- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- SAP EAM - FICO Integration

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Introduction

Purpose of this document is to share SAP PM - FICO integration insights. There are multiple integration points between SAP PM & FICO.

Topics covered in this document. All basic configuration settings are mentioned in this document and other integration points are mentioned in brief.

- EAM - MM Integration

- EAM - MM - FICO Integration

- EAM - FICO Integration

Note : PM - FICO integration using PS module is not covered in this document.

EAM - MM Integration Points :

- Non-Stock Materials : To create a PR directly from a Work order.

- Material Reservations : For Stock materials to be reserved against a Work order

- Bill Of material : for setting up BOM for Functional location & Equipment

- Material Availability check : Material availability check number should be available in material master record ( MRP 3 View)

- Serial Number profile for Material & Auto generation of Equipment with default equipment category maintained in Serial number profile.

EAM - MM - FICO Integration Points :

- PR creation from Work Order - Accounting data for a external procurement ,Service maser record etc.

- Material master record for batch managed material

- Material Valuation class & Valuation type for Refurbishment process

- Goods issuance : Moving average price for a material during goods issuance.

EAM - FICO Integration Points :

- Activity Based costing for calculations of Labor cost for a Work Order

- Work Order settlement - Settlement Profile

- Cost Analysis reporting

Basic Configurations required for EAM-FICO Integration

(Note - In this document, one to one mapping for Company code & Plant is considered)

Pre-requisites : 1) Assign controlling area to company code

2) Maintain Number ranges for controlling

1) Define Cost component Structure :

SPRO Path : Controlling - Product Cost Controlling - Product Cost Planning - Basic Settings for Material Costing - Define Cost Component Structure.

Description : Cost component structure determines how the results of material costing are updated. The cost component structure groups the costs for each material according to cost component (such as material costs, internal activities, external activities, and overhead). If the material is used in the production of another material.

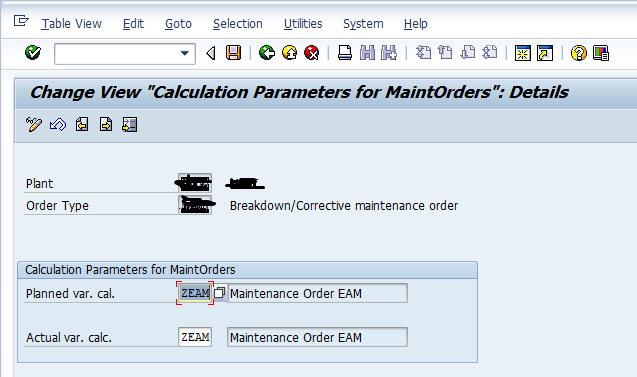

2) Maintain Costing variants :

SPRO Path : Plant Maintenance and Customer Service - Maintenance and Service Processing - Maintenance and Service Orders - Functions and Settings for Order Types - Costing Data for Maintenance and Service Orders - Maintain Costing Variants

Description : The costing variant determines how costing is carried out. All Cost estimates are created & Saved with reference to costing variant only. Please refer to F1 help for detailed explanation.

3) Define Valuation Variants :

Path : Plant Maintenance and Customer Service - Maintenance and Service Processing - Maintenance and Service Orders - Functions and Settings for Order Types - Costing Data for Maintenance and Service Orders - Define Valuation Variants

Description : Assign valuation variant to Plant for material and plant level valuation purposes. You use the Valuation Variant to specify the following things.

- Which prices are used to valuate the material components

- Which prices are used to valuate the internal activities and business processes

- Which plan version is used

- Which prices are used to valuate external processing of an assembly or operation

- Which costing sheet is used to calculate overhead

4) Assign Costing Parameters to result analysis key

Path : Plant Maintenance and Customer Service - Maintenance and Service Orders - Functions and Setting for Order Types - Costing Data for Maintenance and Service Orders - Assign Costing Parameters and Results Analysis Keys

Description : In this Step, you assign Costing variant to Plant - Order type combination as shown below.

5) Maintain Value Categories :

Path : Plant Maintenance and Customer Service - Maintenance and Service Processing - Basic Settings - Settings for Display of Costs - Maintain Value Categories.

Description : Value categories are nothing but an interval of cost elements with respect to your controlling area. You define these value categories to display grouped cost into an Work order.

6) Assign value categories :

Path : Plant Maintenance and Customer Service - Maintenance and Service Processing - Basic Settings - Settings for Display of Costs - Assign Cost Elements to Value Categories

Description : Here you assign cost elements to your value categories created in above steps as shown below.

7) Define version for Cost elements for orders

Path : Plant Maintenance and Customer Service - Maintenance and Service Processing - Basic Settings - Settings for Display of Costs - Define Version for Cost Estimates for Orders

😎 Define Default values for Value categories :

Path : Plant Maintenance and Customer Service - Maintenance and Service Processing - Basic Settings - Settings for Display of Costs - Define Default Values for Value Categories

Example : Labor cost, Material cost etc.

9) Define currency for Maintenance statistics :

Path : Plant Maintenance and Customer Service >Information Systems for Plant Maintenance and Customer Service --> Define Currency for Maintenance Statistics

Description : In this step, you can define in which currency plant maintenance statistical data is managed. The following points are to be considered when defining the currency for the maintenance statistics.

- The currency chosen applies to the entire client.

- All of the fields in Plant Maintenance that are currency-dependent and are used for statistical data are translated automatically into the currency for statistics.

- The date with which the exchange rate is calculated is field-related and determined by the system, and cannot be changed. The equipment acquisition date is taken as a basis for translating the acquisition value and the posting date of the individual order documents is taken as a basis for translating the value fields of a maintenance order.

10) Maintain Cost key figures :

Path : Plant Maintenance and Customer Service >Information Systems for Plant Maintenance and Customer Service --> Assign Value Categories to Maintenance Cost Key Figures

Note : In this section, you can allocate value categories to PM cost key figures predefined by SAP. The value category generally groups several cost element accounts together.

11) Maintain Settlement Profile :

Path : Plant Maintenance and Customer Service - Maintenance and Service Processing - Basic Settings - General Order Settlement - Maintain Settlement Profiles.

Note : If you want to settle the costs each time to just one cost center or just one G/L account, you need a settlement profile. As you cannot maintain the settlement parameters during settlement to a receiver, you must save the settlement profile in the order type.

In Settlement profile you have options to define criteria for settlement receiver, Default object type for settlement etc.

12) Maintain Allocation Structure :

Path : Plant Maintenance and Customer Service -> Maintenance and Service Processing -> Basic Settings -> General Order Settlement -> Maintain Allocation Structure

Description : During settlement, costs incurred under the primary and secondary Cost elements by a sender are allocated to one or more receivers. When you settle by cost element, you settle using the appropriate original cost element. An Allocation Structure comprises one or several settlement assignments.

An assignment shows which costs (origin: cost element groups from debit cost elements) are to be settled to which receiver type (for example, cost center, order, and so on). You have two alternatives in settlement assignment:

- You assign the debit cost element groups to a settlement cost element.

- You settle by cost element - that is, the debit cost element is the settlement cost element.

- This is a good idea, for example, if the required capital spending for an asset you are building yourself is to be monitored. These costs are settled by cost element to an inventory account in Asset Accounting at the end of the year, or when the measure is complete.

13) Automatic Settlement Rule assignment :

Path : Plant Maintenance and Customer Service - Maintenance and Service Processing - Maintenance and Service Orders - Functions and Settings for Order Types - Settlement Rule : Define Time and Creation of Distribution Rule.

- SAP Managed Tags:

- PLM Enterprise Asset Management (EAM)/Plant Maintenance (PM)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Peppol Integration Scenario Generates Inconsistencies in Enterprise Resource Planning Q&A

- SAP Master Data Integration issue for Subscription Billing with SAP S/4HANA Public Cloud in Enterprise Resource Planning Q&A

- Update of the SAP Activate Roadmap for SAP S/4HANA (on prem) upgrades with the Clean Core Strategy in Enterprise Resource Planning Blogs by SAP

- Business Volume Report shows Billing Documents that do not accrue to the contract in Enterprise Resource Planning Q&A

- Integration of SAP Service and Asset Manager(SSAM) with SAP FSM to support S/4HANA Service Processes in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |