- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Order fulfillment for complete delivery scenario

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Order fulfillment for ship complete scenario

Overview:

There are many ways of order fulfillment and most of them are based on how the material is classified ie Make to stock, Make to order etc.

1. Make to Stock Order fulfillment

Here the stock is readily available based on the forecast and mostly stored in Centralized warehouse for quick response to customers demand.

2. Make to Order or Configure to order fulfillment

In make to order scenarios the product ordered by the customer is a customized one and hence is build only when the order is inducted in the system

These orders are not fulfilled from warehouse rather those order go to plant where these products are build as per customers requirement and then shipped out

3. There are certain scenarios where customer demand both Make to order and Make to Stock product in a single order and they want to have both the products delivered in single shipment

So here for the make to stock line item the plant defaulted is warehouse plant (MAR1), where as for the make to stock line item the plant defaulted is plant (MAR2) .So in order to ship both the products should have same delivering plant.

Thus below we have discussed one of the method to achieve the same and configuration setup required from SD, MM & APO end

Summary of outcome from the changes done

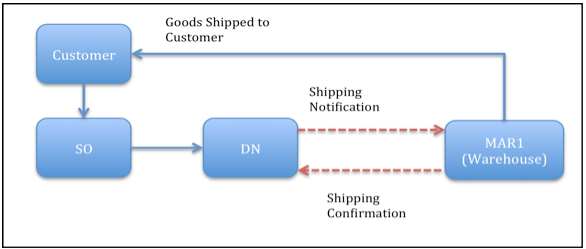

- In this scenario as soon as the complete delivery tab in SO is selected the plant for make to order based line item will be changed from MAR2 to warehouse plant MAR1 based on the multi item single location config maintained in APO

- Post this the schedule line of the order based line item will have a purchase requisition which when converted to PO is an STO to transfer the stock from MAR2 to MAR1 once the same has been build in MAR2 plant as per customers requirement.

- Once both the stock is available in warehouse plant MAR1 the DN is dropped and order is fulfilled

1. SD related Configuration Steps:

- Configure schedule line category to create STO PR in schedule lines

1.1 Creating Schedule line catergory “MA”

- Sales & Distribution-->Sales-->Sales Document-->Schedule Lines-->Define Schedule line Catergories

Key Changes:

- Item category used as ‘7’ ie Stock Tranfer

Account Assgnt Cat as ‘M’ ie Individual Customer w/o KD-CO

1.2 Assign the Schedule line category to the respective Item cat

2. APO related Configuration steps:

(To default the warehouse plant on setting the Ship completed tab)

We can use APO Rule based ATP functionality to make “Complete delivery” Sales order to point to a single plant. For this we need to use the rule type MISL (Multi Item Single Location).

Rule based ATP check is an iterative, step-by-step availability check process driven by self defined rules. The results of one step determine whether the next condition type needs to be further processed and checked.

Configuration:

2.1 The Rule Based ATP check is enabled in the Check Instruction.

The Check instruction is the combination of Check mode and business Event.

So the Check instruction for this part must have the Rule based indicator set up so that Rules are called as required.

At this point assumption is that the Condition table, Access sequence, Strategy sequence is already setup.

2.2 The MISL rule also activated in SPRO >> Advanced planning and optimization >> Global Available to promise >> Rule based Availability check >> Activate Multi – Item single delivery location.

2.3 So the Rule type to be used is defined in the APO >> Mater data >> Rule Maintenance >> Integrated Rule maintenance

Further the condition type has to be specified showing when order is marked as “Ship complete” then it should call MISL rule.

3. MM related configuration steps and Master Data Setup

3.1 Master Data Setup:

- Auto PR to PO conversion

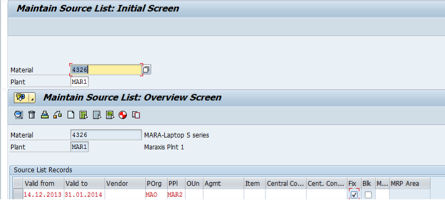

- STO Pur-Req should have the source of supply defaulted, the same will be fetched from Source list

Tcode:ME01

Note: PPL ie Procurement plant maintianed is MAR2

- Autom.PO field set in Material-Master

- Material Requirement PLanning

MRP run on plant MAR2 will create purchase requsition

- Pur-Req will have source of supply defaulted from below source list

Note:

- Vendor 233 is used for external procurement

- MRP field is set as ”1” for MRP run

End to End Cycle of above process:

Sales Order:

Select line item 20 & click on “Item Details Configuration”

STO PR:10018013

Once the STO PO is created check the Stock requirement list of the delivering plant i.e MAR1, there will be entry for SO & the corresponding STO PO

MRP RUN on Plant MAR2

Tcode:MD02

Pur-Req created.

Stock/Requirement list for Plant MAR2

Pur-Req:10018105

PR to PO conversion:

Procurement PO :1002020006

- GR against the ZCON PO:

Stock is received in Plant MAR2, Sloc MAS3 and is mapped to the SO:16089

Stock to be transferred from plant MAR2 to warehouse MAR1

Outbound Delivery against STO 4500019858

Tcode:VL10B

Movement Type : 641

The quantity is transferred unrestricted-use stock of the issuing plant to 'stock in transit' of the receiving plant.

Author:

Sivakumar Arumugham : SAP-APO

Maruti Shingade : SAP MM-Logistics

- SAP Managed Tags:

- MM (Materials Management)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Advance Return Management complete configuration(SAP ARM) in Enterprise Resource Planning Blogs by Members

- Output Type SPED trigger Inbound Delivery after PGI for Inter-Company STO's Outbound delivery in Enterprise Resource Planning Blogs by Members

- An introduction into Service Management in S/4HANA Cloud Private Edition in Enterprise Resource Planning Blogs by SAP

- Unplanned Delivery Cost of Purchasing in S4HANA Cloud, Public Edition in Enterprise Resource Planning Blogs by SAP

- How to process bulk quantity purchase order if the material is dynamic in nature. in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 6 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |