- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Special Movement Indicator

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Special Movement Indicator:

It is always possible to influence the movement of material within WM via the special movement indicators. You can assign another movement type in the Warehouse Management System (WMS) to a movement type from Inventory Management using this indicator.

Since you can specify interim storage areas and interim storage bins within the WM movement types, you can determine which interim storage areas and bins will be selected in WM for a goods movement depending upon the special movement indicator used. You can thereby actively influence the interface between Inventory Management (IM) and Warehouse Management (WM).

CONFIGURATION

First Step:

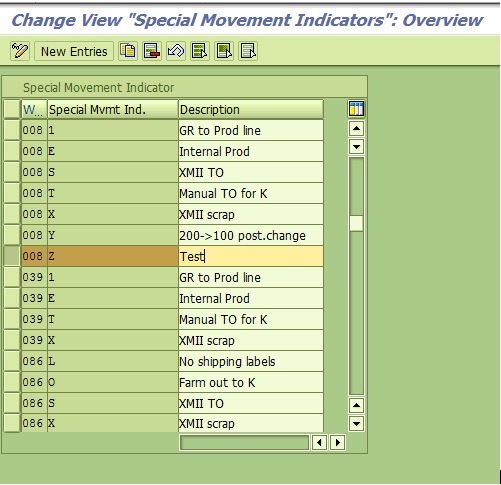

As a part of Configuration, First Step is to Create the Special Movement Indicators in the below Path:

Logistics Execution --> Warehouse Management --> Master Data --> Material --> Define Special Movement Indicators

Created Special Movement Indicator ‘Z’ – Test.

Second Step: Assign the WM Movement type to the newly selected Special Movement Indicator.

First assign the reference Movement type to Inventory Management Movement type

Logistics Execution --> Warehouse Management --> Interfaces --> Inventory Management --> Define Movement types --> Assign WM Movement Type References to IM Movement Types

IM Movement type 101 is assigned to Reference Movement type 101.

Then Assign the Warehouse Management reference to the Warehouse Management Movement type.

Logistics Execution --> Warehouse Management --> Interfaces --> Inventory Management --> Define Movement types --> LE-WM Interface to Inventory Management

WM Movement type 105 is assigned to the reference movement type 101 for Movement Indicator B Warehouse 008.

For the 101 Movement type at Inventory level, the Warehouse Movement would be 105 for all Materials with Special Movement indicator ‘Z’ . For others it would be 101.

Step 3: Define Warehouse Movement type

Now Define the Warehouse Movement # 105 as per your requirements.

Logistics Execution --> Warehouse Management --> Activities --> Transfers --> Define Movement types

Step 4: Define the Storage type Strategies to determine the receiving Storage type based on the Reference storage type search as defined the Warehouse Movement type.

In the below Config, I have assigned Storage type EXW for Warehouse 008, Storage type Indicator 200 and Reference Storage type search 105

Logistics Execution --> Warehouse Management --> Strategies --> Activate Storage type Search

Master Data

Maintain the below settings in the Material Master [WM View 1] for the warehouse# 008 as per above Configuration.

Special Movement Indicator – Z and the Storage type Indicator for Stock Placement – 200

With the above Configuration and the Master data, All the Materials received with Special Movement Indicator ‘Z’ would move in to Storage type EXW.

- SAP Managed Tags:

- LE (Logistics Execution)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Issue to asset from Project stock(Q) in Enterprise Resource Planning Q&A

- SAP S/4HANA Cloud Public Edition 财务-应收应付会计常见热点问题汇总FAQ in Enterprise Resource Planning Blogs by SAP

- User Experience in SAP S/4HANA Cloud Public Edition: New Microlearning Available in Enterprise Resource Planning Blogs by SAP

- Continuous Influence Session SAP S/4HANA Cloud, private edition: Results Review Cycle for Q4 2023 in Enterprise Resource Planning Blogs by SAP

- Negative Stock Handling in Enterprise Resource Planning Blogs by Members

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |