- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- #S4HANA 1610 use case series: 1b – advanced Availa...

Enterprise Resource Planning Blogs by SAP

Get insights and updates about cloud ERP and RISE with SAP, SAP S/4HANA and SAP S/4HANA Cloud, and more enterprise management capabilities with SAP blog posts.

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Employee

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

11-12-2016

1:16 PM

In the corresponding Business Value blog #S4HANA 1610 use case series: 1a – new advanced ATP (biz view) we have explained why it is essential to provide customers with requests for information on product availability, and how we will cover the last minute rush order.

Today´s blog will shed a light on what has changed with SAP S/4HANA 1610 from a technical point of view to address the key business challenges faced in the order fulfillment process to provide the customers with the available quantities of the requested product and the corresponding due dates for them to expect delivery. And for the records, this has been available in S/4 Cloud with 1608 already.

SAP offers different ATP Solutions - here you find the comparision

SAP ERP Central Component (SAP ECC) – Available-to-Promise (ATP)

SAP ERP Central Component’s (SAP ECC) Available-to-Promise (ATP) is the order fulfillment process that is designed to provide a commitment to customer-requested order quantities and dates based on availability of products, components, and resources. The Availability check ensures that there are enough components available for planned or production orders in production planning and production control. The Customizing is based on a combination of fields from the Materials Resources Planning (MRP) and Sales and Distribution (SD) views of the Material Master Record, for the most part. User exit on Delivery Proposal screen adds additional location searches.

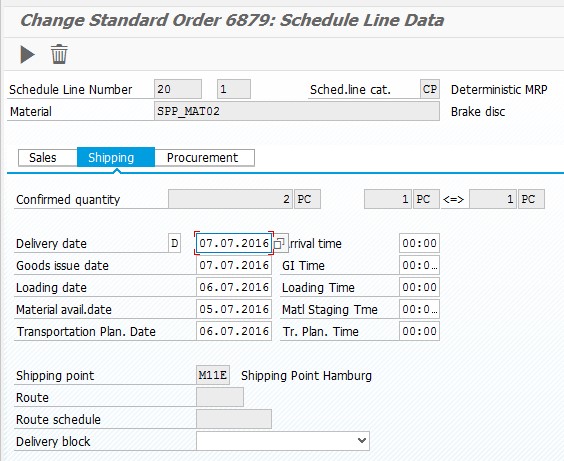

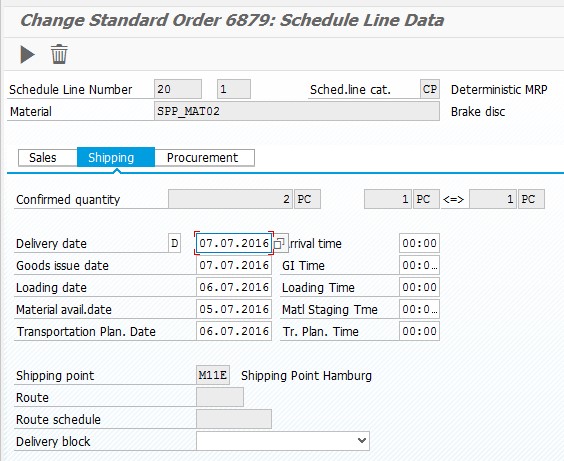

In the screen below, you see the different calculated dates as result of the availability check:

Transportation planning date: Date by which transportation must be arranged so that the delivery can reach the customer on time.

Material availability date: Date by which sufficient quantities of the item must be available for picking to begin. The system calculates the material availability date by working backwards from the customer's requested delivery date, taking into account how much time is needed for delivery-related procedures, such as picking, packing, loading, and transportation.

Loading date: Date by which picking and packing must be completed so that the goods are ready for loading and for the delivery to reach the customer on time.

Goods issue date: Date on which the goods must physically leave the shipping point to reach the customer on time.

Delivery date: The delivery date can be the date requested by the customer, or (if the requested date cannot be met) or the earliest date proposed by the system after automatic availability checks and delivery scheduling.

SAP Global Available-To-Promise (gATP).

The concept of available to promise used in Sales and Distribution (SD) module in SAP R/3 provides check capabilities that deliver results for basic business scenarios. More complex scenarios, however, require more robust capabilities to make delivery commitments that are in line with the real-world demands. In short, global scenarios require global solutions. SAP’s Advanced Planning & Optimization (SAP APO) Global Available-To-Promise (Global ATP) is implemented to take advantage of several advanced functionalities that standard SAP ECC does not provide, takes advantage of SAP APO technology and picks up where the SAP R/3 ATP solution leaves off.

The Global ATP in APO processes are run via SAP live Cache (a tool for processing large volumes of data in main memory, enabling data sharing among several applications), which processes large volumes of data and enables data sharing across several applications. gATP meets the challenge of providing availability information across a global enterprise.

As the creation and maintenance of master data are done in the execution system, a data transfer is necessary and any master data changes in order that this master data is available in the planning functions of SAP Advanced Planning and Optimization (SAP APO). The data is transferred via the Core Interface (CIF) and the same master data situation exists in both systems (see Technical Architecture picture).

Technical Architecture for Global Consolidation of SAP ERP and Global ATP Systems

Simplification by process innovation with SAP S/4HANA 1610

The new advanced ATP (aATP) within SAP S/4HANA 1610 runs entirely on the in-memory platform SAP HANA which has been optimized and improved the overall performance. The internal logic to read the planning elements from the database to the internal table has been fully redesigned to run in-memory planning. In the same way, SAP S/4HANA 1610 use the innovations and the new inventory data model done with SAP S/4HANA, on premise edition 1511 (see 1511 use case blog 2b – next generation inventory management (tech view)).

With SAP S/4HANA 1610, we are introducing the advanced ATP integrated into S/4HANA core, and the goal here is clearly not to integrate the gATP in SAP S/4HANA, but to develop a more efficient ATP system supporting this dynamic digital world in which more complex mechanisms are necessary for varied production, variable demand and multiple stock localizations.

In this first release, the focus was on three topics:

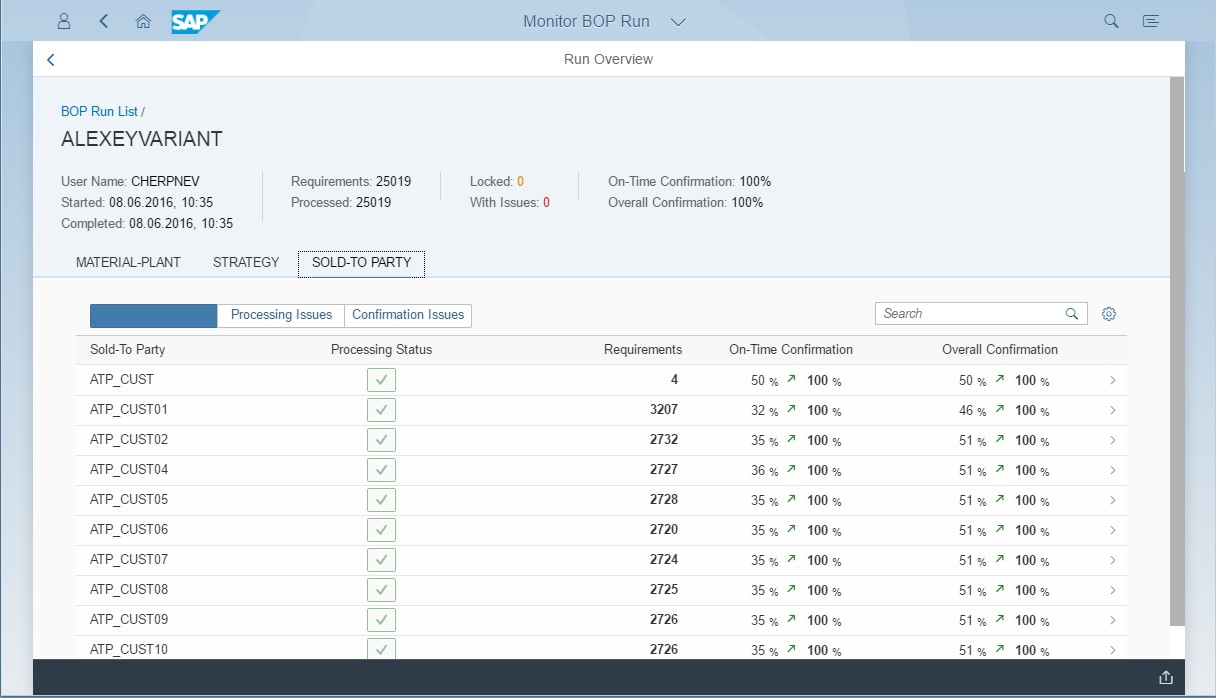

The all new advanced BOP is based on a multi-step filter & prioritizer.

Each pair of filter & prioritizer is called a BOP segment definition and defines a requirement list which is sorted according to a free set of order attributes. All requirements of a given BOP segment have the same semantics which is called confirmation strategy. There are five different predefined confirmation strategies: Win, Gain, Redistribute, Fill and Lose. It is possible to have multiple BOP segments of the same confirmation strategy. Each BOP run is based on a so called BOP variant and needs at least one BOP segment definition but it might have many more. Each requirement which is ATP-checked during the one BOP variant.

Additionally the selection can be restricted by a global filter of the BOP variant. Using a global filter means that each individual segment definition can be kept very simple and purely based on parameters which are related to the business meaning of that very segment. In contrast, the global filter is expected to be more technical, defining the relevant material/plant-combination according to their specific attributes or aligned with organizational selection criteria.

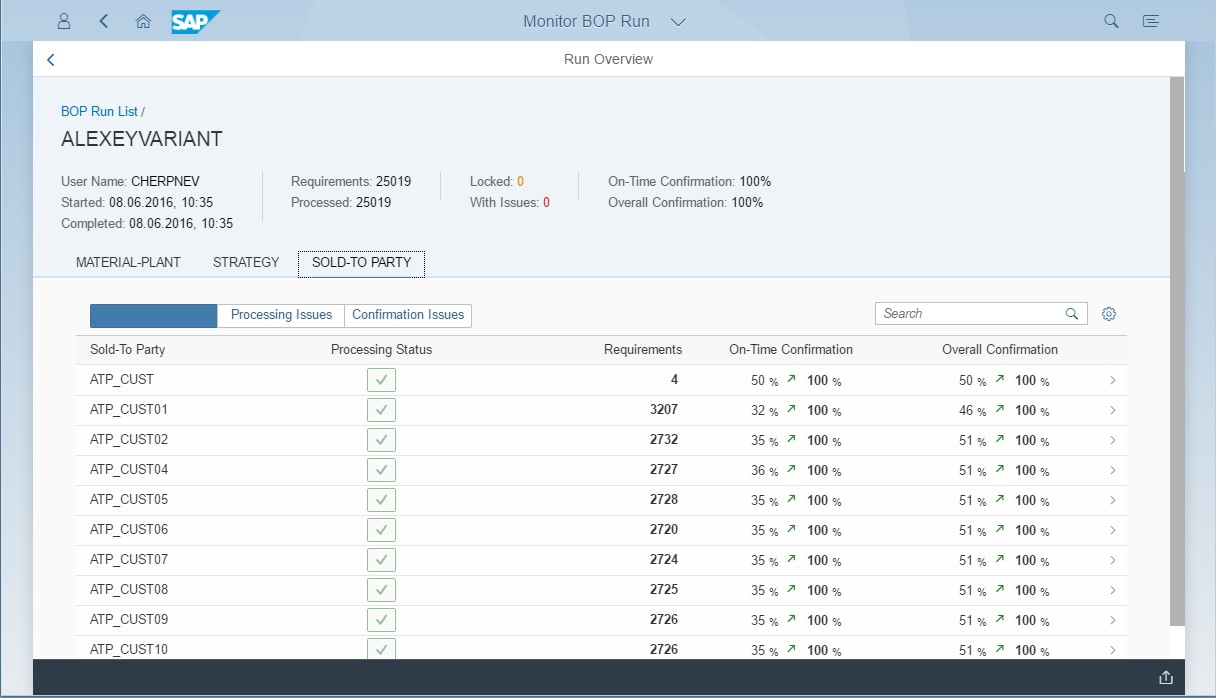

Screenshot: BOP-Result

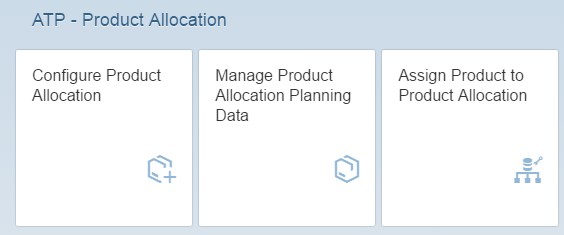

The Product Allocation in SAP S/4HANA has a completely new design and implementation based on neither SAP ECC nor APO

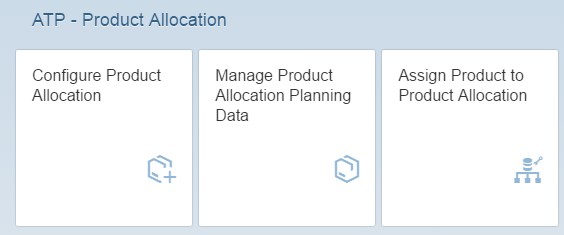

One of the key innovation concerning the Product Allocation is that we simplified the way end –user can customize the process. Before, you needed to customize in SPRO. With SAP S/4HANA 1610, we compile 36 Transactions in 3 easy to use Apps and we reduced the number of customizing and data maintenance steps needed to setup the product allocation functionality

Simplified Set-Up: 3 easy to use Apps

In this innovation, we modified the way how end-user works with the system. Indeed, the work is facilitated and the user can directly see the material shortage and the end-user can focus its work on what's wrong.

Screenshot: SAP Fiori: Release for delivery app

This SAP Fiori app allows the end-user to review critical shortages and the result, to easily gate keep which sales order requirements should be delivered.

Especially designed for handling material shortage situations this highly interactive SAP Fiori app enables any user to efficiently distribute the available stock to the most important sales order requirements.

To see the long-term vision and evolution path for the advanced available to promise in SAP S/4HANA, have a look at our roadmap on the SAP Portal.

Looking forward meeting you at our next blog talking about the business view concerning the retail industry for SAP S/4HANA 1610.

Stay tuned for the next use cases and follow me via @SDenecken for latest news.

__________________________________________________________________________________________________________

Here the link to Part 1a:

https://blogs.sap.com/2016/11/10/s4hana-1610-use-case-series-1a-advanced-availability-to-promise-biz...

Link to the series:

https://blogs.sap.com/2016/11/09/s4hana-1610-use-case-series-intro/

Today´s blog will shed a light on what has changed with SAP S/4HANA 1610 from a technical point of view to address the key business challenges faced in the order fulfillment process to provide the customers with the available quantities of the requested product and the corresponding due dates for them to expect delivery. And for the records, this has been available in S/4 Cloud with 1608 already.

SAP offers different ATP Solutions - here you find the comparision

SAP ERP Central Component (SAP ECC) – Available-to-Promise (ATP)

SAP ERP Central Component’s (SAP ECC) Available-to-Promise (ATP) is the order fulfillment process that is designed to provide a commitment to customer-requested order quantities and dates based on availability of products, components, and resources. The Availability check ensures that there are enough components available for planned or production orders in production planning and production control. The Customizing is based on a combination of fields from the Materials Resources Planning (MRP) and Sales and Distribution (SD) views of the Material Master Record, for the most part. User exit on Delivery Proposal screen adds additional location searches.

In the screen below, you see the different calculated dates as result of the availability check:

Transportation planning date: Date by which transportation must be arranged so that the delivery can reach the customer on time.

Material availability date: Date by which sufficient quantities of the item must be available for picking to begin. The system calculates the material availability date by working backwards from the customer's requested delivery date, taking into account how much time is needed for delivery-related procedures, such as picking, packing, loading, and transportation.

Loading date: Date by which picking and packing must be completed so that the goods are ready for loading and for the delivery to reach the customer on time.

Goods issue date: Date on which the goods must physically leave the shipping point to reach the customer on time.

Delivery date: The delivery date can be the date requested by the customer, or (if the requested date cannot be met) or the earliest date proposed by the system after automatic availability checks and delivery scheduling.

SAP Global Available-To-Promise (gATP).

The concept of available to promise used in Sales and Distribution (SD) module in SAP R/3 provides check capabilities that deliver results for basic business scenarios. More complex scenarios, however, require more robust capabilities to make delivery commitments that are in line with the real-world demands. In short, global scenarios require global solutions. SAP’s Advanced Planning & Optimization (SAP APO) Global Available-To-Promise (Global ATP) is implemented to take advantage of several advanced functionalities that standard SAP ECC does not provide, takes advantage of SAP APO technology and picks up where the SAP R/3 ATP solution leaves off.

The Global ATP in APO processes are run via SAP live Cache (a tool for processing large volumes of data in main memory, enabling data sharing among several applications), which processes large volumes of data and enables data sharing across several applications. gATP meets the challenge of providing availability information across a global enterprise.

As the creation and maintenance of master data are done in the execution system, a data transfer is necessary and any master data changes in order that this master data is available in the planning functions of SAP Advanced Planning and Optimization (SAP APO). The data is transferred via the Core Interface (CIF) and the same master data situation exists in both systems (see Technical Architecture picture).

Technical Architecture for Global Consolidation of SAP ERP and Global ATP Systems

Simplification by process innovation with SAP S/4HANA 1610

The new advanced ATP (aATP) within SAP S/4HANA 1610 runs entirely on the in-memory platform SAP HANA which has been optimized and improved the overall performance. The internal logic to read the planning elements from the database to the internal table has been fully redesigned to run in-memory planning. In the same way, SAP S/4HANA 1610 use the innovations and the new inventory data model done with SAP S/4HANA, on premise edition 1511 (see 1511 use case blog 2b – next generation inventory management (tech view)).

With SAP S/4HANA 1610, we are introducing the advanced ATP integrated into S/4HANA core, and the goal here is clearly not to integrate the gATP in SAP S/4HANA, but to develop a more efficient ATP system supporting this dynamic digital world in which more complex mechanisms are necessary for varied production, variable demand and multiple stock localizations.

In this first release, the focus was on three topics:

- New confirmation strategy in the back-order processing (BOP)

The all new advanced BOP is based on a multi-step filter & prioritizer.

Each pair of filter & prioritizer is called a BOP segment definition and defines a requirement list which is sorted according to a free set of order attributes. All requirements of a given BOP segment have the same semantics which is called confirmation strategy. There are five different predefined confirmation strategies: Win, Gain, Redistribute, Fill and Lose. It is possible to have multiple BOP segments of the same confirmation strategy. Each BOP run is based on a so called BOP variant and needs at least one BOP segment definition but it might have many more. Each requirement which is ATP-checked during the one BOP variant.

Additionally the selection can be restricted by a global filter of the BOP variant. Using a global filter means that each individual segment definition can be kept very simple and purely based on parameters which are related to the business meaning of that very segment. In contrast, the global filter is expected to be more technical, defining the relevant material/plant-combination according to their specific attributes or aligned with organizational selection criteria.

Screenshot: BOP-Result

- Product allocation process

The Product Allocation in SAP S/4HANA has a completely new design and implementation based on neither SAP ECC nor APO

One of the key innovation concerning the Product Allocation is that we simplified the way end –user can customize the process. Before, you needed to customize in SPRO. With SAP S/4HANA 1610, we compile 36 Transactions in 3 easy to use Apps and we reduced the number of customizing and data maintenance steps needed to setup the product allocation functionality

Simplified Set-Up: 3 easy to use Apps

- Release for delivery (SAP Fiori app)

In this innovation, we modified the way how end-user works with the system. Indeed, the work is facilitated and the user can directly see the material shortage and the end-user can focus its work on what's wrong.

Screenshot: SAP Fiori: Release for delivery app

This SAP Fiori app allows the end-user to review critical shortages and the result, to easily gate keep which sales order requirements should be delivered.

Especially designed for handling material shortage situations this highly interactive SAP Fiori app enables any user to efficiently distribute the available stock to the most important sales order requirements.

To see the long-term vision and evolution path for the advanced available to promise in SAP S/4HANA, have a look at our roadmap on the SAP Portal.

Looking forward meeting you at our next blog talking about the business view concerning the retail industry for SAP S/4HANA 1610.

Stay tuned for the next use cases and follow me via @SDenecken for latest news.

__________________________________________________________________________________________________________

Here the link to Part 1a:

https://blogs.sap.com/2016/11/10/s4hana-1610-use-case-series-1a-advanced-availability-to-promise-biz...

Link to the series:

https://blogs.sap.com/2016/11/09/s4hana-1610-use-case-series-intro/

- SAP Managed Tags:

- SAP S/4HANA,

- User Interface

7 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

20 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

22 -

Expert Insights

114 -

Expert Insights

147 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,687 -

Product Updates

200 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

85

Related Content

- SAP Fiori for SAP S/4HANA – Upgrade Faster – Managing app lifecycle impacts on users in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release – Part 1 in Enterprise Resource Planning Blogs by SAP

- Is it possible to use Product Allocation only with S140 since it doesnt have material number ? in Enterprise Resource Planning Q&A

- Enhancements, evolutions, and enabled innovations across SAP’s Public Sector solution portfolio in Enterprise Resource Planning Blogs by SAP

- Deletion of Master and Transactional Data (ILM) in SAP S/4HANA Cloud,Public Edition-Link Collection in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 5 | |

| 5 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 3 | |

| 3 |