- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Root Cause Analysis through 5-Whys

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Introduction

Many of us are aware that Breakdowns leading to Production losses draw attention of Senior Management as well as QMS audit people. Very frequently asked question by these authorities is What is the Root Cause? Also Many of us know about a very common and effective approach to reach at this Root Cause is through the method of asking Why 5 times. (5-Why method). It is said that by receiving answer to the 5th Why on the Breakdown reason, we would be arriving at the Root Cause. (It is quite possible that we arrive at Root Cause well before answering the 5th Why.)

Objective

We are discussing in this document about an idea implemented to map this process of Root Cause Analysis, making use of Catalogs & Codes. We will be able to show to the Authorities, the Root Cause Analysis done on vital breakdowns.

Here we see how to go about it

Preparation

Make few Code-Groups and Codes as under through Tcode QS41 (and Transport to other clients)

Root Cause Analysis

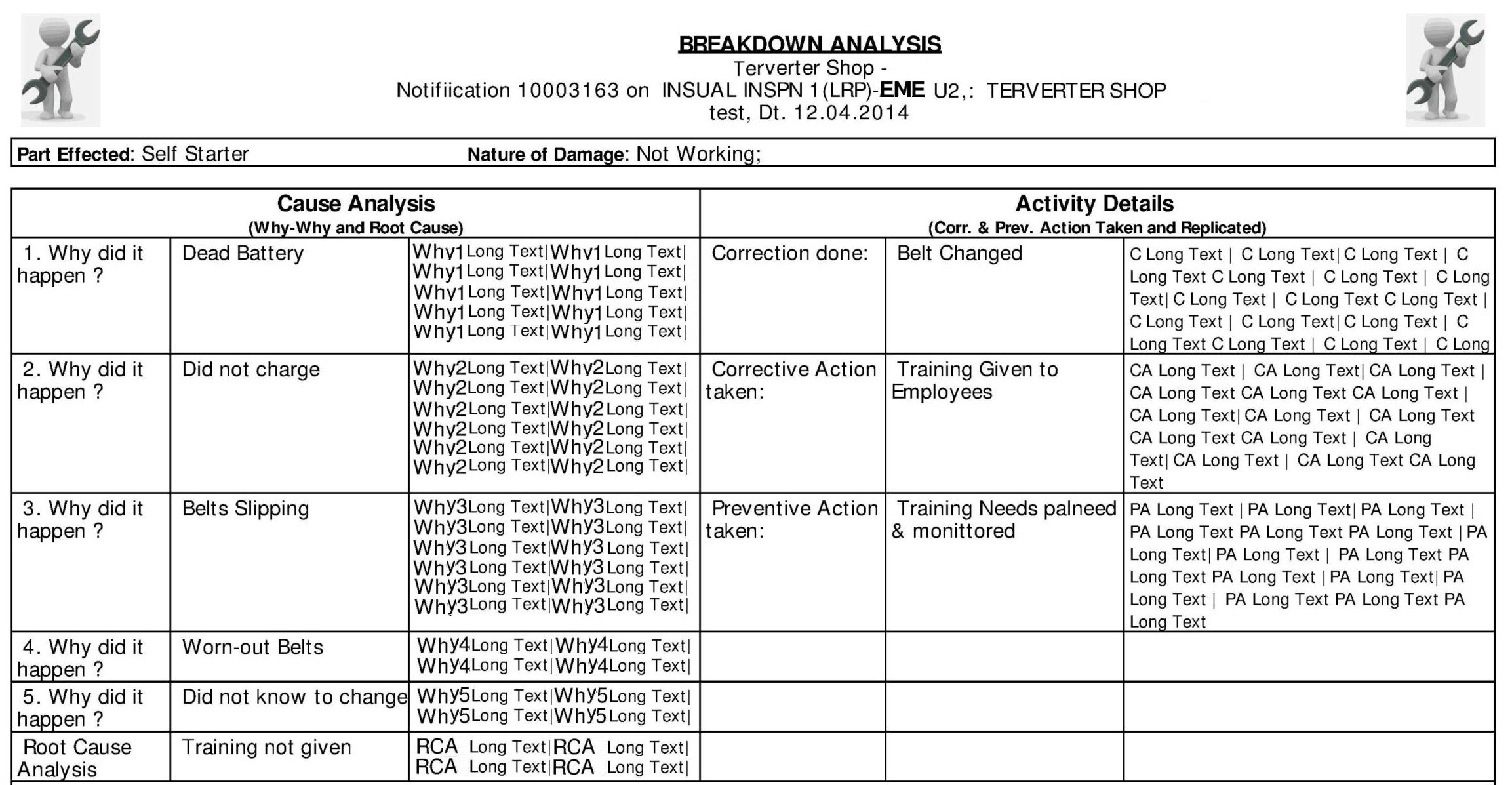

For demonstration, we have taken a simple case of EME vehicle not starting, on which we had already created a Malfunction Notification. See this Graphic to understand the 5-Why Analysis.

Now let's do it in the system with the help of the codes created above. Go to the Catalogs & Codes Tab of this Notification, give the Object part and Damage details and enter the Causes Tab page. See the picture how we used the above codes to perform 5-Why analysis .

So the Root Cause we have Arrived at is Training not Given. Note: If needed, you can write long-texts against each code-Text.

Now Go to Activities tab and record this way:

Here too Long texts can be used.

All done.

Now we can show the Authorities, the Analysis we do on vital Breakdowns.

Further, to show it in an impressive Lay-out, and system generated PDF formats, we can go for a Smartform as I opted for (shown below)

I need not explain the picture above, it is self-explanatory. This Samrtform was integrated to custom reports of Breakdown Analysis When clicked on a CAPA cell against a Notification, system presents you the above screen.

Note:

The coding part (QS41), will be customized by Readers as per their situation. Bottom line is how we map the 5-Why process using the SAP objects. Hope this share will be useful to members.

Thank you

KJogeswaraRao

- SAP Managed Tags:

- PLM Enterprise Asset Management (EAM)/Plant Maintenance (PM)

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

learning content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Planning of Business Entities (Universal Allocation, Internal Allocation, EC-PCA) in Enterprise Resource Planning Q&A

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

- How to add characteristics for profitability analysis? in Enterprise Resource Planning Q&A

- Status and Progress Analysis in Enterprise Resource Planning Q&A

- Print customer specific inspection plan results on Outbound Certificate of Analysis in SAP QM in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |