- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- SAP Tech Tips: Advanced Available-to-Promise (aATP...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

oegxp001

Explorer

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-12-2017

7:46 PM

The S/4HANA 1610 release introduces advanced available-to-promise (aATP) with new functionality to better execute order fulfillment and improve supply chain processes. This blog explains the detailed configuration and master data settings necessary to implement the aATP process.

Before we explain the actions to set up the systems, we need to first address the larger questions:

Let’s Begin with a Story…

Our company manufactures and sells toys based on licensing agreements with major movie studios, a business with some hits along with a fair share of misses. This year we developed a toy elephant of the lead character, Newton, in the animated movie . Immediately following the late summer release, our sales went vertical. The movie turned into the megahit of the year, double the combined gross of the next three films, and global demand for Newton was raging into the holiday season.

Quickly ramping up new contract manufacturer capacity, we still could not keep pace with the demand, raising the proverbial “good problem to have” of more sales than we could satisfy. What could we do now? How could we best prioritize our Newton stock to maximize our sales and profits? What solution could organize the chaos before Newton became old news?

If we had the standard ATP, we could see sales and inventory for each plant and distribution center in the network. With our global business, that is not enough. Global ATP perhaps? An improvement for sure, which provides us with visibility across the network and allows us to allocate inventory via production and stock transfers that can be pegged to sales orders. But is that sufficient for this situation? Or do we need something better?

aATP to the Rescue

With aATP, the something better is here. Now we can achieve improved performance with the in-memory S/4HANA platform, customize and execute our process with new Fiori apps and, most importantly, assign inventory to our prioritized customers with the new “Win/Gain/Redistribute/Fill/Lose” strategies. These powerful strategies are built into the system, running with the improved backorder processing (BOP) to ensure our key accounts are delivered on time and in full, even with a last-minute, short lead-time order.

Ideally, we strive to fill all orders, but realistically that is not always feasible. This may mean we have to take previously confirmed stock from a lower-priority customer and reallocate to fill the new higher-priority order. Automation will drive the decisions more efficiently, identify and adjust to rapidly changing circumstances, and fill orders with optimal business savvy, based on our own unique variables.

Whether we are selling toys, high tech, automotive, consumer products, or any number of other types of business with rapidly changing dynamics, any product may have a shelf life equivalent to fresh fruit, with no time to spare. Whether they are major accounts, higher-margin businesses, strategic relationships, or less-critical channels, we can rapidly optimize our network and respond to changing circumstances to best suit our business requirements.

How to Implement the aATP Process

Now, let’s get busy using our system, as Newton will reach brick-and-mortar store shelves and e-commerce sites this week.

Our first task will be to Activate aATP functionality in our 1610 system. The IMG path is the first entry: SAP Customizing Implementation Guide > Activate Business Functions.

In this object, open the folder S/4H_ALWAYS_ON_FUNCTIONS and scroll to the bottom. You will see the entry S4H_AATP below and can confirm the activated status.

After activation, we proceed to sections of the initial configuration, which will appear similar, as these are aligned with the standard ATP process from earlier ECC versions.

We begin by defining the Requirements Classes and Types with their assignment to specific Item Categories and Schedule Line Categories. The documentation icons outlined in the screenshot provide detailed descriptions of each IMG object for reference. The standard system will deliver core values with flexibility to create new or update existing values as needed.

Following the IMG path: Sales and Distribution > Basic Functions > Availability Check and Transfer of Requirements > Transfer of Requirements > and the subfolders displayed next.

Checking Groups make up the next section, with the IMG path: Sales and Distribution > Basic Functions > Availability Check and Transfer of Requirements > Availability Check > Availability Check with ATP Logic or Against Planning, followed by another set of subfolders.

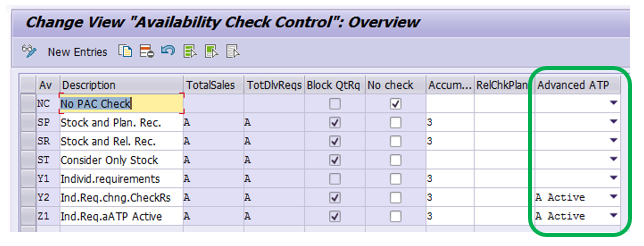

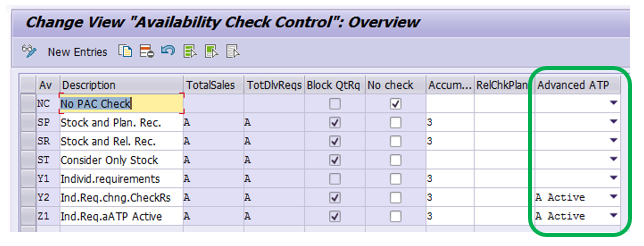

We find an important change to Activate aATP within the first task, Define Checking Groups. Note the far right column now lists two choices, Active and Blank. Set the indicator as appropriate for each Checking Group.

When this configuration is complete, Checking Groups are assigned to each material in Master Data.

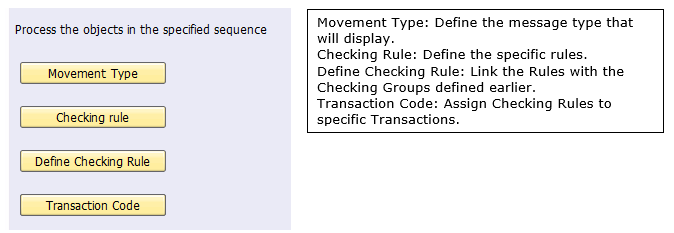

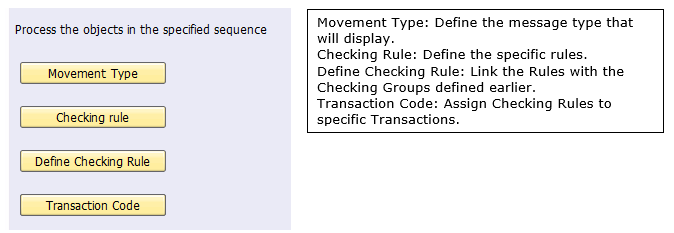

Checking Rules will be assigned to each Checking Group and this IMG object is available in several different folders. We will follow this path to access the Checking Rules:

Cross-Application Components > Advanced Available-to-Promise (ATP) > General Activities for Advanced Available-to-Promise (ATP) > Stock Movements > Set Up Dynamic Availability Check. Four different buttons are within this structure, where we again begin with standard values and make adjustments as needed.

After the Checking Rules are established, we proceed to Product Allocation setup. These values guide the system in deciding how inventory per material is confirmed for sales orders. The first step is to define the Allocation Procedure, followed by further definition details in the remaining folders. Once complete, these procedures are assigned to each material via master data.

Sales and Distribution > Basic Functions > Availability Check and Transfer of Requirements > Availability Check > Availability Check Against Product Allocation > followed by a group of subfolders.

We will complete each of the objects listed, beginning with Maintain Procedure:

The last task in this section is the Check Settings in Product Allocation item. This is a system check to identify any errors that will prevent proper functionality: red messages equal errors. You can click any line item to display the error and corrective actions.

Moving forward, we now open the new IMG path for aATP: Cross-Application Components > Advanced Available-to-Promise (ATP), where we see six folders, each containing further setup points. We can skip the Product Availability Check folder, as this has repeated settings that we completed earlier.

3. The folders Backorder Processing and Rules-Based Availability Check contain default settings that apply to most common scenarios, but can be revised if desired.

4. Optional BAdIs are available in the Business Add-Ins (BAdIs) for Advanced Available-to-Promise (ATP) folder.

The last IMG task requires updating the Logistics Information System (LIS) control for the Product Allocation Info Structure S140. IMG path:

With our IMG activities completed, we next change applicable Material Master records with two settings: Product Allocation Procedure on Basic Data 1 and Checking Group on Sales General/Plant or MRP 3.

Our remaining task is to implement three SAP Notes that will set up the HANA Rules Framework (HRF) and Business Rules Framework Plus (BRF+ necessary for BOP operations. Further details are included within each note.

Now that we completed the detailed configuration, activated aATP and Product Allocations, and revised our Master Data, we are ready to move forward with the transactional data to put the aATP process in motion.

Watch this space where we will soon share the next blog post: Advanced Available-to-Promise (aATP) in S/4HANA 1610 Execution.

If you have recommendations to improve the processes above, please leave us a comment or tweet us at @CenturylinkEnt.

References:

Sven Denecken aATP technical view: Compares benefits and explains the differences between Classic ATP, gATP executed within APO and the new aATP embedded into the S/4HANA 1610 release.

Sven Denecken aATP business view: Explains the business and functional improvements gained with aATP.

Rahul Agarwal aATP blog post: Documents the seven new Fiori apps, with good explanations of their capabilities.

Before we explain the actions to set up the systems, we need to first address the larger questions:

- What is the compelling reason my company should move to 1610 and purchase the aATP license?

- What do I gain from this investment?

Let’s Begin with a Story…

Our company manufactures and sells toys based on licensing agreements with major movie studios, a business with some hits along with a fair share of misses. This year we developed a toy elephant of the lead character, Newton, in the animated movie . Immediately following the late summer release, our sales went vertical. The movie turned into the megahit of the year, double the combined gross of the next three films, and global demand for Newton was raging into the holiday season.

Quickly ramping up new contract manufacturer capacity, we still could not keep pace with the demand, raising the proverbial “good problem to have” of more sales than we could satisfy. What could we do now? How could we best prioritize our Newton stock to maximize our sales and profits? What solution could organize the chaos before Newton became old news?

If we had the standard ATP, we could see sales and inventory for each plant and distribution center in the network. With our global business, that is not enough. Global ATP perhaps? An improvement for sure, which provides us with visibility across the network and allows us to allocate inventory via production and stock transfers that can be pegged to sales orders. But is that sufficient for this situation? Or do we need something better?

aATP to the Rescue

With aATP, the something better is here. Now we can achieve improved performance with the in-memory S/4HANA platform, customize and execute our process with new Fiori apps and, most importantly, assign inventory to our prioritized customers with the new “Win/Gain/Redistribute/Fill/Lose” strategies. These powerful strategies are built into the system, running with the improved backorder processing (BOP) to ensure our key accounts are delivered on time and in full, even with a last-minute, short lead-time order.

Ideally, we strive to fill all orders, but realistically that is not always feasible. This may mean we have to take previously confirmed stock from a lower-priority customer and reallocate to fill the new higher-priority order. Automation will drive the decisions more efficiently, identify and adjust to rapidly changing circumstances, and fill orders with optimal business savvy, based on our own unique variables.

Whether we are selling toys, high tech, automotive, consumer products, or any number of other types of business with rapidly changing dynamics, any product may have a shelf life equivalent to fresh fruit, with no time to spare. Whether they are major accounts, higher-margin businesses, strategic relationships, or less-critical channels, we can rapidly optimize our network and respond to changing circumstances to best suit our business requirements.

How to Implement the aATP Process

Now, let’s get busy using our system, as Newton will reach brick-and-mortar store shelves and e-commerce sites this week.

Our first task will be to Activate aATP functionality in our 1610 system. The IMG path is the first entry: SAP Customizing Implementation Guide > Activate Business Functions.

In this object, open the folder S/4H_ALWAYS_ON_FUNCTIONS and scroll to the bottom. You will see the entry S4H_AATP below and can confirm the activated status.

After activation, we proceed to sections of the initial configuration, which will appear similar, as these are aligned with the standard ATP process from earlier ECC versions.

We begin by defining the Requirements Classes and Types with their assignment to specific Item Categories and Schedule Line Categories. The documentation icons outlined in the screenshot provide detailed descriptions of each IMG object for reference. The standard system will deliver core values with flexibility to create new or update existing values as needed.

Following the IMG path: Sales and Distribution > Basic Functions > Availability Check and Transfer of Requirements > Transfer of Requirements > and the subfolders displayed next.

Checking Groups make up the next section, with the IMG path: Sales and Distribution > Basic Functions > Availability Check and Transfer of Requirements > Availability Check > Availability Check with ATP Logic or Against Planning, followed by another set of subfolders.

We find an important change to Activate aATP within the first task, Define Checking Groups. Note the far right column now lists two choices, Active and Blank. Set the indicator as appropriate for each Checking Group.

When this configuration is complete, Checking Groups are assigned to each material in Master Data.

Checking Rules will be assigned to each Checking Group and this IMG object is available in several different folders. We will follow this path to access the Checking Rules:

Cross-Application Components > Advanced Available-to-Promise (ATP) > General Activities for Advanced Available-to-Promise (ATP) > Stock Movements > Set Up Dynamic Availability Check. Four different buttons are within this structure, where we again begin with standard values and make adjustments as needed.

After the Checking Rules are established, we proceed to Product Allocation setup. These values guide the system in deciding how inventory per material is confirmed for sales orders. The first step is to define the Allocation Procedure, followed by further definition details in the remaining folders. Once complete, these procedures are assigned to each material via master data.

Sales and Distribution > Basic Functions > Availability Check and Transfer of Requirements > Availability Check > Availability Check Against Product Allocation > followed by a group of subfolders.

We will complete each of the objects listed, beginning with Maintain Procedure:

- Planning Version 000 is required and can be created with MC93 and Planning Type COMMIT

- Planning Hierarchy is also required and created with MC61

- For the object “Process Flow for Each Schedule Line Category,” there are three check boxes to activate for all Schedule Line Categories that will use aATP:

The last task in this section is the Check Settings in Product Allocation item. This is a system check to identify any errors that will prevent proper functionality: red messages equal errors. You can click any line item to display the error and corrective actions.

Moving forward, we now open the new IMG path for aATP: Cross-Application Components > Advanced Available-to-Promise (ATP), where we see six folders, each containing further setup points. We can skip the Product Availability Check folder, as this has repeated settings that we completed earlier.

- General Activities for aATP:

- This folder has four subfolders, two of which contain duplication updated earlier.

- Opening the new folders, for Production/Process Orders and Stock Transport Orders, we define the aATP settings to guide the system in these two areas.

- The Product Allocation folder contains the essential on/off switch to activate Allocations. We also have optional number ranges that we can create as needed. The Documentation icon also provides further details to validate all applicable settings.

3. The folders Backorder Processing and Rules-Based Availability Check contain default settings that apply to most common scenarios, but can be revised if desired.

4. Optional BAdIs are available in the Business Add-Ins (BAdIs) for Advanced Available-to-Promise (ATP) folder.

The last IMG task requires updating the Logistics Information System (LIS) control for the Product Allocation Info Structure S140. IMG path:

- Logistics > General > Logistics Information System (LIS) > Logistics Data Warehouse > Updating > Updating Control > Activate Update for the Sales and Distribution item

- Select S140 and display the details

- Set to Updating radio button to Synchronous Update

With our IMG activities completed, we next change applicable Material Master records with two settings: Product Allocation Procedure on Basic Data 1 and Checking Group on Sales General/Plant or MRP 3.

Our remaining task is to implement three SAP Notes that will set up the HANA Rules Framework (HRF) and Business Rules Framework Plus (BRF+ necessary for BOP operations. Further details are included within each note.

- 2400537: Backorder Processing in Available-to-Promise (ATP) in SAP S/4HANA

- 2345697: BRF+ analytical decision table check Call CL_FDT_XS=>GET_INSTANCE with RFC destination

- 2351188: BRF+ Analytical function generation - Derive default schema dynamically

Now that we completed the detailed configuration, activated aATP and Product Allocations, and revised our Master Data, we are ready to move forward with the transactional data to put the aATP process in motion.

Watch this space where we will soon share the next blog post: Advanced Available-to-Promise (aATP) in S/4HANA 1610 Execution.

If you have recommendations to improve the processes above, please leave us a comment or tweet us at @CenturylinkEnt.

References:

Sven Denecken aATP technical view: Compares benefits and explains the differences between Classic ATP, gATP executed within APO and the new aATP embedded into the S/4HANA 1610 release.

Sven Denecken aATP business view: Explains the business and functional improvements gained with aATP.

Rahul Agarwal aATP blog post: Documents the seven new Fiori apps, with good explanations of their capabilities.

- SAP Managed Tags:

- SAP S/4HANA,

- SCM APO Global ATP

9 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Explanation of the Delta Posting Logic in Advanced Foreign Currency Valuation in Enterprise Resource Planning Blogs by SAP

- Advance Return Management complete configuration(SAP ARM) in Enterprise Resource Planning Blogs by Members

- Intercompany Execution of Services (aka "Dual Order") in Enterprise Resource Planning Blogs by SAP

- SAP ERP Functionality for EDI Processing: UoMs Determination for Inbound Orders in Enterprise Resource Planning Blogs by Members

- Machines grouping in work centers for Textile Industry in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |