- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Pegging Area Inconsistencies in SAP APO PPDS

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Introduction

Pegging is a concept in SAP APO Production Planning and Detailed Scheduling (PP/DS) to 'link' a receipt element with a requirement element.

A Pegging Area in the context of SAP APO PP/DS is a combination of product, location, account assignment object and planning version.

The concept of pegging area in APO is similar to the concept of 'Planning Segment' in SAP ECC (does not include planning version). The concept can be understood in most simple manner in the following way. A requirement as well as a receipt element lies in a specific "pegging area". Only a receipt element which lies within the same pegging area as that of a requirement element, can be assigned to it.

Pegging relationships are of two types:

- Fixed Pegging – if used, fixed pegging relationships are retained even if there are document changes; it also keeps component assignment stable over multiple levels.

- Dynamic Pegging – system does automatic pegging and can change it in situations for example when a new requirement or receipt element is created.

Pegging is an important concept during detailed scheduling. Using ‘Detailed Scheduling Strategy’ we can define if system should consider pegging relationship; not using which could result in availability dates either too late or too early.

While pegging areas play an important role in APO PP/DS, sometimes system encounters "inconsistencies" in pegging areas. In below section we go through how to deal with pegging areas inconsistencies. Cleaning up inconsistent or obsolete pegging areas results in improved system performance.

Pegging areas inconsistencies

Pegging areas inconsistencies could be because of multiple reasons:

- Pegging areas without Orders [in Make to Order (MTO) production]

- Pegging areas without Account Assignment Objects (in MTO Production)

- Pegging areas without Product Master

- Pegging areas without Planning Version

- Pegging areas without Model

In the next section we shall go through method to deal with these inconsistencies.

How to deal with pegging areas inconsistencies

SAP has provided a standard report to remove pegging areas inconsistencies: /SAPAPO/DM_PEGKEY_REORG

The program’s behavior in case of different types of inconsistencies are described as below:

- Pegging areas without orders: The program deletes these pegging areas for which there are no orders. (In MTO Production)

- Pegging areas without account assignment objects: The program deletes such pegging areas only if these have no firmed orders. If there are firmed orders, then this program does not delete the pegging areas or the orders. (In MTO Production)

- Pegging areas without product master: The program deletes such pegging areas along with all unfirmed orders.

- Pegging areas without planning version: The program deletes such pegging areas along with all unfirmed orders.

- Pegging areas without model: These are pegging areas for which location products are not assigned to the model. The program deletes a pegging area if no requirement and receipt elements are existing which use this pegging area. If there exists such requirement or receipt, then we need to re-assign the locationproduct to the model in order to resolve this inconsistency.

The other three fields available for use in the program are as follows:

- Account assignment objects without pegging area or operations: (Used in MTO production): System deletes such account assignment objects for which there are no pegging areas or operations.

- Forecast consumption flag: Used to delete flags which system has put for consumption of forecast, for which there are no longer any pegging areas.

- Stock history: To delete stock history.

Removing Inconsistencies:

Go to SE38 transaction and put Program name: /SAPAPO/DM_PEGKEY_REORG and execute:

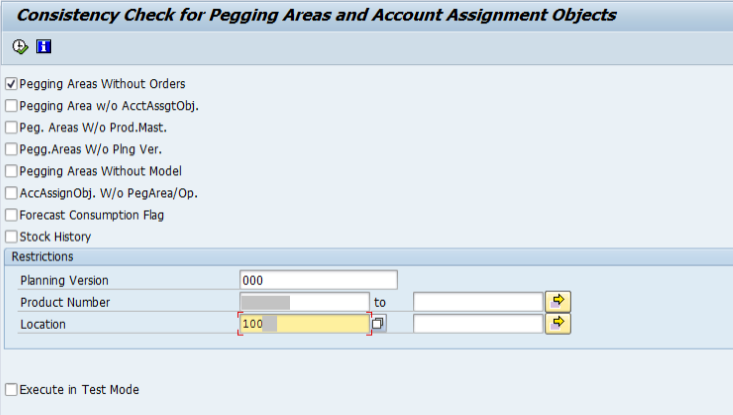

Executing the program brings the screen to this selection screen:

The initial fields are for different types of inconsistencies as discussed in previous section.

The “Restrictions” fields are for restricting the action for the desired set of product/location/production version combination.

An option of “Execute in Test Mode” is given so that we could review which pegging areas are selected by the program, before making a decision on deleting those.

Now we shall go through a test case where we shall do the cleanup. Before pegging areas cleanup, there are 89 pegging areas (t-code /SAPAPO/RRP_NETCH):

MRP Heuristics Run found 89 pegging areas during the stage numbering algorithm step (to calculate low level code for the products)

Cleanup of obsolete pegging areas:

It deleted 39 pegging areas:

Since it deleted 39 out of 89 planning files (pegging areas), the count should become 50 (89-39) now.

Re-checking planning files (t-code: /SAPAPO/RRP_NETCH):

The pegging areas count is now 50:

Running MRP and detailed scheduling jobs:

Checking Planning Logs:

This time, the stage numbering algorithm step found pegging areas to be planned as “50” (updated figure); thereby indicating the success of cleanup of obsolete pegging areas.

Conclusion:

Benefit of removing inconsistent / obsolete pegging areas:

The important benefit of removing or cleaning up of inconsistent pegging areas is that it improves system performance.

SAP recommends scheduling of this standard program /SAPAPO/DM_PEGKEY_REORG on a periodic basis.

References

Based on work experience and SAP Help.

All images used in the document are taken by author Kr. Rahul from SAP SCM 7.0

- SAP Managed Tags:

- SAP Advanced Planning and Optimization

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

3 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- Keep sequence at operation level (e-PPDS S4-2022) in Supply Chain Management Q&A

- Dynamic Pegging is not considering Stock and Production proccess orders - SAP APO PPDS in Supply Chain Management Q&A

- missing pegging areas in ePPDS even that we are running program /SAPAPO/PEGAREA_LC_CREATE in Supply Chain Management Q&A

- PPDS pegging sorting in Supply Chain Management Q&A

- PPDS pegging updated in Supply Chain Management Q&A

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |