- SAP Community

- Products and Technology

- Technology

- Technology Blogs by Members

- Add Van Stock items into Service Ticket

Technology Blogs by Members

Explore a vibrant mix of technical expertise, industry insights, and tech buzz in member blogs covering SAP products, technology, and events. Get in the mix!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

omkar_uthale2

Participant

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-31-2017

3:44 PM

Requirement:

As per latest release, SAP has introduced functionality of adding Parts from Van Stock into Service Ticket. But this functionality was not available in previous releases and in S/4HANA Integration scenarios.

This blog covers, how we can develop the same functionality of fetching Van Stock products from S/4HANA and display in additional tab on Service Ticket. This will also cover; how do we add fetched Van Stock products to Service and Repair Tab. Additionally it provides flexibility of searching Van Stock products with Material Number and an employee for whom Van Stock need to be searched. This covers the requirement on which the solution is been built.

Solution:

To fulfill this requirement, there will be 3 systems involved S4 HANA, HCI and C4C. Following developments will follow in respective systems.

S4/HANA:

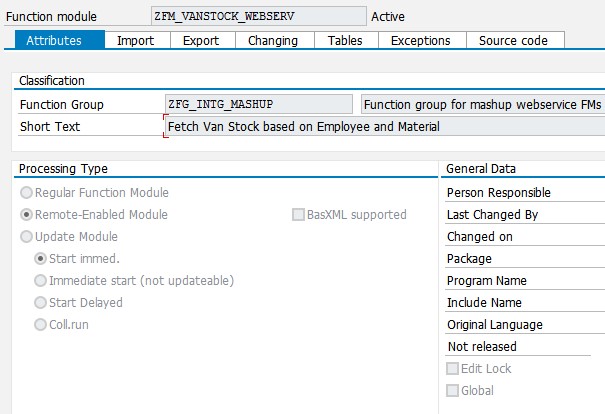

First we need a Web Service created based on a custom Function Module which allows us to search Van Stock with given search criteria. Below is screenshots for FM, you can build FM as per your requirement as well.

This is the output format by which it will return output.

FM source code is as below,

DATA: lv_storage_loc TYPE string,

lv_where_cls TYPE string,

lv_material_no TYPE string,

lv_spchar TYPE char1 VALUE '*',

lv_emp_id TYPE cod_service_emp,

lv_emp_name TYPE char80,

lv_fname TYPE char40,

lv_lname TYPE char40,

lv_plant TYPE string,

ls_out TYPE zsw_van_stck_rtrn.

DATA: BEGIN OF ls_output,

lv_matnr TYPE matnr,

lv_stloc TYPE lgort_d,

lv_descr TYPE maktx,

lv_qty TYPE labst,

END OF ls_output,

lt_output LIKE TABLE OF ls_output.

* Generate Data record for this FM

fbgenmac 'ZFM_VANSTOCK_WEBSERV'.

IF iv_emp_id IS NOT INITIAL.

* Get employee name

SELECT SINGLE vorna, nachn FROM pa0002 INTO (@lv_fname,@lv_lname) WHERE pernr = @iv_emp_id.

IF sy-subrc = 0.

* Get Storage location assigned to employee

SELECT SINGLE storage_loc, plant FROM cod_plant_srv INTO (@lv_storage_loc,@lv_plant) WHERE service_tech = @iv_emp_id.

* Start building where clause based on input

IF lv_storage_loc IS NOT INITIAL.

CONCATENATE '''' lv_storage_loc '''' INTO lv_storage_loc.

CONCATENATE 'a~LGORT' 'EQ' lv_storage_loc INTO lv_where_cls SEPARATED BY space.

* Add condition for material based on pattern if provided

IF iv_material_no IS NOT INITIAL.

IF iv_material_no CA lv_spchar.

REPLACE lv_spchar INTO iv_material_no WITH '%'.

CONCATENATE '''' iv_material_no '''' INTO lv_material_no.

CONCATENATE lv_where_cls 'AND' 'a~MATNR' 'LIKE' lv_material_no INTO lv_where_cls SEPARATED BY space.

ELSE.

CONCATENATE '''' iv_material_no '''' INTO lv_material_no.

CONCATENATE lv_where_cls 'AND' 'a~MATNR' 'EQ' lv_material_no INTO lv_where_cls SEPARATED BY space.

ENDIF.

ELSE.

CONCATENATE lv_where_cls 'AND' 'a~MATNR' 'LIKE' '''%''' INTO lv_where_cls SEPARATED BY space.

ENDIF.

* Finish where clause and fire query to fetch data

IF lv_where_cls IS NOT INITIAL.

CONCATENATE '''' lv_plant '''' INTO lv_plant.

CONCATENATE lv_where_cls 'AND' 'a~WERKS' 'EQ' lv_plant 'AND' 'b~SPRAS' 'EQ' '''E''' INTO lv_where_cls SEPARATED BY space.

SELECT a~matnr, a~lgort, b~maktx, a~labst FROM mard AS a INNER JOIN makt AS b ON a~matnr = b~matnr WHERE (lv_where_cls) ORDER BY a~matnr

INTO TABLE @lt_output.

ENDIF.

* Prepare output

CONDENSE lv_fname.

CONDENSE lv_lname.

IF sy-subrc = 0.

LOOP AT lt_output INTO ls_output.

ls_out-ev_material_no = ls_output-lv_matnr.

CONCATENATE lv_fname lv_lname INTO ls_out-ev_empl_name SEPARATED BY space.

ls_out-ev_description = ls_output-lv_descr.

ls_out-ev_stock = ls_output-lv_qty.

APPEND ls_out TO et_results.

ENDLOOP.

ELSE.

ls_out-ev_material_no = iv_material_no.

CONCATENATE lv_fname lv_lname INTO ls_out-ev_empl_name SEPARATED BY space.

ls_out-ev_description = TEXT-001.

APPEND ls_out TO et_results.

ENDIF.

ELSE.

CONDENSE lv_fname.

CONDENSE lv_lname.

CONCATENATE lv_fname lv_lname INTO ls_out-ev_empl_name SEPARATED BY space.

ls_out-ev_description = TEXT-002.

APPEND ls_out TO et_results.

ENDIF.

ELSE.

ls_out-ev_empl_name = TEXT-003.

APPEND ls_out TO et_results.

ENDIF.

ELSE.

ls_out-ev_empl_name = TEXT-004.

APPEND ls_out TO et_results.

ENDIF.After FM has been implemented, create a Web Service based on this FM as below:

After Web Service is created and it is exposed via SOAMANAGER configurations, download it’s WSDL. This WSDL will be used at 2 places, one in Cloud Application Studio to create External Web Service Integration(.wsid) and in HCI to create artifact. This artifact will be a mapping between C4C and S/4 system for communication.

HCI:

Below is artifact created in HCI:

Once this artifact is created and mapping has been done in HCI, this will end all prerequisites for Cloud Studio Developments.

Cloud Studio Developments:

In Cloud Studio first thing we need to do is extend standard Service Request object with 2 fields, 1 action and 1 node with 0: n cardinality. This will be required to hold the data temporarily. Particularly in this node extension, as we are not storing any Van Stock data in C4C, we need all the fields in node to be Transient. Please see below screenshot.

After this extension is created and activated, first we will create an empty implementation of action FetchVanStock.

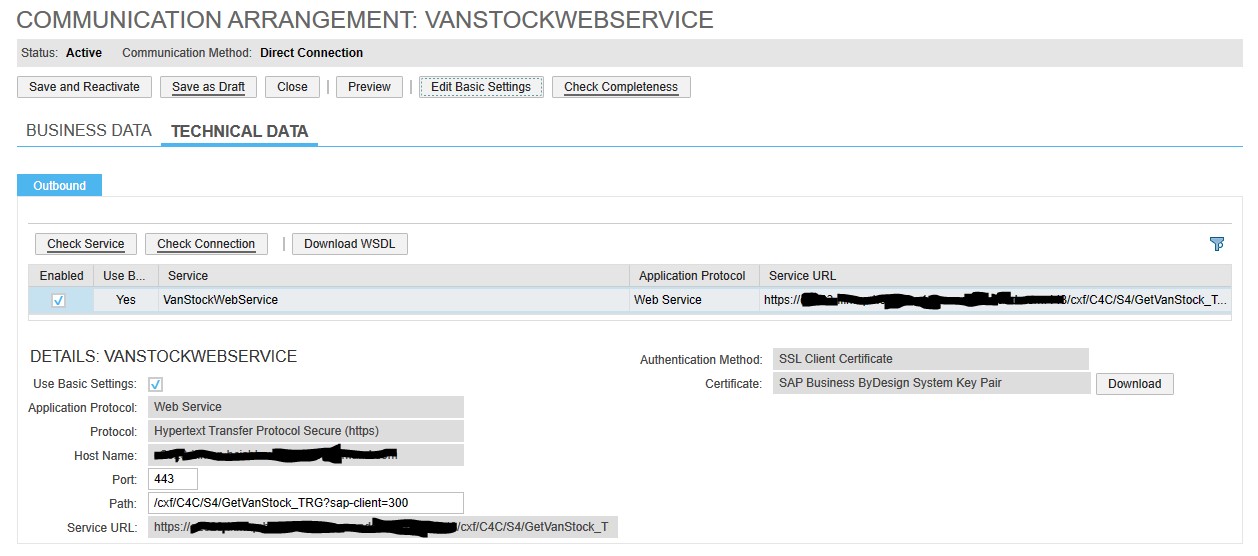

After this, we will create External Service Integration based on WSDL we have downloaded from S4 system. Then a communication scenario and communication arrangement will be created for this Web Service Integration. They will be as per below screenshot,

Communication Scenario:

Communication Arrangement:

Here only part that one must remember is path and Host Name should be taken from HCI instead of keeping it as original.

After this is done we will move on to implementing FetchVanStock action of our extension.

import ABSL;

import AP.Common.GDT;

import AP.CRM.Global;

import CommunicationServicesManagement.Global;

import AP.PC.IdentityManagement.Global;

import AP.FO.BusinessPartner.Global;

import AP.FO.ProductDataMaintenance.Global;

var requestVanStock: Library::VanStockWebService.ZfmVanstockWebserv.Request;

var responseVanStock: Library::VanStockWebService.ZfmVanstockWebserv.Response;

/*Below code is written to get Employee ID which need to be passed to Web Service.

1. See if User has selected Employee ID via F4 help provided on emplID field on screen

If yes then get it's External ID to pass to Web Service

2. If Employee ID is not selected then first we need to set a default id to this field

Default id is to be set as

a. Service Technician for current opened ticket

b. If Service Technician is not set in ticket then get current logged in user

After this employee is determined get thier External ID and set it in Web Service

import parameter */

if(!this.emplID.IsInitial()){

var empQuery = Employee.Identification.QueryByEmployeeAttributes;

var selParam = empQuery.CreateSelectionParams();

selParam.Add(empQuery.EmployeeID.content,"I","EQ",this.emplID.RemoveLeadingZeros().content);

var empResult = empQuery.Execute(selParam);

if(empResult.Count() > 0){

var empInst = empResult.GetFirst();

var objectQuery = ObjectIdentifierMapping.QueryByElements;

var selectParam = objectQuery.CreateSelectionParams();

selectParam.Add(objectQuery.LocalObjectNodeReference.UUID.content,"I","EQ",empInst.ToParent.UUID.content);

var objQueryRes = objectQuery.Execute(selectParam);

if(objQueryRes.Count() > 0){

var objectIDMapp = objQueryRes.GetFirst();

if(!objectIDMapp.RemoteObjectID.IsInitial()){

requestVanStock.IvEmpId = objectIDMapp.RemoteObjectID.content;

}

}

}

}

else{

var serviceTechnPartyCol = this.Party.Where(n=>n.RoleCode == "43");

if(serviceTechnPartyCol.Count() > 0){

var servTechnInst = serviceTechnPartyCol.GetFirst();

if(servTechnInst.Party.BusinessPartner.IsSet()){

var objectIdMappCol = servTechnInst.Party.BusinessPartner.ObjectIdentifierMapping;

if(objectIdMappCol.Count() > 0){

var objectIDMapp = objectIdMappCol.GetFirst();

if(!objectIDMapp.RemoteObjectID.IsInitial()){

requestVanStock.IvEmpId = objectIDMapp.RemoteObjectID.content;

this.emplID.content = servTechnInst.Party.Employee.IdentificationEmployeeID.EmployeeID.RemoveLeadingZeros().content;

}

}

}

}

else{

var identityUUID = Context.GetCurrentIdentityUUID();

var identity = Identity.Retrieve(identityUUID);

if(identity.IsSet()){

var partnerInst = BusinessPartner.Retrieve(identity.BusinessPartnerUUID);

if(partnerInst.IsSet()){

var objectIdMappCol = partnerInst.ObjectIdentifierMapping;

if(objectIdMappCol.Count() > 0){

var objectIDMapp = objectIdMappCol.GetFirst();

if(!objectIDMapp.RemoteObjectID.IsInitial()){

requestVanStock.IvEmpId = objectIDMapp.RemoteObjectID.content;

this.emplID.content = partnerInst.InternalID.RemoveLeadingZeros();

}

}

}

}

}

}

/*This below code is written to provide user a flexible search using wild card parameter(*)

This will ensure that right pattern is passed to Web Service*/

if(!this.materialNumb.IsInitial()){

var material = this.materialNumb.Replace("*","%");

var pos = material.Find("%");

var nextPos = material.FindLast("%");

if(pos != nextPos){

if(pos == 0 || nextPos == (this.materialNumb.Length() - 1)){

var subString1 = material.Substring(0,pos+1);

var subString2 = subString1.Replace("%","*");

var substring3 = material.Substring(pos+1,this.materialNumb.Length()-pos-1);

requestVanStock.IvMaterialNo = subString2.Concatenate(substring3);

}

else{

requestVanStock.IvMaterialNo = "%".Concatenate(material).Concatenate("*");

}

}

else{

if(pos == 0 || pos == (this.materialNumb.Length() - 1)){

requestVanStock.IvMaterialNo = this.materialNumb;

}

else{

requestVanStock.IvMaterialNo = "%".Concatenate(material).Concatenate("*");

}

}

}

else{

requestVanStock.IvMaterialNo = "*";

}

/*Call Web Service*/

responseVanStock = Library::VanStockWebService.ZfmVanstockWebserv(requestVanStock," ","VanStockWebService");

/*Once we receive results, either products or no result found, we will add them in our Node

Web Service has made sure that it will always have a result.

First we will delete current Van Stock node entries and then loop on received results

to create new rows inside our node extension*/

if(!responseVanStock.EtResults.IsInitial()){

var items = responseVanStock.EtResults.item;

if(this.VanStock.Count() > 0){

this.VanStock.Delete();

}

foreach(var item in items){

if(!item.EvStock.IsInitial()){

var vanStockNode: elementsof ServiceRequest.VanStock;

vanStockNode.MaterialNumber.content = item.EvMaterialNo;

vanStockNode.MatDescription = item.EvDescription;

vanStockNode.Stock.content = item.EvStock;

if(item.EvStockUnit.IsInitial() && !item.EvMaterialNo.IsInitial()){

var material = Material.Retrieve(vanStockNode.MaterialNumber);

if(material.IsSet() && material.ValuationQuantityUnit.IsSet()){

vanStockNode.Stock.unitCode = material.ValuationQuantityUnit.MeasureUnitCode;

}

else{

vanStockNode.Stock.unitCode = "EA";

}

}

vanStockNode.EmpName = item.EvEmplName;

this.VanStock.Create(vanStockNode);

}

}

}After this action is implemented, we will create and Embedded Component to display Van Stock. In Embedded Component, we will add model as per below explanation.

First bind root to ServiceRequest object and create InPort. Add newly created fields emplID and materialNum in model.

Next create a Data List by binding it to Item Node of Service Request.

Also add an Item modification structure for this Data List using given fields. This Data List will be a hidden Data List and will not be shown on screen.

Now go to Designer tab and start creating UI.

This will the UI that we will be creating. Mapping will be done as Service Employee is mapped to emplID field that we newly added. Material will be mapped to materialNum field.

After this we will add Advanced List Pane with toolbar as shown in above field. Before we do any further coding, we will map Data List created by this Pane to our new Node VanStock

Now our UI is built; we will start implementing various aspects of this Embedded Component.

First we will implement, Initialize event,

Whereas BOAction, which is called in second step, will be FetchVanStock.

This Event is called inside InPort that we have created as below,

After this create two more events as SubmitSearch and ResetSearch. They will be linked with toolbar buttons Go and Reset respectively.

SubmitSearch:

ResetSearch:

If implemented till this point, will give satisfactory result of viewing Van Stock from any Employee’s Van or searching for specific material in the same.

Now we will develop functionality to add selected material displayed on screen (from Van Stock) into Items (Service and Repair Tab). This was a little tricky part. Remember we have added Item Data List and List Modification structure in our Data Model. That plays a crucial role over here.

First we will do some tweaks in List to and Pane so that it behaves as per our needs.

First set List inside Advanced List Pane as Single Select.

Next make our Embedded Component Non-Work protect relevant so that whenever we use this tab in non-edit mode, it will not turn Service Request to edit mode.

Next we will change Service Employee to Object Value Selector using standard value help.

Next Go to Data Model and select VanStock Data List and in properties add below events,

The event is written to fill List Modification Structure with selected Product on screen.

Please note here that Material Number returned by Web Service has exact same id as that of C4C product due to all products already been replicated from S/4 to C4C.

Now back to our Add to Items button, this button will trigger an event which will call List Modification structure pop-up.

Next create a List Modification Form from List Modification structure we have created as below

After this is all done we need to add this Embedded Component to two TI Screens COD_SR_TI.TI.xuicomponent and COD_SEOD_Agent_Workspace_TI.TI.xuicomponent. Why two TI screens? This is because for Service Ticket there are two different screens for Desktop and Mobile devices. First TI screen mentioned above is for mobile devices and tablets whereas second screen is for desktop.

Once this is done, we are ready for the testing.

How it looks and Work:

In non-edit mode:

First time it will fetch all the materials in Van Stock of Service Technician. If Service Technician is not determined, then it will try with current logged in user.

In edit mode, it will let user edit Service Employee and Material pattern to search for specific Product.

To add one of the product from Van Stock, user have to select any row then press Add To Items button.

Here user can enter required quantity and when he presses Add button, it will get added to Service and Repair Tab.

This ends the blog content. Please let me know how it has turned up as it is my first attempt at blog.

Regards,

Omkar Uthale

5 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"automatische backups"

1 -

"regelmäßige sicherung"

1 -

"TypeScript" "Development" "FeedBack"

1 -

505 Technology Updates 53

1 -

ABAP

14 -

ABAP API

1 -

ABAP CDS Views

2 -

ABAP CDS Views - BW Extraction

1 -

ABAP CDS Views - CDC (Change Data Capture)

1 -

ABAP class

2 -

ABAP Cloud

2 -

ABAP Development

5 -

ABAP in Eclipse

1 -

ABAP Platform Trial

1 -

ABAP Programming

2 -

abap technical

1 -

absl

2 -

access data from SAP Datasphere directly from Snowflake

1 -

Access data from SAP datasphere to Qliksense

1 -

Accrual

1 -

action

1 -

adapter modules

1 -

Addon

1 -

Adobe Document Services

1 -

ADS

1 -

ADS Config

1 -

ADS with ABAP

1 -

ADS with Java

1 -

ADT

2 -

Advance Shipping and Receiving

1 -

Advanced Event Mesh

3 -

AEM

1 -

AI

7 -

AI Launchpad

1 -

AI Projects

1 -

AIML

9 -

Alert in Sap analytical cloud

1 -

Amazon S3

1 -

Analytical Dataset

1 -

Analytical Model

1 -

Analytics

1 -

Analyze Workload Data

1 -

annotations

1 -

API

1 -

API and Integration

3 -

API Call

2 -

Application Architecture

1 -

Application Development

5 -

Application Development for SAP HANA Cloud

3 -

Applications and Business Processes (AP)

1 -

Artificial Intelligence

1 -

Artificial Intelligence (AI)

5 -

Artificial Intelligence (AI) 1 Business Trends 363 Business Trends 8 Digital Transformation with Cloud ERP (DT) 1 Event Information 462 Event Information 15 Expert Insights 114 Expert Insights 76 Life at SAP 418 Life at SAP 1 Product Updates 4

1 -

Artificial Intelligence (AI) blockchain Data & Analytics

1 -

Artificial Intelligence (AI) blockchain Data & Analytics Intelligent Enterprise

1 -

Artificial Intelligence (AI) blockchain Data & Analytics Intelligent Enterprise Oil Gas IoT Exploration Production

1 -

Artificial Intelligence (AI) blockchain Data & Analytics Intelligent Enterprise sustainability responsibility esg social compliance cybersecurity risk

1 -

ASE

1 -

ASR

2 -

ASUG

1 -

Attachments

1 -

Authorisations

1 -

Automating Processes

1 -

Automation

2 -

aws

2 -

Azure

1 -

Azure AI Studio

1 -

B2B Integration

1 -

Backorder Processing

1 -

Backup

1 -

Backup and Recovery

1 -

Backup schedule

1 -

BADI_MATERIAL_CHECK error message

1 -

Bank

1 -

BAS

1 -

basis

2 -

Basis Monitoring & Tcodes with Key notes

2 -

Batch Management

1 -

BDC

1 -

Best Practice

1 -

bitcoin

1 -

Blockchain

3 -

bodl

1 -

BOP in aATP

1 -

BOP Segments

1 -

BOP Strategies

1 -

BOP Variant

1 -

BPC

1 -

BPC LIVE

1 -

BTP

12 -

BTP Destination

2 -

Business AI

1 -

Business and IT Integration

1 -

Business application stu

1 -

Business Application Studio

1 -

Business Architecture

1 -

Business Communication Services

1 -

Business Continuity

1 -

Business Data Fabric

3 -

Business Partner

12 -

Business Partner Master Data

10 -

Business Technology Platform

2 -

Business Trends

4 -

CA

1 -

calculation view

1 -

CAP

3 -

Capgemini

1 -

CAPM

1 -

Catalyst for Efficiency: Revolutionizing SAP Integration Suite with Artificial Intelligence (AI) and

1 -

CCMS

2 -

CDQ

12 -

CDS

2 -

Cental Finance

1 -

Certificates

1 -

CFL

1 -

Change Management

1 -

chatbot

1 -

chatgpt

3 -

CL_SALV_TABLE

2 -

Class Runner

1 -

Classrunner

1 -

Cloud ALM Monitoring

1 -

Cloud ALM Operations

1 -

cloud connector

1 -

Cloud Extensibility

1 -

Cloud Foundry

4 -

Cloud Integration

6 -

Cloud Platform Integration

2 -

cloudalm

1 -

communication

1 -

Compensation Information Management

1 -

Compensation Management

1 -

Compliance

1 -

Compound Employee API

1 -

Configuration

1 -

Connectors

1 -

Consolidation Extension for SAP Analytics Cloud

2 -

Control Indicators.

1 -

Controller-Service-Repository pattern

1 -

Conversion

1 -

Cosine similarity

1 -

cryptocurrency

1 -

CSI

1 -

ctms

1 -

Custom chatbot

3 -

Custom Destination Service

1 -

custom fields

1 -

Customer Experience

1 -

Customer Journey

1 -

Customizing

1 -

cyber security

3 -

cybersecurity

1 -

Data

1 -

Data & Analytics

1 -

Data Aging

1 -

Data Analytics

2 -

Data and Analytics (DA)

1 -

Data Archiving

1 -

Data Back-up

1 -

Data Flow

1 -

Data Governance

5 -

Data Integration

2 -

Data Quality

12 -

Data Quality Management

12 -

Data Synchronization

1 -

data transfer

1 -

Data Unleashed

1 -

Data Value

8 -

database tables

1 -

Datasphere

3 -

datenbanksicherung

1 -

dba cockpit

1 -

dbacockpit

1 -

Debugging

2 -

Delimiting Pay Components

1 -

Delta Integrations

1 -

Destination

3 -

Destination Service

1 -

Developer extensibility

1 -

Developing with SAP Integration Suite

1 -

Devops

1 -

digital transformation

1 -

Documentation

1 -

Dot Product

1 -

DQM

1 -

dump database

1 -

dump transaction

1 -

e-Invoice

1 -

E4H Conversion

1 -

Eclipse ADT ABAP Development Tools

2 -

edoc

1 -

edocument

1 -

ELA

1 -

Embedded Consolidation

1 -

Embedding

1 -

Embeddings

1 -

Employee Central

1 -

Employee Central Payroll

1 -

Employee Central Time Off

1 -

Employee Information

1 -

Employee Rehires

1 -

Enable Now

1 -

Enable now manager

1 -

endpoint

1 -

Enhancement Request

1 -

Enterprise Architecture

1 -

ETL Business Analytics with SAP Signavio

1 -

Euclidean distance

1 -

Event Dates

1 -

Event Driven Architecture

1 -

Event Mesh

2 -

Event Reason

1 -

EventBasedIntegration

1 -

EWM

1 -

EWM Outbound configuration

1 -

EWM-TM-Integration

1 -

Existing Event Changes

1 -

Expand

1 -

Expert

2 -

Expert Insights

2 -

Exploits

1 -

Fiori

14 -

Fiori Elements

2 -

Fiori SAPUI5

12 -

Flask

1 -

Full Stack

8 -

Funds Management

1 -

General

1 -

General Splitter

1 -

Generative AI

1 -

Getting Started

1 -

GitHub

8 -

Grants Management

1 -

GraphQL

1 -

groovy

1 -

GTP

1 -

HANA

6 -

HANA Cloud

2 -

Hana Cloud Database Integration

2 -

HANA DB

2 -

HANA XS Advanced

1 -

Historical Events

1 -

home labs

1 -

HowTo

1 -

HR Data Management

1 -

html5

8 -

HTML5 Application

1 -

Identity cards validation

1 -

idm

1 -

Implementation

1 -

input parameter

1 -

instant payments

1 -

Integration

3 -

Integration Advisor

1 -

Integration Architecture

1 -

Integration Center

1 -

Integration Suite

1 -

intelligent enterprise

1 -

iot

1 -

Java

1 -

job

1 -

Job Information Changes

1 -

Job-Related Events

1 -

Job_Event_Information

1 -

joule

4 -

Journal Entries

1 -

Just Ask

1 -

Kerberos for ABAP

8 -

Kerberos for JAVA

8 -

KNN

1 -

Launch Wizard

1 -

Learning Content

2 -

Life at SAP

5 -

lightning

1 -

Linear Regression SAP HANA Cloud

1 -

Loading Indicator

1 -

local tax regulations

1 -

LP

1 -

Machine Learning

2 -

Marketing

1 -

Master Data

3 -

Master Data Management

14 -

Maxdb

2 -

MDG

1 -

MDGM

1 -

MDM

1 -

Message box.

1 -

Messages on RF Device

1 -

Microservices Architecture

1 -

Microsoft Universal Print

1 -

Middleware Solutions

1 -

Migration

5 -

ML Model Development

1 -

Modeling in SAP HANA Cloud

8 -

Monitoring

3 -

MTA

1 -

Multi-Record Scenarios

1 -

Multiple Event Triggers

1 -

Myself Transformation

1 -

Neo

1 -

New Event Creation

1 -

New Feature

1 -

Newcomer

1 -

NodeJS

2 -

ODATA

2 -

OData APIs

1 -

odatav2

1 -

ODATAV4

1 -

ODBC

1 -

ODBC Connection

1 -

Onpremise

1 -

open source

2 -

OpenAI API

1 -

Oracle

1 -

PaPM

1 -

PaPM Dynamic Data Copy through Writer function

1 -

PaPM Remote Call

1 -

PAS-C01

1 -

Pay Component Management

1 -

PGP

1 -

Pickle

1 -

PLANNING ARCHITECTURE

1 -

Popup in Sap analytical cloud

1 -

PostgrSQL

1 -

POSTMAN

1 -

Process Automation

2 -

Product Updates

4 -

PSM

1 -

Public Cloud

1 -

Python

4 -

Qlik

1 -

Qualtrics

1 -

RAP

3 -

RAP BO

2 -

Record Deletion

1 -

Recovery

1 -

recurring payments

1 -

redeply

1 -

Release

1 -

Remote Consumption Model

1 -

Replication Flows

1 -

research

1 -

Resilience

1 -

REST

1 -

REST API

2 -

Retagging Required

1 -

Risk

1 -

Rolling Kernel Switch

1 -

route

1 -

rules

1 -

S4 HANA

1 -

S4 HANA Cloud

1 -

S4 HANA On-Premise

1 -

S4HANA

3 -

S4HANA_OP_2023

2 -

SAC

10 -

SAC PLANNING

9 -

SAP

4 -

SAP ABAP

1 -

SAP Advanced Event Mesh

1 -

SAP AI Core

8 -

SAP AI Launchpad

8 -

SAP Analytic Cloud Compass

1 -

Sap Analytical Cloud

1 -

SAP Analytics Cloud

4 -

SAP Analytics Cloud for Consolidation

3 -

SAP Analytics Cloud Story

1 -

SAP analytics clouds

1 -

SAP BAS

1 -

SAP Basis

6 -

SAP BODS

1 -

SAP BODS certification.

1 -

SAP BTP

21 -

SAP BTP Build Work Zone

2 -

SAP BTP Cloud Foundry

6 -

SAP BTP Costing

1 -

SAP BTP CTMS

1 -

SAP BTP Innovation

1 -

SAP BTP Migration Tool

1 -

SAP BTP SDK IOS

1 -

SAP Build

11 -

SAP Build App

1 -

SAP Build apps

1 -

SAP Build CodeJam

1 -

SAP Build Process Automation

3 -

SAP Build work zone

10 -

SAP Business Objects Platform

1 -

SAP Business Technology

2 -

SAP Business Technology Platform (XP)

1 -

sap bw

1 -

SAP CAP

2 -

SAP CDC

1 -

SAP CDP

1 -

SAP CDS VIEW

1 -

SAP Certification

1 -

SAP Cloud ALM

4 -

SAP Cloud Application Programming Model

1 -

SAP Cloud Integration for Data Services

1 -

SAP cloud platform

8 -

SAP Companion

1 -

SAP CPI

3 -

SAP CPI (Cloud Platform Integration)

2 -

SAP CPI Discover tab

1 -

sap credential store

1 -

SAP Customer Data Cloud

1 -

SAP Customer Data Platform

1 -

SAP Data Intelligence

1 -

SAP Data Migration in Retail Industry

1 -

SAP Data Services

1 -

SAP DATABASE

1 -

SAP Dataspher to Non SAP BI tools

1 -

SAP Datasphere

9 -

SAP DRC

1 -

SAP EWM

1 -

SAP Fiori

3 -

SAP Fiori App Embedding

1 -

Sap Fiori Extension Project Using BAS

1 -

SAP GRC

1 -

SAP HANA

1 -

SAP HCM (Human Capital Management)

1 -

SAP HR Solutions

1 -

SAP IDM

1 -

SAP Integration Suite

9 -

SAP Integrations

4 -

SAP iRPA

2 -

SAP LAGGING AND SLOW

1 -

SAP Learning Class

1 -

SAP Learning Hub

1 -

SAP Master Data

1 -

SAP Odata

2 -

SAP on Azure

1 -

SAP PartnerEdge

1 -

sap partners

1 -

SAP Password Reset

1 -

SAP PO Migration

1 -

SAP Prepackaged Content

1 -

SAP Process Automation

2 -

SAP Process Integration

2 -

SAP Process Orchestration

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud

1 -

SAP S4HANA Cloud for Finance

1 -

SAP S4HANA Cloud private edition

1 -

SAP Sandbox

1 -

SAP STMS

1 -

SAP successfactors

3 -

SAP SuccessFactors HXM Core

1 -

SAP Time

1 -

SAP TM

2 -

SAP Trading Partner Management

1 -

SAP UI5

1 -

SAP Upgrade

1 -

SAP Utilities

1 -

SAP-GUI

8 -

SAP_COM_0276

1 -

SAPBTP

1 -

SAPCPI

1 -

SAPEWM

1 -

sapmentors

1 -

saponaws

2 -

SAPS4HANA

1 -

SAPUI5

5 -

schedule

1 -

Script Operator

1 -

Secure Login Client Setup

8 -

security

9 -

Selenium Testing

1 -

Self Transformation

1 -

Self-Transformation

1 -

SEN

1 -

SEN Manager

1 -

service

1 -

SET_CELL_TYPE

1 -

SET_CELL_TYPE_COLUMN

1 -

SFTP scenario

2 -

Simplex

1 -

Single Sign On

8 -

Singlesource

1 -

SKLearn

1 -

Slow loading

1 -

soap

1 -

Software Development

1 -

SOLMAN

1 -

solman 7.2

2 -

Solution Manager

3 -

sp_dumpdb

1 -

sp_dumptrans

1 -

SQL

1 -

sql script

1 -

SSL

8 -

SSO

8 -

Substring function

1 -

SuccessFactors

1 -

SuccessFactors Platform

1 -

SuccessFactors Time Tracking

1 -

Sybase

1 -

system copy method

1 -

System owner

1 -

Table splitting

1 -

Tax Integration

1 -

Technical article

1 -

Technical articles

1 -

Technology Updates

14 -

Technology Updates

1 -

Technology_Updates

1 -

terraform

1 -

Threats

2 -

Time Collectors

1 -

Time Off

2 -

Time Sheet

1 -

Time Sheet SAP SuccessFactors Time Tracking

1 -

Tips and tricks

2 -

toggle button

1 -

Tools

1 -

Trainings & Certifications

1 -

Transformation Flow

1 -

Transport in SAP BODS

1 -

Transport Management

1 -

TypeScript

2 -

ui designer

1 -

unbind

1 -

Unified Customer Profile

1 -

UPB

1 -

Use of Parameters for Data Copy in PaPM

1 -

User Unlock

1 -

VA02

1 -

Validations

1 -

Vector Database

2 -

Vector Engine

1 -

Visual Studio Code

1 -

VSCode

1 -

Vulnerabilities

1 -

Web SDK

1 -

work zone

1 -

workload

1 -

xsa

1 -

XSA Refresh

1

- « Previous

- Next »

Related Content

- What’s new in Mobile development kit client 24.4 in Technology Blogs by SAP

- Scheduled Report shows successful status; but Mail server never Receives... Where's the problem? in Technology Q&A

- NCO 2.0 and UNICODE compatibility in Technology Q&A

- Handle the behavior of extension field by toggle button using SDK UI designer. in Technology Blogs by Members

- Developing & Deploying the UI5 App to Cloud Foundry and Accessing from App-router End-to-End Steps in Technology Blogs by Members

Top kudoed authors

| User | Count |

|---|---|

| 8 | |

| 5 | |

| 5 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 3 |