- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Outsourced Manufacturing - Classic Subcontracting

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Overview

Enhancement of conventional subcontracting business process in to modern method through SAP enhanced and future.

Highlight

- Powerful,Improved version of conventional subcontracting method, Highly monitored,visibility towards subcontracting

- More collaborative business process (In case of SNC Integration)

- Easy to Use, One touch Solution for many processes

- Highly interlinked and reduced manual effort

- Increased efficiency in purchasing administration

- Productivity improved

- Reduction of process complexity

Scope of Outsourcing

- Create Subcontracting Purchase order

- Purchase order process with Serial number (In case of Equipment Repair)

- Outbound delivery of subcontracting components via Subcontracting Cockpit

- Goods issue for delivery and shipment to subcontractor (Stock-in-Transfer)

- Shipping notification (ASN) from Subcontractor for Main material as well as Components

- Goods receipt for purchase order delivered by subcontractor (Through Inbound delivery method)

- Component reservations and consumption of component quantities as provision of material

- Component consumption history

- Scrap analysis

- SNC Integration

Outsourcing Data Flows

Functionality Improvement

- Serial number assignment in Subcontracting Purchase order (In case of Serial profile active)

- Subcontracting Cockpit

- New Movements

- Subcontracting Components (BOM) in Inbound delivery (IBD)

- Consumption history

- Scrap Report

- Monitoring component consumption, Batch tracing, Transfer of AMPL (In case of SNC Integration)

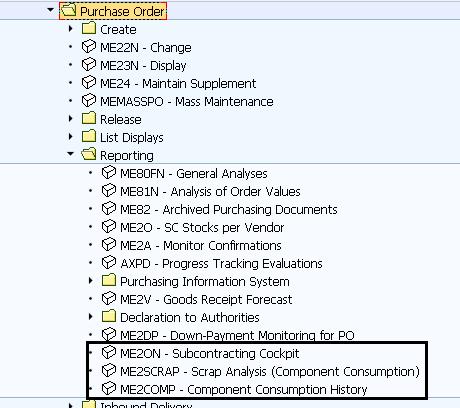

1. Subcontracting Cockpit

The subcontracting cockpit is simple to use and control the overall subcontracting process. It gives high visibility towards subcontracting process.

The advantages of Subcontracting cockpit are as under:-

- ALV Grid based

- Monitoring subcontracting stock

- Facility to change the shipping point and batch number when the outbound delivery is getting created

- Visibility in Subcontracting purchase order, PP orders, STO and deliveries

New movement types available to make one step/two step stock transfer to Vendor (Example, Movement type 30A & 30C: Transfer of unrestricted-use

stock to subcontracting stock in two steps # stock removal)

- Stock position indicator at subcontractor's end (positiv or negative)

- Individual delivery can be created for each component

- The output report can be downloaded and the list can be sent via email

Transaction: ME2ON

Goods issue to subcontractor "outbound delivery" will appear in the purchase order history overview. Hence, it is useful for the SCM team to check whether the particular SC order components have been issued or not by navigating further.

2. Serial Number Assignment

Serial number can be assigned when the subcontracting Purchase Requisition/Purchase Order is getting created.

When you send the equipment for repair, there is no need of input serial number again.

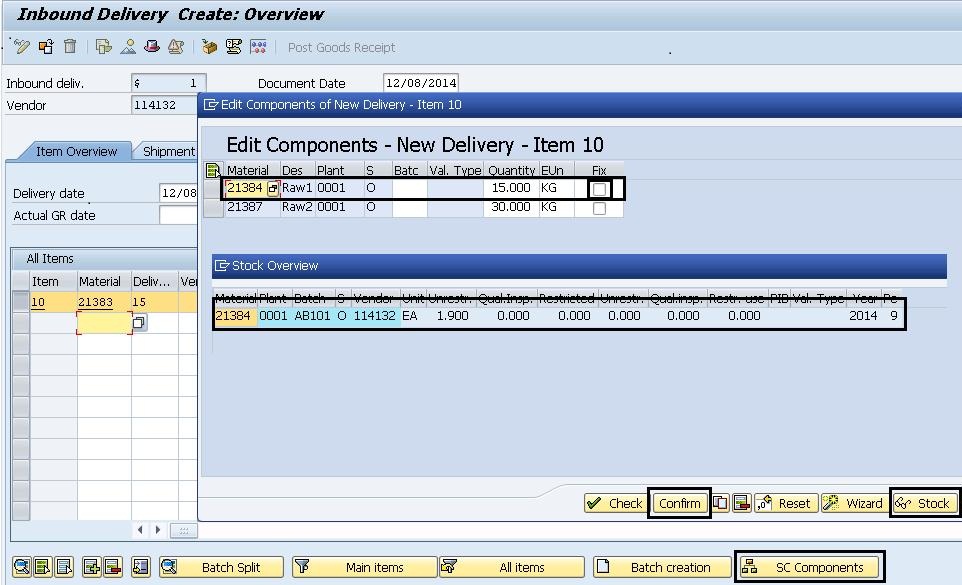

3. Inbound Delivery Creation with Subcontracting Components

The subcontracting components (BOM) can be entered when the Inbound delivery is getting created. This functionality allows to assign subcontracting materials and its batches including quantities in Inbound delivery screen.

- Subcontracting components can be entered

- Assignment of subcontracting material quantities and batches from the stock overview in Inbound delivery creation screen itself

- Posting Goods receipt from the same screen without entering batches again

- Manual batch entry completely removed

- Productivity can be improved because of absence of batch manual entry

- Improves batch tracking from Sourcing to Sell in case of SNC integration

4. Stock Transfer (One Step & Two Step) and Monitoring

The new movement types are introduced to monitor subcontracting stock and consignment stock in a more effective way.

- Track subcontracting components in transit as well as at subcontractor’s end

- Transfer stock from supplying plant to subcontractor directly in one step in case of STO

- Process can be completed in single step

- Multiple posting reduced

The Purchase order is getting created. Assign the subcontracting vendor as a recipien. In case of two step procedure, use "30A" mvoement type to issue the components from the supplying plant.

Once the component issued from the supplying plant, it will come to the SC in transit. The same can be monitored under stocks at Subcontractor.

The document will be updated in outbound delivery document flow

Finally, do the Place in storge with reference to the goods issue document reference. The stock will be moved to subcontractor's unrestricted area.

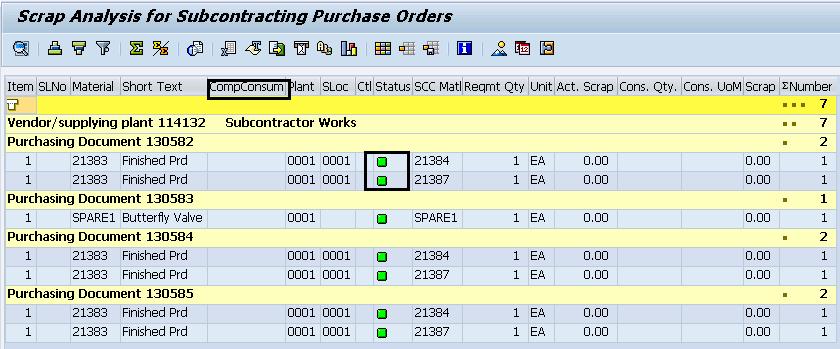

5. Component Consumption and Scrap Analysis

The component consumption and scrap report will give high visibility on consumption and scrap out of subcontractor work

- Scrap report indicates whether the scrap is under control or not

- Scrap report provides average scrap for a specific vendor

- Component consumption report provides consumption of components for a specific purchase order and will be automatically update in case of SNC

integration

- The purchase order history can be navigated from this report and further drilldown of consumed components also possible

6. SNC Integration

With SNC integration, supplier can plan replenishment and subcontracting. The confirmation of work in SNC, key information is sent automatically to SAP.

- Component consumption can be booked automatically in a timely manner

- Monitoring of component consumption exactly

- The vendor can monitor the shipped component from Customer

- Timely consumption enables to book the consumption of subcontracting components separate from the goods entry

- Batch tracking

For the subcontracting info record, select "RT consumption" in Purchase organization data view. In case, SNC integration, ECC will be updated with the real time component consumption at subcontractor's end. The consumptions of the subcontractor are displayed in the component consumption history.

Key Business funtion

To achieve the above functionalities, one needs to activate the following business function and subsequent configuration settings in SAP ECC.

Main business function: LOG_MM_OM_1 (Outsourced Manufacturing - Part1)

for Serial number, LOG_MM_SERNO (Serial Numbers in Purchasing with Integration in Inventory Management & Shipping)

Prerequsite:

Business_Function_Basis_Com (Business Function Basis (COM))

Minimum Software Requirement:

SAP ECC 6.0 EhP4

Configuration Settings:

Define Item Category Determination in Deliveries:

Menu Path:

| SPRO--->Logistics Execution--->Shipping--->Deliveries--->Define Item Category Determination in Deliveries |

Here, create a new combination of delivery type and item category for the subcontracting delivery type (LB) with usage as "V".

Define Document types for Purchase Requisition:

Menu Path:

SPRO--->Materials Management--->Purchasing--->Purchase Requisition--->Define Document Types |

Here, assign the serial number profile to the Purchase requisition document type. The same profile should be assigned to the serial number procedure "PRSL".

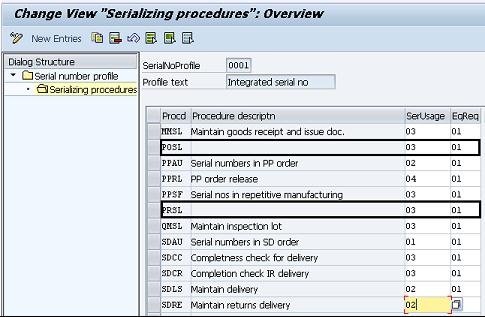

Determine Serial Number Profiles

Menu Path:

| SPRO--->Materials Management--->Purchasing--->Serial Numbers--->Determine Serial Number Profiles |

Here, create a serial number new procedure "POSL" and "PRSL" for purchase order and purchase requisition respectively and assign the same to serial profile.

Define Document Types for Purchase Order:

Menu Path:

| SPRO--->Materials Management--->Purchasing--->Purchase Order--->Define Document Typess |

Here, assign the serial number profile to the Purchase requisition document type. The same profile should be assigned to the serial number procedure "POSL".

Set Up Subcontract Order:

Menu Path:

| SPRO--->Materials Management--->Purchasing--->Purchase Order--->Set Up Subcontract Order |

Supplying plant needs to be assigned to the subcontracting delivery type "ZL"

Default Document Type for Stock Transport Orders:

Menu Path:

| SPRO--->Materials Management--->Purchasing--->Purchase Order--->Set up Stock Transport Order--->Assign Document Type, One-Step Procedure,Underdelivery Tolerance |

Here, maintain document type for the supply plant and receiving plant combination with one step or two step procedure. In case of one step procedure, the stock will be directly go to subcontractor's stock without going to the receiving plant.

Setting for Field Seletion group for SNC Integration:

Menu Path:

| SPRO--->Materials Management--->Purchasing--->Purchasing Info record--->Define Screen Layout--->Screen layout – Info record |

In case of SNC integration, to update real time component consumption in ECC, teh field timely consumption needs to be activated. The below screenshot shows the activation of the field "Timely consumption" in info record.

Conclusion

With this new functionalities, Industries can leverage this process for consistent and more collaborative business purpose.

Author Bio

Mohamed Hasan Rifaie, a SAP Certified Procurement consultant, is now an employee of Larsen & Toubro Infotech Ltd. He has overall 13+ years of experience, out of which 7+ years in SAP Consulting (P2P, SRM, SCM & WM). He has business experience in various industries like Manufacturing, Electro mechanical Construction and Process industries as a Procurement Executive.

- SAP Managed Tags:

- MAN (Manufacturing),

- MM (Materials Management)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Supply Chain Management in SAP S/4HANA Cloud, Private Edition 2023 in Enterprise Resource Planning Blogs by SAP

- Third party subcontracting in Enterprise Resource Planning Q&A

- Subcontracting PO with Alternative component BOM explosion in SAP S/4HANA Cloud, Public Edition in Enterprise Resource Planning Blogs by SAP

- Create Production Order with Subcontract Operation in SAP CLOUD Public edition in Enterprise Resource Planning Blogs by Members

- SAP Material Management Procure-to-Pay Process in Enterprise Resource Planning Blogs by Members

| User | Count |

|---|---|

| 6 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |