- SAP Community

- Products and Technology

- Additional Blogs by Members

- SAP Reverse Application Summary

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

As we can know that there are many kinds of “Document” in system to record our application, which can also be taken as prove. In daily business, we might need to reverse some of the documents to re-work our business, for making it right. Now I am going to summarize what has occurred to me for “Reverse” and what the T-code can be used to perform these kinds of “Reverse”.

First of all, we should know that there can be two “clusters” of “Document” in system, also reflecting our daily business: the “Material Document” and the “Accounting Document”. I will list out all their related “Reverse” Scenario, what we can do to solve it and how we gonna perform in system, of these two clusters.

In this one, I will introduce the Reverse Application about the “Material Document”.

“Material Document” related: these can be all the material movement under Supply Chain Management.

By module:

SD

Cause the document flow of SD is mainly like this: Sales OrderOutbound DeliveryInvoice (Billing)

So the Reverse performance should also follow the opposite direction of the flow above.

I- VF11---Cancel Billing Document

Check the Flow

Then to reverse the Outbound Delivery.

II- VL09---Reverse Goods Movement

We can delete the Picking amount to “0” to make the picking not started.

———————————————————————————————————————————————————————————————————

Normally, in China, when the Billing has been created, the “Fapiao” can be printed via Golden Tax machine. In accounting book, the sales revenue is debited automatically.

If the return of sold goods occurs, we normally use the “Return” process in SD module to cover this process and related “Credit Memo” will be issued. The “Fapiao” will be cancelled by the “Rubric strike a balance” process manually. So the above cancellation should be rare in daily business after the goods have been successfully posted.

While the changing or reverse of Delivery before Billing should be needed as a possible reverse.

———————————————————————————————————————————————————————————————————

MM

MIGO--->MIRO

Then we might have MIGO for Goods Receipt from our vendors.

I- MR8M---Cancel Invoice Document

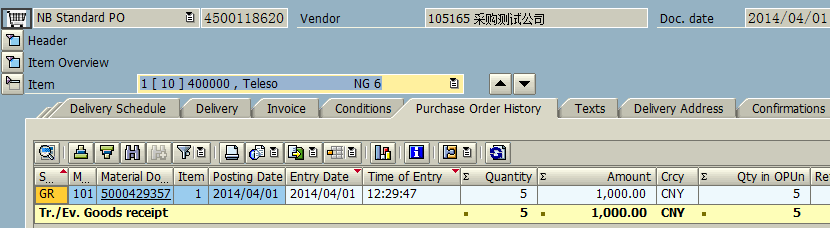

The result shows the situation after MIRO has been done for a PO.

When MR8M, Select the Reversal Reason and Posting Date, then we have:

———————————————————————————————————————————————————————————————————

This reverse can be seen when the FI has perform the invoice with wrong amount or with wrong invoice itself sent from vendor. The reverse can be posted to previous period by SPRO setting allowing. Normally this should not be legal or applied by the Bureau regulation, or challenged by Audit officer. See more about monthly closing in China related document.

———————————————————————————————————————————————————————————————————

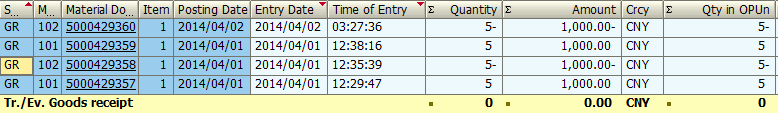

MBST---Cancel Material Document (MIGO Material Document with opposite movement)

II- MIGO PO with 102 movement type: when Receipt number or time need to be changed.

———————————————————————————————————————————————————————————————————

The difference between them, (mainly basing on the business purpose):

When using MBST, that means we need to reverse what we have done with the movement itself, with the exact “value” and “amount” at the time when you did the business movement in system. And if the OBYC setting or related FI/CO setting have been changed, the MBST will follow what the system has been set by now.

While using MIGO with 102, or we say the “opposite movement” type to 101, we are moving the material with the “value” now, and if the material is valued with “V” price, its related 102 movement “value” price would be different. And also, we can change or modify the 102 movement amount figure, not with fixed figure of its 101 movement.

———————————————————————————————————————————————————————————————————

PP

Then we might can issue our materials to production order (Discrete Manufacture) or “workshop” storage location for Back flush. These all can be treated as MIGO and their reverse can be done like the part in “MM” above.

But for the production confirmation, this will consume the components and increase the finished products, after goods receipt with MIGO.

———————————————————————————————————————————————————————————————————

When talking about Production and Planning in SAP, we should always split the topic into 3: Discrete Manufacture, Process Manufacture and Repetitive Manufacture.

Discrete Manufacture: we use Production Order to perform the production in system, so mainly the reverse work is for the Issue components and reverse the Receipt finished products: after the REL of the production order, we cannot reverse the REL status itself, only by TECO or DLF set can we ignore or dismiss the Production Order in MD04 list.

Repetitive Manufacture: we use Production Version to assign the BOMS, rate routine and production line (work center) to the finished products. We send the related components to the workshop storage location and consume (back flush) them then receipt the finished ones to its storage in no time. So the reverse can be done with the back flush performance. (The movement of the components to workshop can be treated as normal MB1B and reverse by MBST.)

Process Manufacture: hope I can have chance to know this in the future.

———————————————————————————————————————————————————————————————————

MIGO--->Confirmation

I- CO13---Cancel Production Order Confirmation

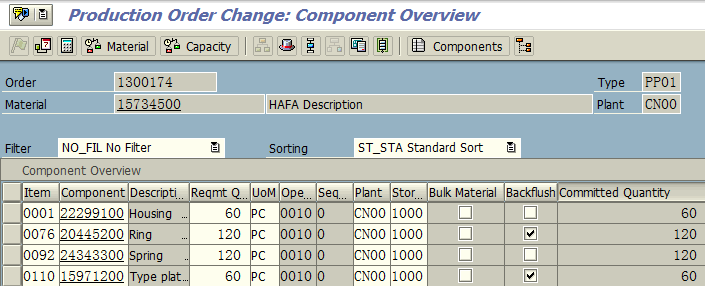

First show the components in the Production Order:

In which, there are2 materials treated as “Bulk Material”, so only item “0001” and “0092” show with the confirmation CO11n:

Adding “0076” and “0110” when confirmation in Goods movement:

And final confirmation,

MIGO with order

In this case, we have to MBST or MIGO with order 102 first, to “return” the finished goods first back to our production line.

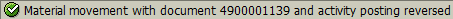

Then the CO13 can perform:

Also the components can be “sent” back to its original storage location with the opposite movement type “262”.

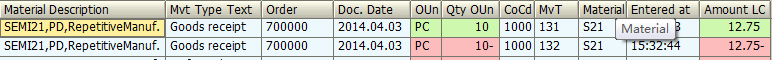

II- Repetitive Manufacture show the material movement like below.

MF41---Cancellation of Confirmation

Choose the material, plant, then we can see like this:

Then

Check the MB51 then we can see

———————————————————————————————————————————————————————————————————

When for discrete manufacture, we do the reverse mainly because of the wrong input about the yield amount or updating duration time of the related operation. And for the physical inventory, we usually reverse the HALB to ROH for easier calculation.

When for repetitive manufacture, not only we reverse the HALB to ROH when physical inventory, we also should MBST the components from workshop to its storage location for external procurement.

———————————————————————————————————————————————————————————————————

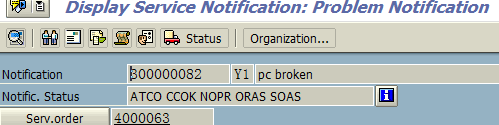

CS

The Customer and Service module is quite like the combination between SD and PP module.

That is to say, the process is all started by A notification, the we have two ways for dealing the process: Service Order and Sales Order.

That is to say,

I For the Service Order, we will do the confirmation at the last steps to confirm the components and time consumed for completing this Notification.

IW45---Cancel PM Order Confirmation

Then it is like the CO13 process and you can enter the Cancellation or Reverse reason for reference.

———————————————————————————————————————————————————————————————————

This Reverse can be very common when the CS users are either not so familiar with the repair work that they have chosen the wrong components, or the components they want to consume are not actually available at the warehouse.

II When for Sales Orders, you can look into the above SD Reverse application.

———————————————————————————————————————————————————————————————————

To conclude, the above Reverse application are the ones which I have actually used in my project. The Blue part is the actual business scenario for the time when we should use these reverse in daily business: all the SAP application reflect your business work. So you cannot just reverse what you have processed in the system as you want to, you need to be approved and authorized.

The modules I have introduced are SD, MM, PP and CS. Hope in the future I can introduce more like QM or PM.

- SAP BW/4 - revamp and true to the line 2024 in Technology Blogs by Members

- Extract blob data (PDF) from CAPM using python library of Document information extraction service. in Technology Blogs by Members

- SAP Cloud ALM and Identity Authentication Service (IAS) in Technology Blogs by SAP

- Consuming SAP with SAP Build Apps - Mobile Apps for iOS and Android in Technology Blogs by SAP

- Demystifying the Common Super Domain for SAP Mobile Start in Technology Blogs by SAP