- SAP Community

- Products and Technology

- Supply Chain Management

- SCM Blogs by SAP

- The HP Story - Planning and Execution With SAP SC...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Today at Sapphire I listened to a great session by Balaraj Pudota, the Development Manager for Global Supply Chain Systems at Hewlett Packard.

The first thing that hit me was the sheer scale of the HP deployment which has over 1,700,000 SAP users in more than 50 countries. This represents 46% of SAP licenses on HP converged Infrastructure. As you would expect, HP have a broad SAP landscape with systems running at a very large scale across ERP, CRM, GTS, APO, BW, etc.

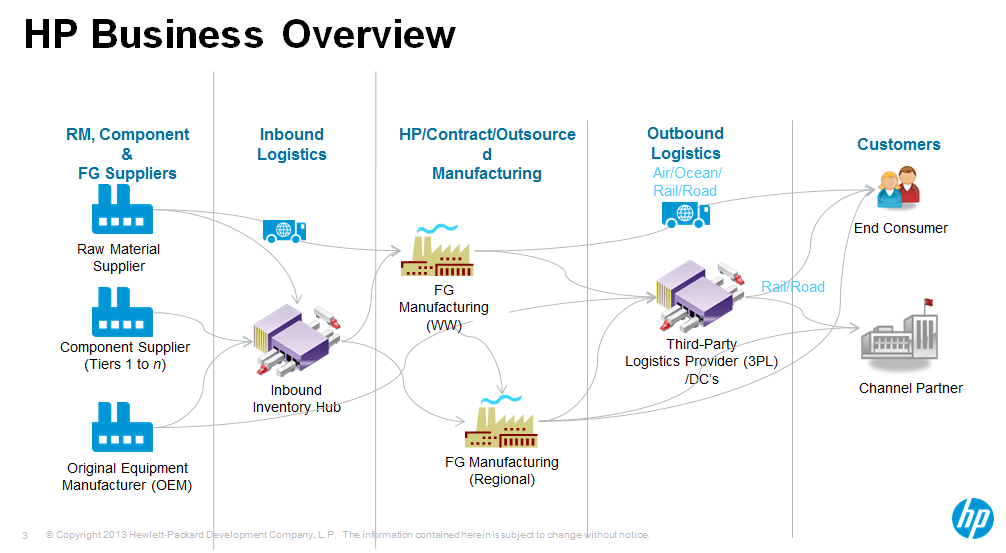

HP's complex supply chain

Balaraj showed a high level picture of the complex HP supply chain (see picture). He highlighted that every 60 second HP produces 105 PC’s, 88 printers, 880 ink carterages, 7 network devices, and 7TB of storage.

HPs' complex, multi-level global supply chain leads to many challenges:

- Righ Sourcing the product / location between DCs as well as DCs and Factories and also including alternate products

- Outsourced Fulfillment requires visibility to outsourced inventory, the ability to prioritize orders, and a fact-based order commit and scheduling

process - Transportation Modes that can enable commit to future receipts, taking into account short lead times to optimize scheduling of transportation and shipments

- Backlog Prioritization and Allocation that takes into account constraint management, rescheduling and product allocation and adjustments

- Service Level Agreement Management that supports customers agreed SLA’s and alerts that drive prioritization decisions.

- Analytics to monitor shortage reporting and metrics at product and component level.

Leveraging Global Available to Promise

HP leverage SAP’s Global Available to Promise at HP to deliver “fact based, real-time ATP checks”.

Today about 70% of HP products are shipped using GAtp. The global PC business is driven by a single sales order commit tool. This enables a uniform regional business process around supply allocation that allows for multiple execution models.

This is all enabled through a tightly integrated solution with the SAP ERP (ECC) solution.

Benefits

Balaraj touched upon some of the business benefits of the implementation:

- Confidently commit sales orders against actual supply across all fulfillment models.

- Backlog management has improved due to simulation capabilities

- Enhanced reporting and analytics.enabling business to view supply and allocation shortages

- Improved commit and fill rates

- Priority order release through commit simulation

Another great overview at #SapphireNow

Follow me on twitter @howellsrichard

- SAP Managed Tags:

- SAP Sapphire,

- High Tech,

- SAP Advanced Planning and Optimization

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Business Trends

169 -

Business Trends

23 -

Catalog Enablement

1 -

Event Information

47 -

Event Information

2 -

Expert Insights

12 -

Expert Insights

35 -

intelligent asset management

1 -

Life at SAP

63 -

Product Updates

500 -

Product Updates

60 -

Release Announcement

1 -

SAP Digital Manufacturing for execution

1 -

Super Bowl

1 -

Supply Chain

1 -

Sustainability

1 -

Swifties

1 -

Technology Updates

187 -

Technology Updates

14

- RISE with SAP Advanced Logistics Package in Supply Chain Management Blogs by SAP

- Drive productivity, safely and sustainably, with SAP manufacturing solutions in Supply Chain Management Blogs by SAP

- RISE with SAP advanced asset and service management package in Supply Chain Management Blogs by SAP

- 5 Reasons why Planners Should Consider the RISE with SAP Advanced Supply Chain Planning Package in Supply Chain Management Blogs by SAP

- SAP Transportation Management Analytics in Supply Chain Management Blogs by SAP

| User | Count |

|---|---|

| 9 | |

| 7 | |

| 4 | |

| 3 | |

| 3 | |

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 |