planning plant.

For HALB Material in plant 3350 you can see a planned order of quantity 50.

For ROH Material you can see DepReq of 100 and PurRqs of 100. That’s because in one HALB material 2 ROH materials are consumed.

Convert Purchase requisition of ROH to purchase order and do GR in plant 3300.

Convert planned order of HALB to production order.

In component overview of HALB’s production order you can see 3300 plant for ROH material.

Now we will do goods issuance (Movement type 261) on the production order of HALB material.

Before Goods issuance, ROH material stock is 100.

After Goods issuance, ROH material stock reduces to zero. Point to notice is that there were no transfer postings done.

After doing Confirmation of HALB’s production order we will do Goods Receipt of HALB material.

Before GR of HALB

After GR of HALB. 50 quantity has been added to stock.

After GR of HALB material, we will convert planned order of FERT to Production order. Note supplying plant is 3350.

Planning plant and MRP area for FERT’s production order is coming as 3300

Now we will do goods issuance to FERT’s production order. 261 movement type is done.

In stock/requirements list (T.Code MD04) for HALB you can see the effects of GI

In FERT material’s Production order HALB’s withdrawal quantity is coming as 50

After confirmation of production order we will do GR of FERT material.

But before that you can see for plant 3300, FERT’s material Stock/requirement list is showing 3350 as supplying plant while for plant 3350 Stock/requirement list is showing 3300 as planning plant.

We will go to MIGO and do GR of FERT’s production order. It will be done directly to 3300 plant 0001 Sloc without the need of any transfer postings.

After GR, stock in 3300 plant has increased from 50 to 100

After GR, stock in 3350 plant has decreased to zero.

You can see in Stock overview list (T.Code MMBE) that stock in ‘unrestricted use’ is 100 for plant 3300 in 0001 Sloc, while stock is Zero for plant 3350. Production Cost will be collected in production plant 3350.

There are numerous scenarios for Multi Plant Planning, I hope this blog has established a baseline understanding of how Multi Plant Planning works.

If you have any queries please feel free to ask.

- SAP Managed Tags:

- MAN Material Requirements Planning,

- MAN Production Planning (PP)

14 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

learning content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Kanban with production orders: Scheduling of orders in Enterprise Resource Planning Q&A

- Portfolio Management – Enhanced Financial Planning integration in Enterprise Resource Planning Blogs by SAP

- Enterprise Portfolio and Project Management in SAP S/4HANA Cloud, Private Edition 2023 FPS1 in Enterprise Resource Planning Blogs by SAP

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- Five Key assessments for a Smooth ECC to S/4HANA Transformation in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 |