- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Subcontracting in Business ByDesign

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Employee

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

04-12-2017

3:13 PM

Many companies have sub-contracting established as a process in their business.

In Sub-contracting process, all or a part of the manufacturing process of a product is executed by an external party.

If you need to execute sub-contracting with the ByDesign, please follow the below mentioned steps. These steps ensures that the Logistics and material planning part of the business process is properly captured in the system.

The costing and invoicing part of the scenario are not covered here.

The invoicing and costing has to be triggered manually and is not connected to the Logistics process mentioned here.

As of now, please follow below steps to execute the sub-contracting scenario in SAP Business ByDesign.

The above steps will take care of the logistics part of your subcontracting process.

To pay the subcontractor you will have to create a purchase order with service item with your subcontractor as the supplier. You can create a supplier invoice against this purchase order and pay the subcontractor as per your agreement.

The above steps will help you execute the subcontracting business process in your ByD system. Please do reach out to me via the comments section for any more queries on the same.

Note : Please refer the Blog Subcontracting in SAP Business ByDesign – Part II to have a deeper look into how one could set up the system to better align the production process with the service purchasing process.

In Sub-contracting process, all or a part of the manufacturing process of a product is executed by an external party.

If you need to execute sub-contracting with the ByDesign, please follow the below mentioned steps. These steps ensures that the Logistics and material planning part of the business process is properly captured in the system.

The costing and invoicing part of the scenario are not covered here.

The invoicing and costing has to be triggered manually and is not connected to the Logistics process mentioned here.

As of now, please follow below steps to execute the sub-contracting scenario in SAP Business ByDesign.

Assumptions:

- Finished Good is produced at your subcontractor.

- Raw materials are supplied by the company.

Master Data Settings:

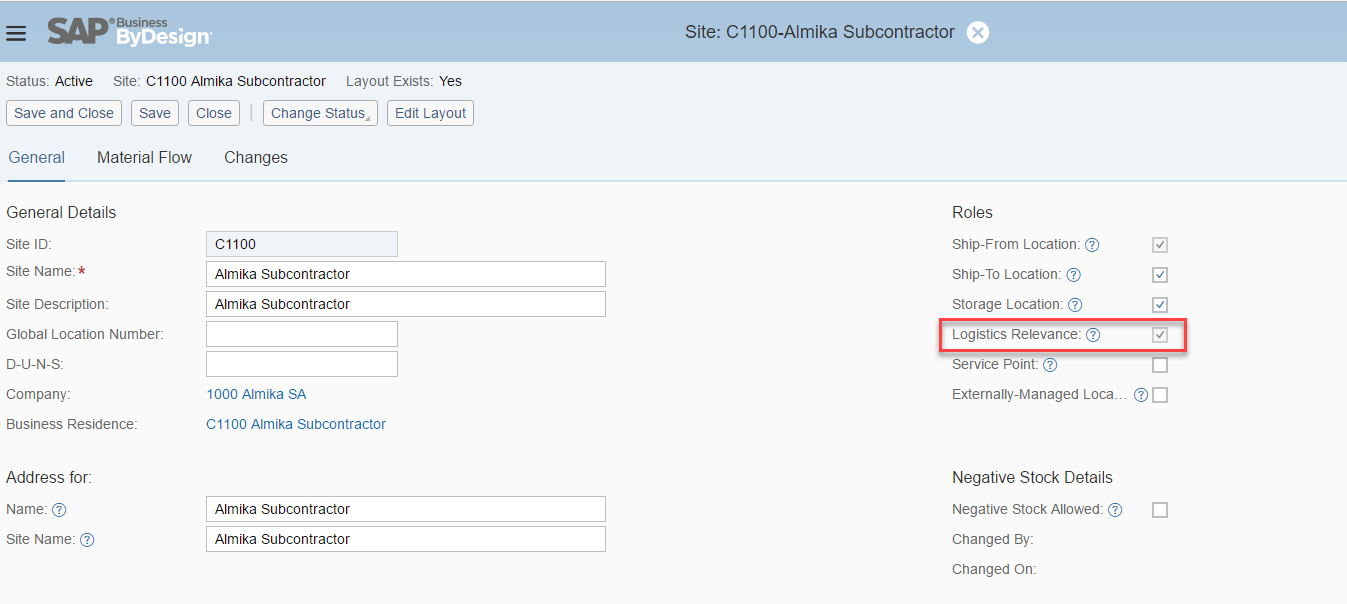

- Create a site in your system which will denote your subcontractor. I have assigned created a new org unit with ID C1100 as you can see in the screen shot below.

- Mark the Site C1100 as Logistics Relevant so that the planning area is active as well.

- Once the subcontracting site is configured create two transport lanes connecting Main Site and the Subcontracting site. One lane should have Ship-From site as Main Site(P1100) and the Ship-To site as Subcontracting site (C1100). The second lane should have Ship-From site as Subcontracting site (C1100) and the Ship-To site as Main Site (P1100). These transport lanes will be used to ship the components to the subcontracting site and to ship finished product from subcontracting site.

- The Planning tab of the Final Product should be maintained as follows. Procurement type for Planning area P1100 should be Internal Procurement and for Planning Area C1100 should be In-house Production.

- The Planning tab settings for the raw materials in the planning area C1100 should have Procurement Type as Internal Procurement. In the planning area P1100 you can have the Procurement Type as either External Procurement or In-house Production depending on your business use case. I have maintained as External Procurement in this particular example.

- Create a Production Bill of Material and Production Model for the site C1100. I have used the below configuration for the BoM in this scenario.

- Output Product: MSCM_SUB

- Input Products : SUB_RAW_MATERIAL_01 and SUB_RAW_MATERIAL_02

Pre-existing condition:

- We have a demand of 5 qty for the product MSCM_SUB via a sales order. The product is shipped from our main site P1100.

Business Scenario Execution:

- Execute MRP for the Product MSCM_SUB for the planning area P1100. You can see that the system will create Supply via Stock transfer proposal to be shipped from C1100.

- Now, for the product MSCM_SUB, there will be a Stock Transfer dependent demand at the subcontracting site C1100. If you execute MRP for for the MSCM_SUB in C1100, the system will create a Production Proposal. There will be dependant demand for the raw materials "SUB_RAW_MATERIAL_01" and "SUB_RAW_MATERIAL_02" .

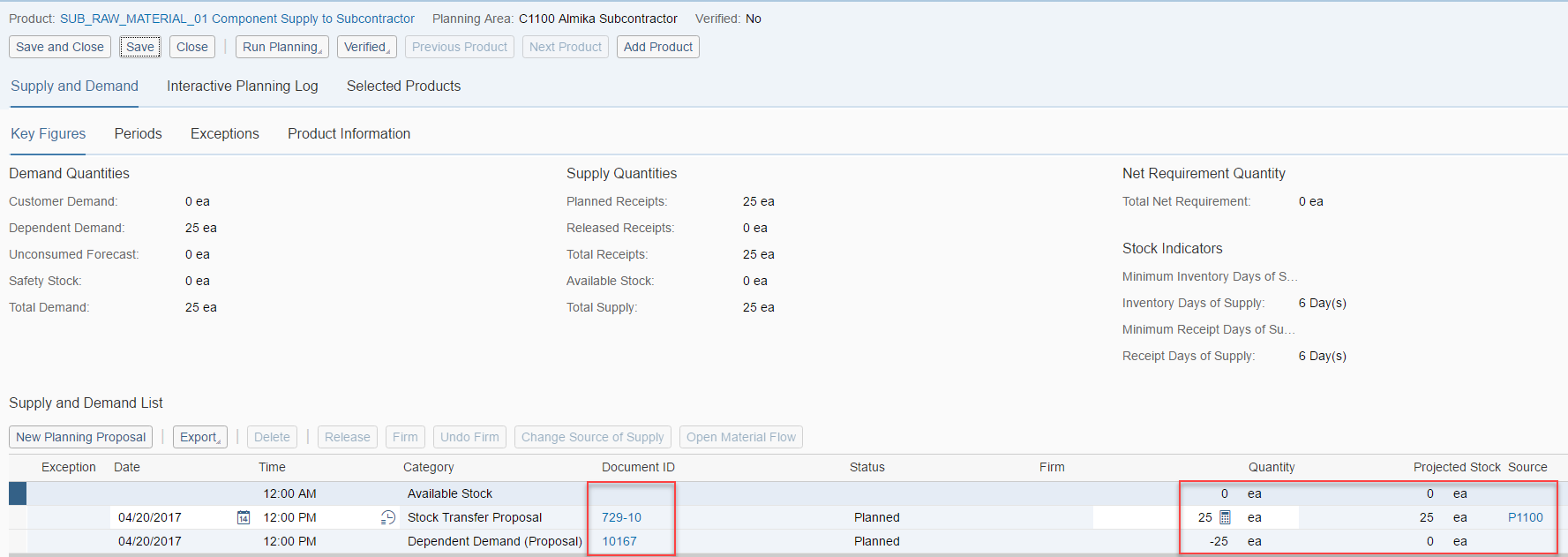

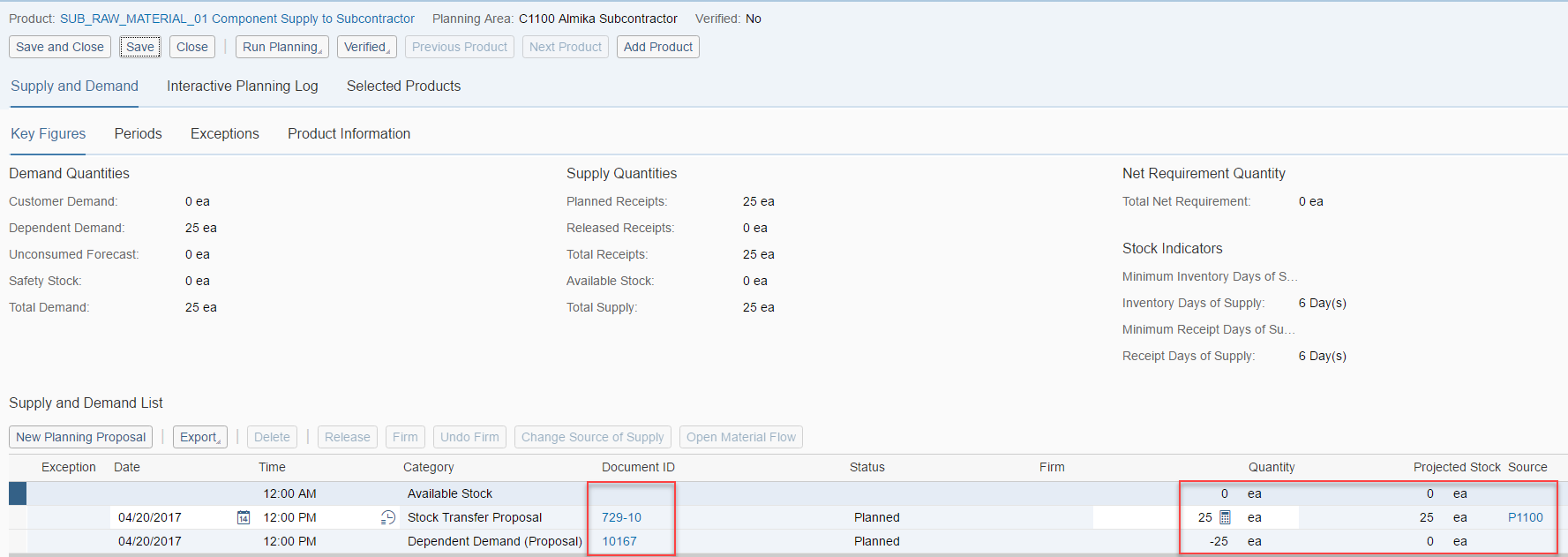

- Execute MRP for the raw-materials SUB_RAW_MATERIAL_01 and SUB_RAW_MATERIAL_02 at the site C1100. Stock transfer proposals will be created for the products.

- If the main site P1100 has stock of the item the components/ raw materials will be supplied to the subcontractor via the above created stock transfer proposals. If not on executing MRP for the raw materials at site P1100, the system will create supply as per the Procurement Type maintained for the planning area P1100 for the above components.

- Once the components are available at the subcontractor via the stock transfer proposals, the production proposal can be executed and production completed for the finished goods MSCM_SUB.

- Once the production is completed the final product will be supplied back to the main site P1100 via the stock transfer proposal that was created at the site initially.

The above steps will take care of the logistics part of your subcontracting process.

Payment to Subcontractor:

To pay the subcontractor you will have to create a purchase order with service item with your subcontractor as the supplier. You can create a supplier invoice against this purchase order and pay the subcontractor as per your agreement.

The above steps will help you execute the subcontracting business process in your ByD system. Please do reach out to me via the comments section for any more queries on the same.

Note : Please refer the Blog Subcontracting in SAP Business ByDesign – Part II to have a deeper look into how one could set up the system to better align the production process with the service purchasing process.

- SAP Managed Tags:

- SAP Business ByDesign,

- SAP Supply Chain Management

Labels:

32 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

23 -

Expert Insights

114 -

Expert Insights

151 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

205 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

85

Related Content

- ISD (Input Service Distributer) GST registration in Enterprise Resource Planning Q&A

- Information about SAP Business ByDesign Partner Tenant Delivery in Enterprise Resource Planning Q&A

- SAP Business ByDesign 2023 year-end review and outlook 2024 in Enterprise Resource Planning Blogs by SAP

- System Security Audit in Enterprise Resource Planning Q&A

- Merge two reports Sap bydesign in Enterprise Resource Planning Q&A

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 |