- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by Members

- Managing Buffer Interface in SAP F&R Landscape

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Abstract:

SAP SCM F&R system deals with very high volume of master and transaction data due to the nature of business in Retail sector and no of stores and SKUs involved in planning process. Due to the huge volume of data, interface between F&R and ECC is designed differently as compared to Core Interface (used between APO and ECC). Data interchange between F&R and ECC takes place through the interface named as “Buffer Interface”. This paper attempts to capture the technical architecture of buffer interface and discuss the consistency reports that need to be executed periodically to keep both the systems in sync and ensure higher level of accuracy of the planning results generated from the FRP run.

1.0 Introduction to F&R

SAP Forecasting and Replenishment (SAP F&R) is a Retail specific application out of the SAP for Retail portfolio. A standard integration into Retail’s powerful back office system comes as part of the solution and massive amounts of data are being transferred almost on a daily basis. The challenge to feed SAP F&R with large amounts of master data and master data changes as well as transactional information via a set of highly of complex interfaces requires tools and monitors in order to ensure data consistency at all times in all areas as early as possible.

Data inconsistencies will negatively impact the results in all subsequent F&R processes such as forecast calculation by using for instance incorrect information on sources of supply, minimum stock, procurement cycles, listing intervals and eventually end up in critical stock-out or stock-over situations.

Manual checks and controls are not an option in high-volume Retail businesses so a set of check reports and monitoring tools is available to compare master data on both sides – ERP and SAP F&R – and display any inconsistency to allow early intervention and prevent damage in the follow-on processes.

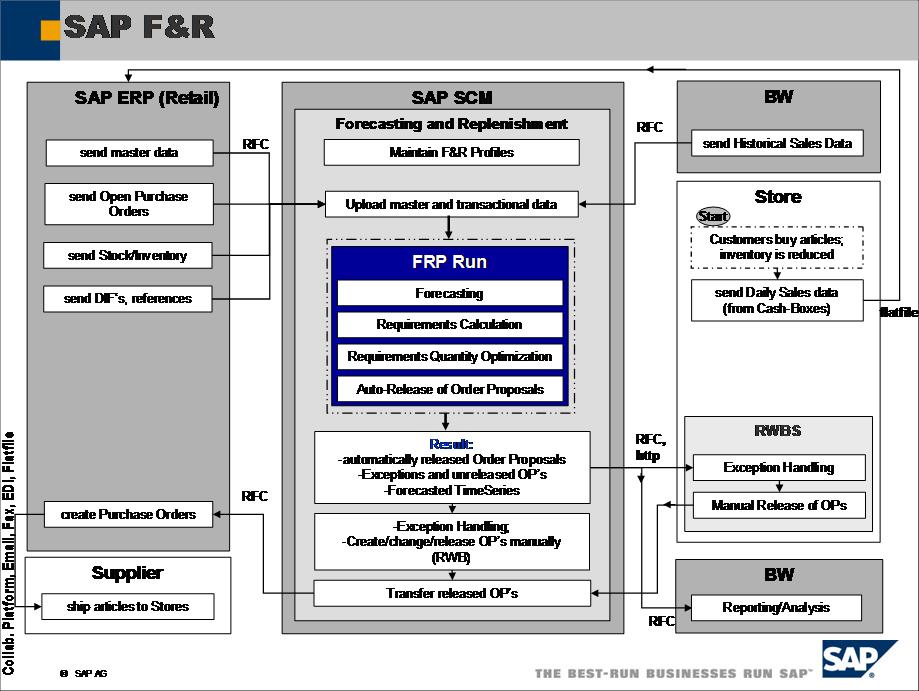

2.0 F&R Architecture

Business Process Description:

This business process description will describe only the most important steps that are necessary to operate an SAP F&R solution. Individual SAP F&R implementations of customers are not considered. Therefore, it can be that individual critical steps are not described, or that some steps in this description are not relevant for specific customers.

Master Data Load:

The master data is sent via RFC to SAP F&R using the standard SAP ERP Retail Plug-In Interface.

Transactional Data Load:

Open and changed orders in SAP ERP Retail and Stock/Inventory data are sent to SAP F&R via RFC using the standard SAP ERP Retail Plug-In Interface.

(SAP F&R Architecture)

For master data of new SAP F&R relevant article/site combinations there is an initial load (report FRE_INIT_LOAD, transaction FRE01) first from SAP ERP Retail to SAP F&R. This report is supposed to be started once for the initial data supply of SAP F&R. Then, the delta load (report FRE_DELTA_LOAD, transaction FRE02) for change pointers due to master data changes by planners is executed daily.

3.0 Architecture of Buffer Interface

Buffer interface is the interface through which the master and transaction data get transferred from ECC to F&R and vice-versa through RFC. Unlike Core Interface (CIF) used in SAP APO, Buffer Interface (BIF) is asynchronous and is designed to handle high volume of data involved in retail planning process.

Technical architecture of the buffer interface is as shown below:

In Buffer Interface, data gets pushed from ECC to buffer tables in the interface and from the buffer tables, booking job transfers the data to F&R. Order proposals created by F&R are transferred to ECC using a SAP standard program. Data between the two systems are in sync only at a point of time and any changes in ECC are not automatically reflected into F&R until the consistency programs are executed through the buffer interface.

4.0 Consistency Reports in ECC

SAP provides the following reports to maintain consistency between ECC and F&R systems. These reports are executed in SAP ERP system.

4.1 FRE_CHECK_LOC_PROD (T Code – FRE_C1)

Report compares location product master data and optional sales price, listing information, reference modules and unit of measure between SAP ERP Retail and SAP F&R and displays inconsistencies like missing location product data in SAP F&R or SAP ERP Retail as well as differing location product master data field values.

In a first step on the SAP ERP Retail side, the relevant article/site combinations that exist in table FRE_DB_ART_SITE are read according to the selected site and article. The required data from SAP F&R is collected via remote function call using FM /FRE/MD_CHK_READ_DATA. Then, the required data is selected from the SAP ERP Retail side using FM FRE_MD_CHK_READ_DATA.

In a following step, the collected master data values from SAP ERP Retail and SAP F&R are compared.

Detected inconsistencies can be cleaned up executing the report FRE_REINIT_LOAD for inconsistent location products in ECC. Afterwards, in F&R, run report /FRE/BIF_INB01 for location products to post the entries from buffer table to F&R database.

4.2 FRE_CHECK_LAYOUT_MOD (T Code – FRE_C3)

The report FRE_CHECK_ LAYOUT_MOD compares layout module data between SAP ERP Retail and SAP F&R and displays found inconsistencies like missing layout module data in SAP F&R or SAP ERP Retail as well as deviations in layout module data field values.

In a first step, on the SAP ERP Retail side the relevant article/site combinations existing in FRE_DB_ART_SITE are read according to the selected article and site. The required data from SAP F&R is collected via remote function call. Then, the required data is selected from the SAP ERP Retail side. In a following step, the report searches for inconsistencies by comparing the layout module data between SAP ERP Retail and SAP F&R.

Detected inconsistencies can be cleaned up executing the report FRE_REINIT_LOAD in ECC followed by the execution of the report /FRE/BIF_INB01 in F&R to post the entries from buffer table to F&R database.

4.3 FRE_CHECK_SUPPLY_NET (T Code – FRE_C2)

The report FRE_CHECK_SUPPLY_NET compares supply net data (internal and external transportation lanes) between SAP ERP Retail and SAP F&R and displays found inconsistencies like missing transportation lanes in SAP F&R or SAP ERP Retail as well as deviations in supply net data field values.

Depending on the SAP F&R release, the supply network consists of different tables. The report considers if the old lanes model or the new lanes model is active (table FRE_SEND_OPTION, field FRE_NEW_LANES).

In a first step on the SAP ERP Retail side, the relevant article/site combinations that exist in FRE_DB_ART_SITE are selected according to the selected article and site.

The required supply net data is collected from SAP F&R via remote function call. Then, the required supply net data is determined on SAP ERP Retail side. In a following step, the collected supply net data from SAP ERP Retail and SAP F&R is compared.

Detected inconsistencies can be cleaned up executing the report FRE_REINIT_LOAD followed by the execution of report /FRE/BIF_INB01 in F&R to post entries from buffer table to F&R database.

4.4 FRE_CHECK_PO_OP (T Code – FRE_C4)

The report FRE_CHECK_PO_OP compares purchase order and order proposals between SAP ERP Retail and SAP F&R and displays found inconsistencies like missing order proposals / missing purchase orders in SAP F&R or SAP ERP Retail as well as differing data field values.

In a first step on the SAP ERP Retail side the selected data will be checked for relevancy. The relevant article/site combinations that exist in table FRE_DB_ART_SITE are read according to the selected site and / or article. In a second step it will be checked if purchase orders exist which are relevant for transmission to SAP F&R via checking the relevant document types according to customizing and several criteria regarding the order itself (such as LOEKZ etc.). Then it will be checked if order proposals exist which are relevant for transmission to SAP ERP.

Only order proposals which have at least status transferred (31) and at the most status completed (90) are compared for consistency. In a following step, the collected purchase orders and order proposals from SAP ERP Retail and SAP F&R are compared.

Detected inconsistencies can be cleaned up executing report FRE_ORD_START_OUTB_INTVL in ECC for inconsistent purchase orders. Afterwards, in F&R, run report /FRE/BIF_INB01 to post the entries from buffer table to F&R database.

4.5 FRE_REORG_ART_SITE (T Code – FRE_C5)

While an article site combination is transferred to SAP F&R for the first time, an entry in a control table (FRE_DB_ART_SITE) is created in order to indicate that the initial load of all relevant data for that article site combination to SAP F&R has been carried out.

In case an article site combination is not relevant for SAP F&R anymore, the entry in the control table FRE_DB_ART_SITE is removed (FRE02). In case a specific site is not relevant for SAP F&R anymore because it is not contained in any SAP F&R relevant article site combination anymore, it should also be removed from FRE_DB_SITE.

5.0 Consistency Reports in F&R

This section describes the consistency reports those can be executed in SAP SCM F&R system.

5.1 /FRE/BIF_CHECK_CONSUMPTION (T Code – /FRE/BIF_CHECK_CONS)

Report /FRE/BIF_CHECK_CONSUMPTION compares consumption data based in SAP ERP or SAP BI with consumption data in SAP F&R. Using this report it is possible to select the data base in SAP ERP to be compared with the data in SAP F&R.

Consumption data stored on weekly and daily basis can be compared. In case the report detects inconsistencies it will be displayed by naming the system with the data inconsistency and also the period (time bucket).

In a first step in SAP F&R the location products to be checked in SAP ERP are selected and then depending on the selection criteria table MSEG or MVER will be accessed via remote function call in order to perform the check.

Detected inconsistencies can be cleaned up for the data source in ERP by executing the report FRE_SEND_TSD (T Code – FRE03). This report transfers the consumption data to F&R buffer table /FRE/BIF_TSD.

To start the interface processing in F&R to book the data from buffer tables to F&R database, within the interface processing transaction the flag “time series data” has to be set and execute the report: /FRE/BIF_INB01 (T Code - /FRE/BIF).

5.2 /FRE/BIF_CHECK_STOCK (T Code – /FRE/BIF_CHECK_STOCK)

A state in which the consumptions of both systems can be compared can only be reached once the interface processing in both involved systems has successfully finished. This means in SAP ERP the Report interface “FRE_SEND_TSD” (transaction FRE03 – transfer of stock and consumption data) was executed and no changes to the stock have occurred since then. In SAP F&R the report “/FRE/BIF_INB01” (inbound processing of stock data) was executed and has finished successfully.

Report /FRE/BIF_CHECK_STOCK generate the list of inconsistencies between ERP and F&R which needs to be corrected using SAP ERP time series interface for stock information. To remove inconsistencies, use report FRE_SEND_TSD in ECC. This report transfers the consumption data to F&R buffer table /FRE/BIF_TSD. Subsequently, execute report /FRE/BIF_INB01 in F&R.

6.0 Lessons Learned

- Execution of Inconsistency Jobs are performance Intensive - Inconsistency jobs in F&R landscape are highly performance sensitive due to huge volume of data compared and multiple interfaces involved. SAP recommended OSS notes must be implemented to address all the performance issues. Additionally, to manage the execution of the consistency reports, jobs need to be staggered in different time periods throughout the week when stores are not operating or least amount of transactions are being entered into the ERP system. After generating the inconsistencies, they need to be fixed using cleanup reports manually which needs to be scheduled to avoid any performance issues in SAP ECC.

- Inconsistencies of data impacts FRP Run - Master and transaction data inconsistencies impact the duration of FRP (Forecasting & Replenishment Planning) run resulting in delayed completion of the planning jobs. Data inconsistency also results in failure of planning run for stores for which the data is incorrect. Any batch job failure needs to be addressed manually and demands extensive man-hours from application support team.

- Data Consistency requires on-going maintenance - To have explainable planning output from FRP run, data consistency must be planned carefully and dedicated team should be put into place to improve and maintain the quality of data. Continuous support required to clear the data stuck in the interface after every FRP run and order proposals released from F&R to ECC. Otherwise, duplicate or delayed procurement might disrupt the inventory levels since retail stores operate on optimized inventory and procure more frequently to reduce the cost of storage and obsolescence. Any delay in clearing the order proposals from interface might result in a new order proposal from FRP run the following day, resulting in duplicate orders.

7.0 Conclusion

Data inconsistencies play a crucial role in F&R landscape. Unlike CIF in APO, where the transaction data are transferred from ECC to APO in real-time, buffer interface in F&R is asynchronous. Any synchronization between ECC and F&R is an on-going maintenance activity and needs to be ensured before every FRP run.

Presence of buffer interface (BIF) facilitates the handling of high volume of data, but poses challenge of asynchronous data transfer unlike CIF. BIF can handle huge volume of data whereas CIF is designed for only critical data relevant for advanced planning in APO. Managing integration in CIF is easier due to one time configuration and activation of integration models, following which transaction data flows in real-time and master data needs to be synchronized less frequently after initial transfer. Managing integration using BIF is challenging due to asynchronous mode of data transfer through buffer tables.

While planning the data management strategy, planners must consider the performance issues due to data volume and schedule of the jobs to generate inconsistencies and their manual cleanup.

8.0 About the Author:

Pravat Dash, CPIM is a Managing Consultant in the Business Consulting Services Group of IBM Global Services. He has over 16 years of SAP SCM/ERP implementation and industry experience in the area of Supply Chain Management and Logistics. He has worked as Lead Consultant and APO Team Lead for implementing SAP SCM solutions for clients in various industry verticals for the past 12 years. He has authored multiple papers in Supply Chain Planning space. You may reach him via email prabhatdash2003@yahoo.co.in.

- SAP Managed Tags:

- SAP Supply Chain Management

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

aATP

1 -

ABAP Programming

1 -

Activate Credit Management Basic Steps

1 -

Adverse media monitoring

1 -

Alerts

1 -

Ausnahmehandling

1 -

bank statements

1 -

Bin Sorting sequence deletion

1 -

Bin Sorting upload

1 -

BP NUMBER RANGE

1 -

Brazil

1 -

Business partner creation failed for organizational unit

1 -

Business Technology Platform

1 -

Central Purchasing

1 -

Charge Calculation

2 -

Cloud Extensibility

1 -

Compliance

1 -

Controlling

1 -

Controlling Area

1 -

Data Enrichment

1 -

DIGITAL MANUFACTURING

1 -

digital transformation

1 -

Dimensional Weight

1 -

Direct Outbound Delivery

1 -

E-Mail

1 -

ETA

1 -

EWM

6 -

EWM - Delivery Processing

2 -

EWM - Goods Movement

4 -

EWM Outbound configuration

1 -

EWM-RF

1 -

EWM-TM-Integration

1 -

Extended Warehouse Management (EWM)

3 -

Extended Warehouse Management(EWM)

7 -

Finance

1 -

Freight Settlement

1 -

Geo-coordinates

1 -

Geo-routing

1 -

Geocoding

1 -

Geographic Information System

1 -

GIS

1 -

Goods Issue

2 -

GTT

2 -

IBP inventory optimization

1 -

inbound delivery printing

1 -

Incoterm

1 -

Innovation

1 -

Inspection lot

1 -

intraday

1 -

Introduction

1 -

Inventory Management

1 -

Localization

1 -

Logistics Optimization

1 -

Map Integration

1 -

Material Management

1 -

Materials Management

1 -

MFS

1 -

Outbound with LOSC and POSC

1 -

Packaging

1 -

PPF

1 -

PPOCE

1 -

PPOME

1 -

print profile

1 -

Process Controllers

1 -

Production process

1 -

QM

1 -

QM in procurement

1 -

Real-time Geopositioning

1 -

Risk management

1 -

S4 HANA

1 -

S4-FSCM-Custom Credit Check Rule and Custom Credit Check Step

1 -

S4SCSD

1 -

Sales and Distribution

1 -

SAP DMC

1 -

SAP ERP

1 -

SAP Extended Warehouse Management

2 -

SAP Hana Spatial Services

1 -

SAP IBP IO

1 -

SAP MM

1 -

sap production planning

1 -

SAP QM

1 -

SAP REM

1 -

SAP repetiative

1 -

SAP S4HANA

1 -

SAP Transportation Management

2 -

SAP Variant configuration (LO-VC)

1 -

SD (Sales and Distribution)

1 -

Source inspection

1 -

Storage bin Capacity

1 -

Supply Chain

1 -

Supply Chain Disruption

1 -

Supply Chain for Secondary Distribution

1 -

Technology Updates

1 -

TMS

1 -

Transportation Cockpit

1 -

Transportation Management

2 -

Visibility

2 -

warehouse door

1 -

WOCR

1

- AI-powered supply chain solutions: Better decisions, better outcomes in Supply Chain Management Blogs by SAP

- Retail: physical inventory with MDE in Supply Chain Management Q&A

- RISE with SAP Advanced Logistics Package in Supply Chain Management Blogs by SAP

- SAP Transportation Management in SAP S/4HANA 2023 FPS01, Private Cloud is here! in Supply Chain Management Blogs by SAP

- Integrating SAP Datasphere with SAP Integrated Business Planning, using SAP CI - Part 2 in Supply Chain Management Blogs by SAP

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |