- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Basics of MRP Area

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

The purpose of this document is to explain the basics of MRP area, steps involved in activating MRP area and to use it in different possible ways.

As we know MRP runs at plant level (centralized), but as per business need we may have to plan MRP for individual & independent planning areas (decentralized). This can be achieved by activating MRP areas. These MRP areas are fully configurable organizational units within ECC where MRP can be run individually. So we can broadly classify running MRP in 2 major ways.

- MRP at plant level: The system adds together stocks from all of the individual storage locations to determine total plant stock. The requirements are combined in the planning run and procurement elements are created for these pegged requirements with unknown sources. Individual storage locations can be planned separately or be excluded from planning.

Illustration:

- MRP area level: Only the stocks from the storage locations or subcontractor assigned to the respective MRP area are taken into account. The requirements in this particular MRP area are combined and procurement elements are created for them. This enables us to plan material requirements specifically for certain areas (MRP areas).

Illustration:

You can define MRP areas within a plant and carry out MRP specifically for that particular area, for example in above illustration, for MRP area M0001 can be planned independently without running MRP for plant FP01.

In each MRP area you can control staging and procurement of parts that are produced in house or externally. All MRP procedures are supported by MRP areas and one can display the result of MRP run for each MRP area.

MRP Area (definition):

As per SAP, “MRP Area represents an organizational unit for which material requirements planning is carried out independently”

MRP Area is functionality for special planning process that enables you to carry out planning not only at plant level but also at different planning levels (eg, storage location & sub-contractors). There are 3 types of MRP areas in SAP

- Plant MRP Area

- MRP Areas for storage location

- MRP Areas for Subcontractors

Plant MRP area:

MRP area can be created at plant level. On doing so, system combines all its storage locations and stock with subcontractors under that MRP area. When you define MRP areas for storage locations and for subcontractors and assign material to newly created MRP areas with in plant then the plant MRP area gets reduced by exactly the numbers of subcontractors and storage locations. This is because they will now be planned separately in new MRP areas.

MRP area for storage location:

MRP area can also be defined for storage location or multiple storage locations. Material requirements for this storage location are then planned separately from the rest of the plant. Important point to note here is that you can assign 1 storage location to only 1 MRP area but you can have multiple storage locations under single MRP area. It’s a N to 1 relationship.

MRP Areas for Subcontractors:

You can also define an MRP area for each subcontractor. Important point to note here is that a subcontractor can be assigned to only one MRP area in a plant. An MRP area of the subcontractor type can only contain one subcontractor. It’s a 1 to 1 relationship.

How to setup MRP area in SAP

There are 2 aspects of setting up MRP area. First one is to activate it in customizing and second part it to set up master data (i.e. adding materials to that particular MRP area in material master).

MRP with MRP area is not operational until you assign MRP area to a particular material in material master or in order words create a MRP area segment. If you have not assigned a material to an MRP area, that is, you have not created an MRP area segment in the material master, the material will continue to be planned in the plant MRP area only.

Step 1 - Converting Planning file entries

Path: SPRO > Production > Material Requirement Planning > Master Data > MRP Areas > Convert Planning file entries for MRP areas – OM0F or SE38 program RMDBVM00

When we convert planning file entries for MRP area, system creates plant MRP area for each plant. Following entries from below tables are converted. Planning file entries are maintained in MRP file which are converted to MRP area file in below tables.

Planning file entries in MDVM are converted to DBVM

Planning file entries in MDVL are converted to DBVL

Planning file entries in KDVM are converted to KBVM

Planning file entries in KDVL are converted to KBVL

If you are running converting planning files for the first time then system will automatically create plant MRP areas. These new entries can be seen in OMIZ under plant MRP area with area type "01".

IMP note: After the conversion, contents of MDVM/MDVL/ KDVM/KDVL are deleted and entries are created in DBVM/ DBVL/ KBVM/ KBVL.

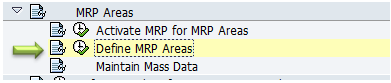

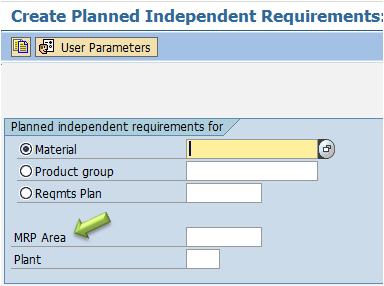

Step 2 - Define MRP area in SPRO - OMIZ

Path: SPRO > Production > Material Requirement Planning > Master Data > MRP Areas > Define MRP areas

MRP area has 3 types (01, 02 & 03) and system will allow you to have MRP areas in below types only (Plant, Storage location or Sub Contractor)

Plant MRP area should have same name as plant so you can have only one entry for plant MRP area. For example plant 1000 will have plant MRP area as 1000.

In order to maintain consistency and uniformity, only MRP areas of the type 'plant' are allowed to have 1-4 digits key. Sloc MRP area should have minimum of 5 digits. Example M0001 etc…

You can only have 1 sub-contractor vendor assigned to 1 MRP area. Multiple vendors cannot be grouped together in a single MRP area.

You can have multiple storage locations combined together in a single MRP area.

You can only one entry for plant in plant MRP area. Multiple plants cannot be grouped together in a single MRP area.

Once MRP area is defined, next step is to Activate MTP area

Step 3 - Activating MRP Areas – OM01

Path: SPRO > Production > Material Requirement Planning > Master Data > MRP Areas > Activate MRP for MRP areas

NOTE: MRP areas are activated at client level. Once you activate it, it will be available for all plants and MRP areas features would be available to use.

This sums up setting up MRP area configuration in SAP customizing.

You can find following changes due to activation of MRP area. These are just few for example

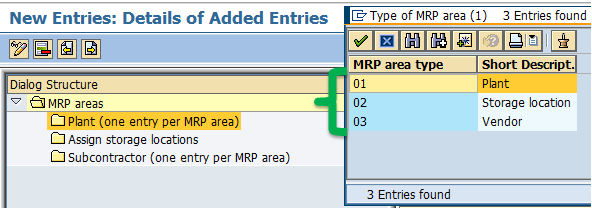

MD61 – PlR creation

MRP

Material Master

Stock Requirement list

Step 4: Master data for MRP area

The material will not be considered in MRP area planning until it’s extended to MRP area. Following steps shows how to extend a material in MRP area. You can extend a material to multiple MRP areas based on the need.

Go to change material master under MRP 1 screen and assign MRP area as shown below:

You will have additional views for MRP 1, MRP 2, Forecast & Consumption values. You need to fill required fields as per your need.

When you assign a material to a new MRP area, a new record for this assignment gets added in the planning file. You have an option to define individual MRP and forecast parameters for each MRP area that you assign to a material. These parameters can differ from those defined in the material master at plant level. As an example, you can have different MRP controllers, lot size or MRP type for each individual MRP areas that is assigned to a material.

Users can set up different forecast model and consumption values in MAR area tabs. Once MRP with MRP area is activated, ATP check is also activated at MRP area level.

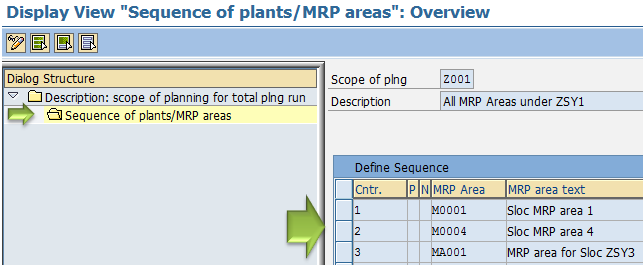

Scope of planning with MRP area

You can create scope of planning run if you want to carry out total planning for limited MRP areas. In case you do not give any MRP area in total planning run, system will consider all MRP areas under a plant and plan for them in total planning.

For single item planning system, in MD02 & MD03 system plans a material only in the specified MRP area.

Sample Scenario:

Let’s consider a material Assembly maintained in plant ZSY1 under 2 storage locations (ZSY3 & ZSY4)

Sloc ZSY3 maintained in MRP area MA001. Assembly is extended to MA001 with following stock situation

ZSY3 – 100 (under storage location MRP area MA001)

ZSY4 – 150 (under Plant MRP area ZSY1)

Lot size for same material is maintained as FX (fixed lot size) in MA001 MRP area and EX in plant MRP area ZSY1

Total stock MMBE

MD04 - MRP Area ZSY1

MD04 - MRP Area MA001

Let’s have requirement from a Sales order for plant ZSY1, it will come under plant MRP area ZSY1

For testing, we can also have PIR created for specific MRP area MA001

Here is the stock situation of MD04 with sales order in Plant MRP area

Stock requirement for MRP area MA001:

If we run MD02 for plant ZSY1, system will only consider plant MRP area and will not plan for MRP area MA001 as it’s a separate planning area

MRP area MA001 is untouched:

After running MRP for MA001 system creates planned order for 200 quantities

Material Assembly was maintained as EX lot size in plant MRP area and with fixed lot size 200 in MA001 hence planned order of 200 Qty created in MA001. In this way separate planning parameters can be maintained to run requirement planning using MRP areas.

~~~~~~~~~~~~~~~

Thank you for reading this document. Please feel free to suggest any change and modification needed to improve the document.

*Scenarios related to MRP areas will be covered in a separate document. The link will be added below once completed

- SAP Managed Tags:

- MAN Production Planning (PP)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Improvements to manage treasury position in SAP Treasury and Risk Management in Enterprise Resource Planning Blogs by SAP

- valuation area not defined what should i Do for it in Enterprise Resource Planning Q&A

- Valuation area not definedMessage No. ME059 in Enterprise Resource Planning Q&A

- JOB in SAP S/4HANA Public Cloud to update Custom Business Object in Enterprise Resource Planning Q&A

- OKB9 problem: message no. KI235 in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 6 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |