- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- SAP REM full cycle scenario with basic step

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Repetitive Manufacturing(REM)

Company manufactures product in large numbers and production is quantity based and period based not order based.

- Repetitive manufacturing is mainly used for the production scenarios with high product stability, high repetition rates, and low product complexity.

- In master data production versions and cost collector is must where this is not mandatory in discrete manufacturing.

Application Areas:

Industry Type: Mechanical engineering, Consumer goods, electronics, and many more

- Tact-based Flow manufacturing

- Period based production

- Mass production

Difference b/w Discrete and REM

REM Prerequisite

- REM Profile

- REM Indicator

- Production Version

- Product Cost Collector

SAP REM Full Cycle scenario

Basic Data:

- Plant : TAJA

- Company Code : 1000

- Storage Loc : TA01

- Material created :

Sir No | Material | Material Type |

1 | AIRCOIL | FERT |

2 | CORE | ROH |

3 | SLEEVE | ROH |

Repetitive manufacturing profile to control how you want to carry out planning and back flushing in repetitive manufacturing

Basic control parameter of the REM Profile

- Whether you want to backflush activities.

- Whether you want to work with reporting points in make-to-stock REM

- How you want to process errors which occur when back flushing

Create the REM Profile:

SPRO Production Rep manufacturing Control Data Create REM Profile Assistant (T-Codes: OPP3/OSP2)

With help of the REM profile assistant create the Make-to-Stock REM Profile “TJ” (REM Profile for plant TAJA) here GI backflush at GR posting check mark and RP backflush is mandatory/Optional(as per requirements)

- Here Planned order reduction period is given 3 , so In this period system reduces all planned orders and run schedule quantities in the period

reduction

- Here below mention all movement type set for the REM profile TJ

- Create the finished material Air coil with Repetitive mfg. indicator and REM profile TJ maintained in material master see view MRP -4 , ( MM01)

- Please create and maintained the BOM(CS01) and routing/Rate routing (CA01/CA21)

- Rate routing for top material Air Coil and assigned control key to the operation see in below pic, (T-codes: CA21), here control key using for UK01 and UK02 for operation. (Standard SAP control key with milestone confirmation is PP01)

- Create the Control key UK 02, with ‘milestone confirmation’ with help of the T-codes OP67.

- The milestone confirmation is a special form of confirmation, in which the confirmation of one operation causes other operations or suboperations to be automatically confirmed at the same time.

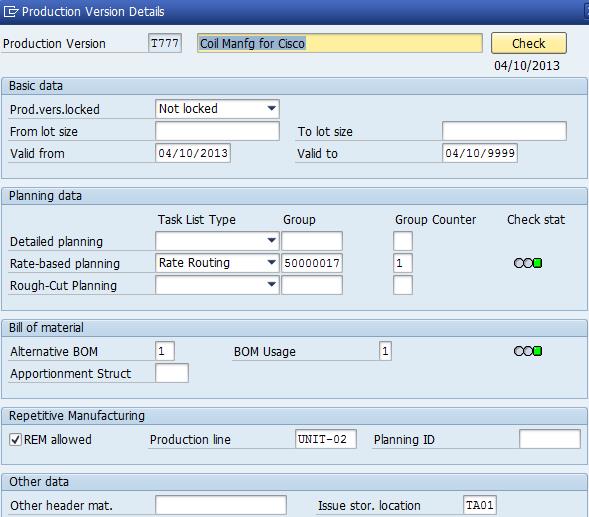

- Create the Production version T777 for finished material(Air coil) with help of material master change (MM02), and in Selection method put indicator 2 or 3.

- Production version is combination of the BOM and Routing/Rate Routing. Overview of the production version T777, more than one production version created as per requirement and make sure current prod. Version not locked.

- As per REM profile selection for the product cost accounting

There are two different type of cost accounting exit.

- Standard cost estimate per material.

You can create this cost estimate once in a period with reference to a routing. You can post activities on the basis of this cost estimate if you produce a material using only one production version in one period.

Using T-code: CK11N do the standard cost estimate for current date and period, And release this standard cost estimate through T-code: CK24.

- Preliminary costing for the product cost collector.

You can create this cost estimate per production version. This makes sense if you produce one material using different production versions and routing in one period.

Using T-code:KKF6N for create Preliminary cost estimation in REM.

- Here we selected preliminary costing for the product cost collector in REM profile

- Create the Plnd.Ind.Reqmnt(PIR) for the finished material Air coil with help of the T-code: MD61

- See the below pic of the stock requirement list after generating the demand without run MRP. (T-codes : MD04 )

- After run the MRP with help of the MD02 for finished material(Air Coil), MRP element is RS and order type is PE

- In REM, we can do backflush(REM Confirmation) through planned order or finished material using MFBF, here we selected the planned order

- Checking with Post with correction in tool bar of REM confirmation page before saving and get the detail information of the all transaction variant with all detail.

- After saving system posted GR and GI document(As per REM profile setting GR and GI done at same time)

- After the confirmation of the both planned order, good receipt done automatically and available stock is 20. MD04 Screen

- With help of the Document overview on MFBF tab, we know the detail of the GR and GI transaction, and with help of the Reverse tab we can reverse the process of movement and material back to the stock.

I prepared this document for the understand the basic step of the SAP REM process, and i hope this document helpful to clear the basic concept of the REM process.

Request to expert please correct me if any thing missing or wrong in this document.

Umesh Mali

SAP PP-QM Consultant

- SAP Managed Tags:

- MAN Production Planning (PP)

- « Previous

-

- 1

- 2

- Next »

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Advance Return Management complete configuration(SAP ARM) in Enterprise Resource Planning Blogs by Members

- Output Type SPED trigger Inbound Delivery after PGI for Inter-Company STO's Outbound delivery in Enterprise Resource Planning Blogs by Members

- SAP ERP Functionality for EDI Processing: UoMs Determination for Inbound Orders in Enterprise Resource Planning Blogs by Members

- Beyond Basic (1): Certificate-Based Authentication in Enterprise Resource Planning Blogs by SAP

- KANBAN issue straight to cost center after status FULL in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |