- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- How to Manage Your Profitability in Contract Manuf...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Contract manufacturing (CM) industries are typically characterized by a combination of two critical factors: a) slim margins and b) mass productions with contracts running for several years. These characteristics are associated with significant risks that add up to the highly competitive global markets of today´s economy. If manufacturing businesses want to survive under these conditions, CEOs and CFOs need to make profitability management a top priority in their business operations.

But how can contract manufacturing businesses tackle this challenge? Working and co-innovating with our customers in contract manufacturing and precision engineering, we have developed an integrated process to connect relevant data from their Enterprise Resource Planning (ERP) and Configure Price Quote (CPQ) system in order to feed analytics for detailed profitability insights. Supporting the management and enhancing their decision making processes with ad-hoc reports and analytics capabilities is key in profitability management.

The challenges of the contract manufacturing industry

Contract manufacturers are highly dependent on the contractor. After having submitted his quotation, the contract manufacturer's sell price is more or less fixed. Consequently, also the maximum profitability that could be achieved for this order is fixed and it rarely turns out the products can be produced cheaper than expected. However, the real costs to occur are not fully determined yet as the production often runs for several years, so you have to account for several risks during that period.

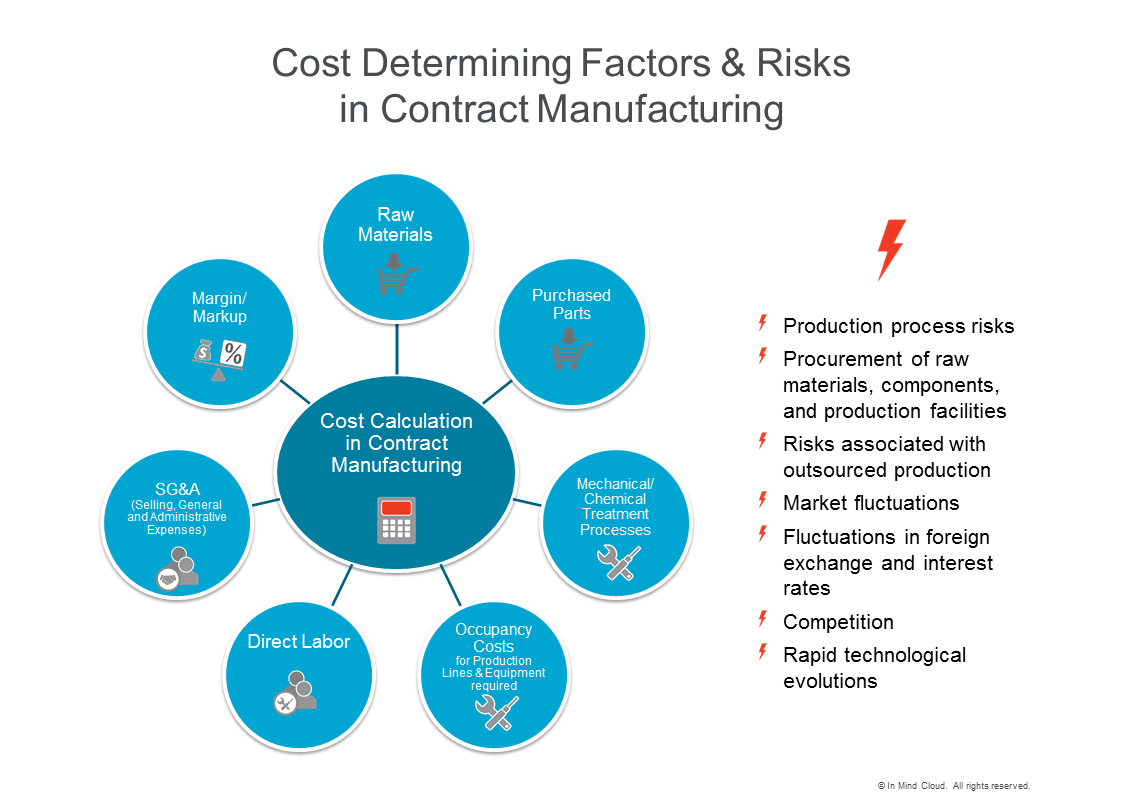

Some of these business risks include:

- Production process risks

- Procurement of raw materials, components, and production facilities

- Risks associated with outsourced production

- Market fluctuations

- Fluctuations in foreign exchange and interest rates

- Competition

- Rapid technological evolutions

For our customers these circumstances are part of their business risks. The question is how they are opting to mitigate these risks. Let me go back to the root of the process and see how a price calculation works and a profit can be achieved. In order to determine the sell price in contract manufacturing the companies usually apply a "cost plus approach". They are attempting to determine the costs of the parts that they are producing by adding up the material cost, additional purchase parts (e.g. screws), processes (machines), labor and further subcontracting costs. On top of those costs and on different levels multiple markups are applied in order to achieve a margin.For a quick understanding and sample calculations on markups read this source explaining the calculation scheme.

This approach generally is perceived as best-practice for this industry and is widely used. Unfortunately risk factors such as production volatility and further business changes have a negative effect on profitability. So how can you reduce the risks of a decreased profitability?

Overcoming the challenges to increase profitability

In our year long experience in working with contract manufacturing businesses, we have developed the following approach to address this challenge:

- Connecting the quotation process with ERP data to gain transparency over the cost, revenue and profit from quotation till production lifespan

- Presenting real-time insights to the management on the profitability of the company, plant or project

- Establishing a unified financial reporting in order to focus on one unified key metric

- Empowering better business decision making, based on facts from actual and past data in order to maintain or increase the profitability

The solution: Leveraging insights from connecting CPQ and ERP

Our integrated approach to measure and improve the profitability evolved into the strategy of leveraging insights from connecting CPQ (Configure Price Quote) and ERP data via the following steps:

- Estimate costs and apply markups during the RFQ (Request for Proposal) process. Move accepted quotes including their new materials directly to the ERP system

- Measure actual costs in the ERP system

- Perform analytics comparing the planned costs from the initial CPQ /RFQ calculation to the actual costs in the ERP

- Optimize parameters for future quotes

1. Costing in Configure Price Quote processes

First of all, the sales and project management team would assess the OEM's (Original Equipment Manufacturer) requirements of the products to be manufactured. An integrated CPQ system enables the team to create the BOM (Bill of Material) of the product, including the required materials and manufacturing processes. Often multiple departments are involved in determining the right costing. For Example, SCM (Supply Chain Management) would be responsible to capture the costs of all purchasing materials, whilst engineering departments contribute their process knowledge. You can read more about that in my last post about why a standard CRM doesn’t help contract manufacturing industries.

2. Measure Costs in ERP

Once a quote is accepted the cost estimates need to move to the ERP system which is used for capturing the actual costs. As in most cases new materials need to be created for a quote, this is naturally a slow and highly manual process. Hence, it is a huge advantage when the CPQ system can automate this task and create the material in the ERP, together with its BOM (Bill of Material) and the ERP Routing of the machines. With this automatism in place, the sales order can be generated, containing the sell price and the estimated quantity of the product.

3. Perform analytics comparing the planned costs from CPQ with the actual costs in ERP

The planned costs from the quotation stage are already available in the CPQ system. Additionally, the actual costs from ERP are delivered to the CPQ analytics tool. Creating the parts in ERP by the CPQ establishes a link between the actual costs and the planned costs. Consequently, also the actual profit and planned profit can be compared. Key values to be extracted are the actual sales quantity, actual costs and actual selling price. As commonly known, in production planning the actual costs will almost always differ from the estimated ones. But the important question is whether they are higher or lower. So analytics need to be performed which combine the estimation data from CPQ and the actual production data from ERP. This provides the full transparency over the project lifespan. Usually there are multiple price points negotiated depending on the order quantity. Running often in batches amortizing the fix costs for setups on more parts is important. Still the profitability can change over the time of the project due to multiple reasons e.g.:

- Purchase part prices change

- Other machines for production are used than in the quotation

- Lot size is smaller than expected

It is especially important to see if there are significant systematic anomalies between quoted and actual costs for segmenting customers, regions or single projects. The analytics provide interesting findings, also when comparing the profit over different periods of the production time span.

If you are interested in other analytics that can be performed in a CPQ system for contract manufacturing have a look at https://www.inmindcloud.com/how-to-predict-your-revenue/

4. Optimize parameters for future quotes.

After gaining those insights, we are now aware of the profitability change between quoted and actual project. The advantage of the presented approach is a closed cycle with analytics at the last step connecting to the sales process in the first step, both being executed in the CPQ system. The insights from the analytics can translate into direct actions for future quotes to increase the profitability. It would also be possible to analyze the differences in a BI (Business Intelligence) tool that is fed by the CPQ and ERP system but integration would be lacking.So now it’s time to act on those discovered differences.

- Sales people can be told to apply higher mark ups (or this can be defaulted) for specific customers for whom discrepancies are discovered.

- Finance department can change the rates for machines when they realize that those don’t match the reality anymore or a higher buffer is needed.

- Changes in quoted and ordered quantity need to be controlled better in the contact.

The other way around it also gives sales people flexibility when they know that some customers are more profitable than expected and in competitive situation they can provide additional discounts in order to get the deal.

Conclusion

The integrated approach of connecting CPQ and ERP data helps all companies who operate in contract manufacturing to estimate the costs of a yearlong lasting production and mitigate related risks. Multiple insights empower CEOs and CFOs to act on cost differences and learn from data of the past.

After having optimized the sales process in terms of efficiency and accuracy through a state-of-the-art Configure Price Quote system, the connection of sales data with production data from the ERP system becomes a necessity to govern profitability and be ahead of competition in fiercely contested markets.

Running a smooth business nowadays is not enough for contract manufacturing companies, CEOs and business owners need to monitor the profitability of their business in real-time in order to move ahead of competition and retain customers for the future.

- SAP Managed Tags:

- SAP ERP,

- MAN (Manufacturing)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Customizing

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

How to add new Fields in the Selection Screen Parameter in FBL1H Tcode

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

Ledger Combinations in SAP

1 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

POSTMAN

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

S4HANACloud audit

1 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP CI

1 -

SAP Cloud ALM

1 -

SAP CPI

1 -

SAP Data Quality Management

1 -

SAP ERP

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

Time Management

1 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Preferred Success Round Table Discussion with SAP Customers on 29th April @ SAP NOW India. in Enterprise Resource Planning Blogs by SAP

- Recap of SAP S/4HANA 2023 Highlights Webinar: Service in Enterprise Resource Planning Blogs by SAP

- Recap of SAP S/4HANA 2023 Highlights Webinar: Sales in Enterprise Resource Planning Blogs by SAP

- Recap of SAP S/4HANA 2023 Highlights Webinar: Overview - Gen AI and Sustainability in Enterprise Resource Planning Blogs by SAP

- SAP S4HANA Cloud Public Edition Logistics FAQ in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |