- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Real-Time Value for Manufacturing powered by SAP H...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

What better way to highlight the impact and real-time value of SAP HANA for Manufacturing than by taking MRP (Material Requirements Planning) - a process that is more than 30 years old - and completely redefining it in terms of performance and user experience. To appreciate the potential impact, you must be aware that MRP includes the 2nd most widely used group of transactions across all of ERP.

What is MRP?

In a nutshell, the purpose of MRP is to ensure that both customer and production demand are fulfilled on time by avoiding any disruptions due to missing parts or materials. MRP matches actual and forecasted demand against existing and planned supply and, by drilling-down through the bill of materials, generates an optimal plan for creating and releasing purchase and production orders. Even though the concept seems simple, having a large number of raw materials, sub-assemblies, sub-components and parts, introduces a level of significant complexity making it very difficult for a Material Planner to manage.

How is MRP performed today?

The complexity described above has an impact on the amount of time it takes to execute the MRP planning run. Reading and aggregating thousands, if not millions, of data records spread across multiple tables in the ERP system, takes a long time. Hence, the MRP planning run typically needs hours to complete and requires exclusive access to the data. It is therefore, in most cases, run outside of business hours, over the night or over the weekend.

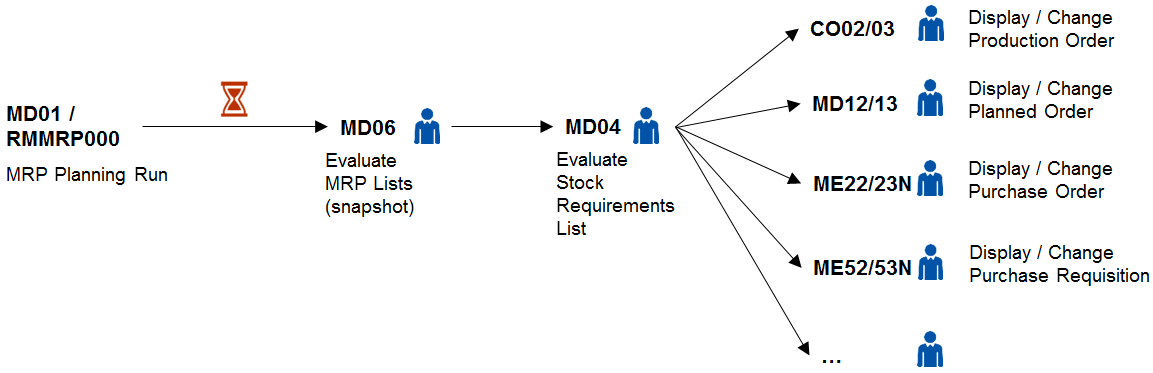

The long execution time of the MRP planning run creates another problem: the generated results are just a snapshot of the demand-supply and material situation at the time of the run. As soon as the material situation changes, the MRP results become outdated immediately. In addition to the challenge of working with an outdated snapshot, the Material Planner has to use multiple ERP transactions to manage material shortages, and for each shortage, multiple transactions are needed to complete the solution (see Figure 1).

Figure 1: The MRP process before HANA

The main responsibility of a Material planner is to ensure the right materials are in the right place at the right time so that customers receive their orders on time. How can he achieve this in real-time with those limitations of using an outdated snapshot and complex user interface? If planning decisions are often based on incomplete, inaccurate and often outdated supply chain information, the results are delayed responses, wrong decisions and negative impacts to manufacturing execution. The process today is inefficient and manually intensive.

How can SAP HANA help?

SAP HANA improves the efficiency of the MRP planning run by eliminating the long batch runs and unnecessary aggregates with the ultimate goal of having real-time access to material data. Can we achieve this for MRP? With SAP HANA, we can!

The MRP run has been improved over the last two decades in terms of performance, getting 10% or 20% faster with each improvement. But those improvements never removed the need for batch runs, replicated data and pre-computed aggregates. Now with SAP HANA, the performance has improved several orders of magnitude, allowing the MRP planning run to be executed in real-time.

Figure 2: The MRP process with HANA

And what is the result? A Material Planner can now forget about running reports. Instead, he has immediate and direct access, not to the data as it was at the beginning of the day or the end of last week, but to the latest demand-supply situation in real time. The planning run can be now executed in minutes or even seconds for a given material.

What about the user experience?

Redefining MRP is not only about improving the performance of the planning run; it is also about introducing a completely new and transformational user experience for the Material Planner. In order to change the game, the existing process has to be changed. SAP’s answer is the new Smart Business for MRP (see Figure 3). The Smart Business for MRP is an example of the next generation of SAP Fiori Apps and a perfect illustration of how these apps can recreate processes, even ones that are 30 years old.

Figure 3: The new MRP Cockpit

Smart Business for MRP enables the Material Planner to monitor the material shortage situation and solve issues on time and in real-time. He can ensure that sufficient supplies have been planned to cover external requirements — whether for sales orders or stock transfer orders, for example. He can review material situations and prevent and address material shortages before they happen.

The new Smart Business for MRP introduces new capabilities like the ability to view inventory position across multiple plants or analyse component requirements with real-time analytics.

An example of this is the analysis of materials with shortages (see Figure 4). Traditionally, to identify solutions to material shortages, several ERP transactions had to be executed, which were time consuming in the past. In the new Smart Business for MRP, data is pulled in real time from all areas of material management including procurement lead times, inventory stock availability, lot sizes, manufacturing scheduling and sales orders across multiple sites. The system goes one step further and suggests potential solutions for the shortage. By using HANA, each solution is evaluated in real-time and the user can preview the potential viability and impact before accepting a solution.

Figure 4: Insigt-to-action in the MRP Cockpit

Key takeaways?

The new MRP run powered by SAP HANA enable the MRP planner to have immediate and direct access to the latest data in real time. The MRP Cockpit allows for quick and meaningful insights and enables the MRP planner to take immediate action. Everything is now fast and simple!

“Simplify everything. Do anything.” – this was the key message from CEO Bill McDermot at the recently ended SAPPHIRE 2014.

This is simplification at its best!

This post originally published on saphana.com and republished with permission.

- SAP Managed Tags:

- SAP HANA,

- SAP S/4HANA

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

152 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

208 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

88

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

- Reimagine Self-Serving SAP Technical Upgrades in Enterprise Resource Planning Blogs by Members

- Higher Education & Research in S/4HANA Cloud Public Edition 2402 in Enterprise Resource Planning Blogs by SAP

- Artificial Intelligence and Technologies in SAP S/4HANA Cloud Public Edition 2402 in Enterprise Resource Planning Blogs by SAP

- Revolutionizing Business Operations: A Deep Dive into SAP S/4HANA Cloud’s end to end Solution for Service Orders, Subscription Billing, and Entitlement Management in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 8 | |

| 6 | |

| 5 | |

| 4 | |

| 4 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 |