- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by SAP

- Automation in Overdrive: The Good, The Bad, and t...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Update: Coffee Break with Game Changers on SAP Radio hosted by @bonniedgraham held the second part of the discussion on Automation in Overdrive with guests from MESA, IDC, Deloitte, and myself.

Opening Quotes of today's shows:

Mike Yost, MESA International: “Governmental initiatives, like Germany’s ‘Industry 4.0’ and US National Network for Manufacturing Innovation, are shining a light on the importance of advanced technologies in manufacturing, but we’re still a long way away from putting the pieces together correctly.”

Kimberly Knickle, IDC Manufacturing Insights: “I was taught that the way of progress was neither swift nor easy.” (Marie Curie)

Jeff Jackson, Deloitte: “We cannot solve our problems with the same thinking we used when we created them.” (Albert Einstein)

Chuck Pharris, SAP: “The future of automation will be a shift from robots replacing humans in jobs to humans working beside robots.”

Listen to the replay:

Part 1 - Feb 4 HERE

Part 2 - Today HERE

Original Blog:

Automation has been a part of manufacturing industries for over 30 years. Entire petroleum oil refineries and oil fields are almost fully automated and can be ran from remote locations and even offshore. Robots have found their way into more and more manufacturing in welding, assembly, product inspection, and packaging since the first one, Unimate, went to work at a GM factory in 1961. Now, 90% of robots work in manufacturing, and half are making automobiles. They found their way into the home doing things like vacuuming the floor by themselves. Robotics and automation are considered the future of what is described as the next industrial revolution, Industry 4.0.

The Good

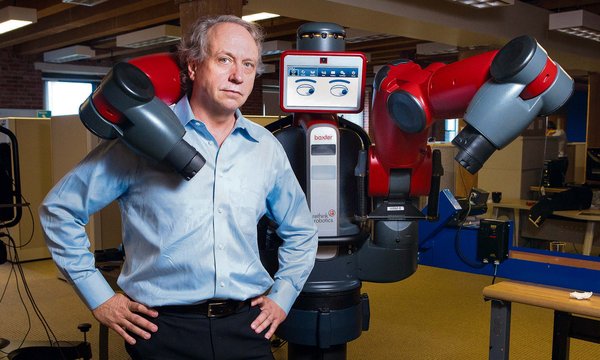

We are entering what some consider a golden age of robotics. Some see examples that will make our lives easier. Robots are getting smarter and more capable. In manufacturing, we have traditionally been separated from robots. They either did jobs that were inherently hazardous or they themselves presented a danger to workers, which defined their roles and uses. Rodney Brooks first introduced the roomba vacuum cleaner has now created Baxter, credited with potentially revolutionizing US manufacturing. Baxter is low cost, compared to previous industrial robots, at $25K, but the thing that distinguishes this new class of robots is their ability to learn. They are designed to be flexible enough and interact with humans to train them and work with them. This ability at this cost can really be a game-changer in spite of the fact that making a robot is still, “darn hard”.

The Bad

Along with the low-cost robot at home to clean your house and wait on you while you watch TV, there are potential downsides to this capability. In previous industrial revolutions, the increased productivity has gone disproportionately to capital versus labor. This is a currently distributing trend attributed to growing inequality. The Wall Street Journal says, “Good news…if your job is boring, a robot may take it”. A recent article in the Economist reviewed research that indicates 47% of jobs in America are at high risk of being taken by robots. These are not just assembly line or Amazon warehouse jobs either. They are service jobs like fast food you might not previously thought about. Different people speculate which jobs are at greater risk here, here, and here. These include loan officers, receptionists, paralegals, retail salespersons, taxi drivers, security guards, and even your local bartender. In fact, some are considered 100% chance of being replaced:

- Title examiners

- Mathematical technicians

- Insurance underwriters

- Watch repairers

- Tax preparers

The future, however, is far from certain. In Japan, humans are taking back jobs from robots because they can innovate on the job.

The Ugly

There is of course the really ugly side of potential of killer robots.

I recently had the privilege of participating on an episode of, Coffee Break with Game Changers radio, hosted by Bonnie Graham, with a very distinguished group of people including Mike Yost with MESA, Jeff Jackson from Deloitte, and Bob Parker at IDC on Automation in Overdrive (replay here). We discussed many of the pros, cons, and challenges of manufacturing trends and the impacts of automation in overdrive. Tune in this week to see who argues the Good, the Bad, or the Ugly.

Join us for the continuation of this discussion…..

We are going to pick the conversation up again this coming week on Wednesday, May 28th, at 9:00 am Eastern. The page to listen will be posted on Monday evening and I will edit this blog, but you can also check on the main radio page http://www.voiceamerica.com/show/1981/coffee-break-with-game-changers.

If you are coming joining us at SAP SAPPHIRENOW in Orlando next week, there are many sessions on related topics of Internet of Things and Industry 4.0. Click on the titles to add to your agenda builder:

Big Data & Analytics

• Make the Most of Big Data Applications in Manufacturing

• Improve Performance and Product Quality with Real-Time Metrics

• Simplify Analytics Reporting by Integrating Data with Standard Office Tools

• Streamline Operational Data Access and Analysis for Business Users

• Turn Oil Field Operations Data into Action with Mobile Solutions

• Run Planning and Manufacturing Operations on a Platform Built for Speed

Internet of Things

• Benefit from the Internet of Things in Manufacturing

• Embrace the Future of the Connected Factory Now

• Join the Next Industrial Revolution in Manufacturing

• Connect the Machines That Do the Work

• Enter the Fourth Industrial Revolution Through the Internet of Things

The Future of Work

• Prepare Today’s Manufacturing Workers for Tomorrow

• Optimize the Shop Floor for a Next Generation of Employees

- SAP Managed Tags:

- SAP Sapphire,

- MAN (Manufacturing)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

Artificial Intelligence (AI)

1 -

Business Trends

363 -

Business Trends

21 -

Customer COE Basics and Fundamentals

1 -

Digital Transformation with Cloud ERP (DT)

1 -

Event Information

461 -

Event Information

24 -

Expert Insights

114 -

Expert Insights

154 -

General

1 -

Governance and Organization

1 -

Introduction

1 -

Life at SAP

415 -

Life at SAP

2 -

Product Updates

4,685 -

Product Updates

215 -

Roadmap and Strategy

1 -

Technology Updates

1,502 -

Technology Updates

89

- Deep Dive into SAP Build Process Automation with SAP S/4HANA Cloud Public Edition - Retail in Enterprise Resource Planning Blogs by SAP

- SAP Enterprise Support Academy Newsletter March 2024 in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release – Part 2 in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release – Part 1 in Enterprise Resource Planning Blogs by SAP

- SAP Business ByDesign 2023 year-end review and outlook 2024 in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 12 | |

| 11 | |

| 7 | |

| 6 | |

| 6 | |

| 4 | |

| 4 | |

| 4 | |

| 4 | |

| 3 |